Conducting concrete using polyaniline as conducting phase and preparation method thereof

A conductive concrete and polyaniline technology, which is applied in the field of composite materials, can solve the problems of lack of electrical conductivity, high compressive strength, environmental stability, limited application range, hard and hard to wear, etc., and achieves low production cost, good environmental stability, and synthetic low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

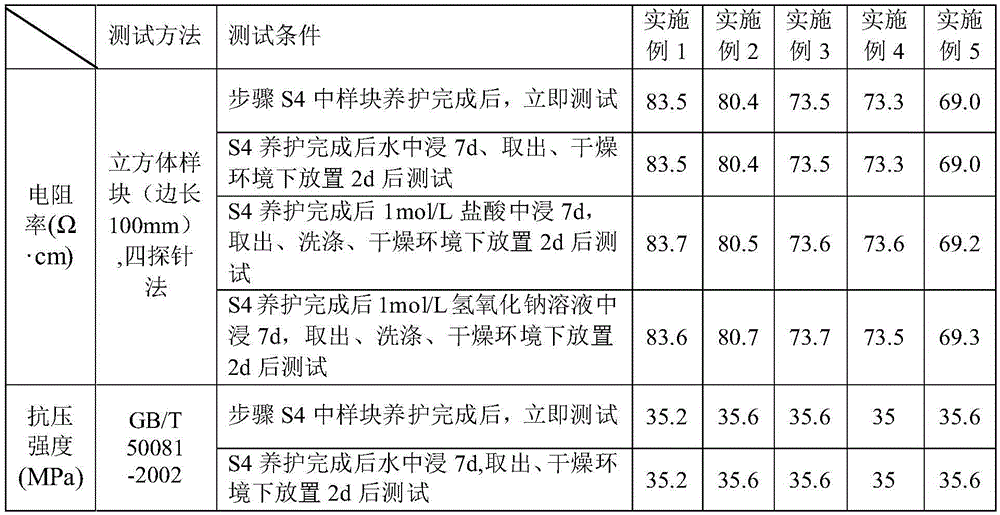

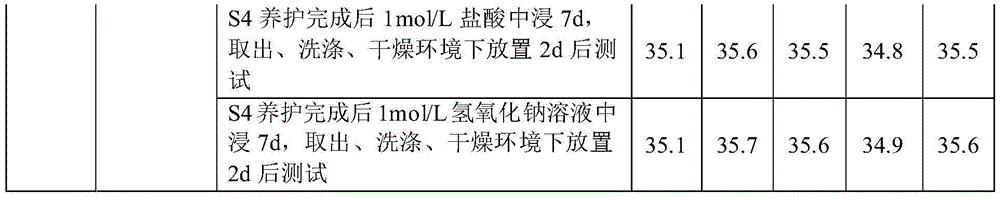

Examples

Embodiment 1

[0027] The preparation method of the conductive concrete with conductive polyaniline as the conductive phase comprises the following steps:

[0028] The parts by weight of each raw material are all calculated in the same weight unit,

[0029] S1: Mix 90 parts of conductive polyaniline (1-5S / cm), 110 parts of water, and 0.9 parts of dispersant Tego760W, and then perform ball milling dispersion treatment to obtain a dispersion of polyaniline in water;

[0030] S2: 200 parts of composite cement, 100 parts of river sand and all the dispersions prepared by S1 are added together in the mixer and fully stirred to obtain a uniform mixture of each raw material;

[0031] S3: Pour the mixture prepared in S2 into a mold for sample preparation, leave it at room temperature for 1 day after sufficient vibration, remove the mold, take out the sample block, and put it into a concrete curing box for standard maintenance;

[0032] S4: Take the sample block in S3 out of the curing box, and place...

Embodiment 2

[0034] The preparation method of the conductive concrete with conductive polyaniline as the conductive phase comprises the following steps:

[0035] The parts by weight of each raw material are all calculated in the same weight unit,

[0036] S1: 30 parts of conductive polyaniline (1-5S / cm), 70 parts of water and 0.3 part of dispersant Tego760W are mixed and then ball-milled for dispersion treatment to obtain a dispersion of polyaniline in water;

[0037] S2: 100 parts of composite Portland cement, 100 parts of river sand and all the dispersions prepared by S1 are added together in a mixer and fully stirred to obtain a uniform mixture of raw materials;

[0038] S3: Pour the mixture prepared in S2 into a mold for sample preparation, leave it at room temperature for 1 day after sufficient vibration, remove the mold, take out the sample block, and put it into a concrete curing box for standard maintenance;

[0039] S4: Take the sample block in S3 out of the curing box, and place...

Embodiment 3

[0041] The preparation method of the conductive concrete with conductive polyaniline as the conductive phase comprises the following steps:

[0042] The parts by weight of each raw material are all calculated in the same weight unit,

[0043] S1: After mixing 45 parts of conductive polyaniline (1-5S / cm), 79 parts of water and 0.45 part of dispersant Tego760W, ball milling dispersion treatment was performed to obtain a dispersion of polyaniline in water;

[0044] S2: 100 parts of composite Portland cement, 100 parts of river sand and all the dispersions prepared by S1 are added together in a mixer and fully stirred to obtain a uniform mixture of raw materials;

[0045] S3: Pour the mixture prepared in S2 into a mold for sample preparation, leave it at room temperature for 1 day after sufficient vibration, remove the mold, take out the sample block, and put it into a concrete curing box for standard maintenance;

[0046] S4: Take the sample block in S3 out of the curing box, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com