Preparation method of everolimus

A technology for preparing everolimus and liquid phase, which is applied in the field of preparation of everolimus, and can solve the problems of high synthesis cost of synthetic everolimus and high price of sirolimus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

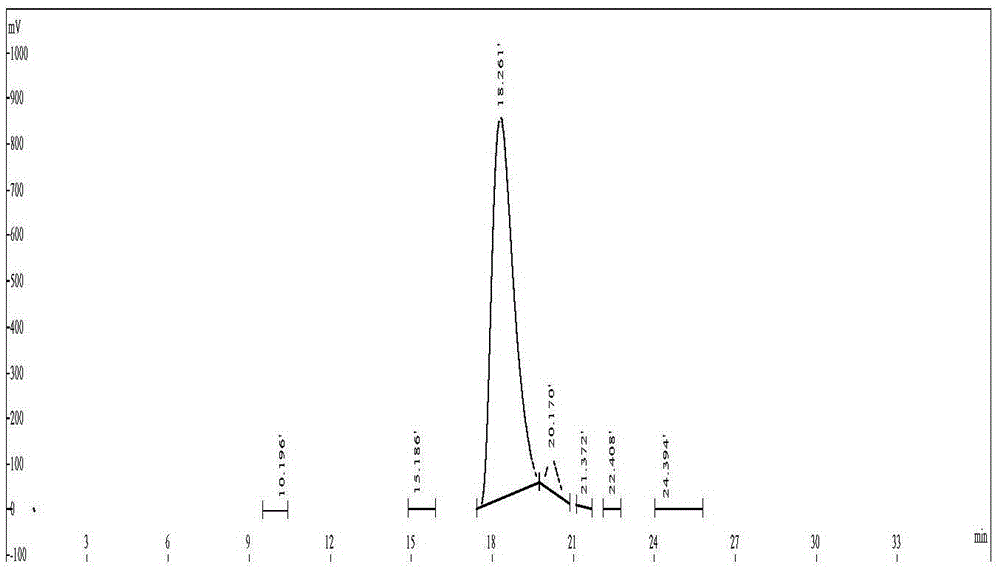

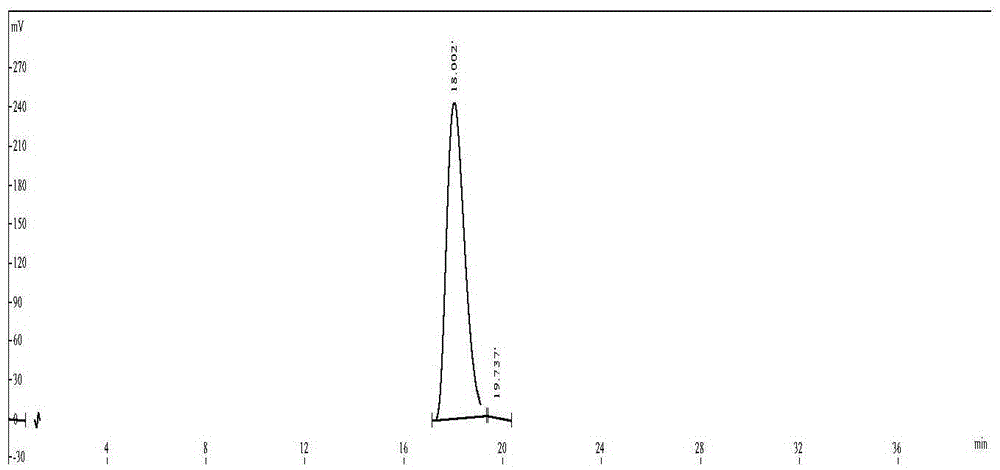

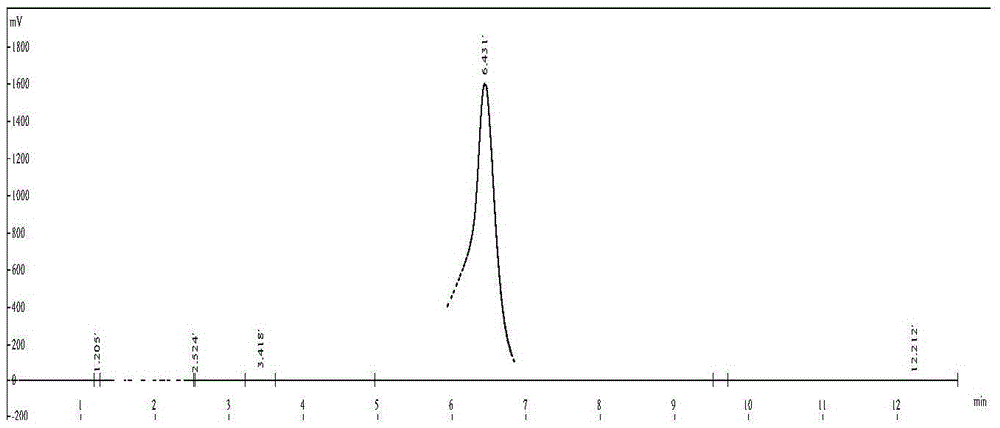

Image

Examples

Embodiment 1

[0075] 1) Preparation of tert-butyldimethylhydroxyethoxysilane

[0076] Under nitrogen protection, triethylamine (5640 g), ethylene glycol (3450 g), and n-hexane (9.1 L) were successively added into a 50 L reaction flask. The system was stirred rapidly and cooled to -5±5°C. Dissolve tert-butyldimethylsilyl chloride (1400g) in n-hexane (4.9L), divide the prepared n-hexane solution into five times on average, control the temperature at -5°C, drop to the above reaction within 0.5-1h After the dropwise addition, the reaction solution was reacted at 0±5°C for 1 hour, and then raised to 20°C for 16 hours.

[0077] Cool the reaction solution to -5±5°C, add purified water (10 L), stir for 5-10 minutes, let stand for 5-10 minutes, and separate the liquids. Cool the organic phase to 0±5°C, add 10% acetic acid aqueous solution (10 L), stir for 5-10 min, let stand for 5-10 min, separate the liquid, and repeat the above operation twice for the organic phase. Cool the organic phase to 0±...

Embodiment 2

[0091] 1) Preparation of tert-butyldimethylhydroxyethoxysilane

[0092] Under the protection of nitrogen, triethylamine (5640 g), ethylene glycol (3450 g), and n-heptane (9.1 L) were successively added into the 50 L reaction flask. The system was stirred rapidly and cooled to -5±5°C. Dissolve TBSCl (1400g) in n-heptane (4.9L), divide the prepared n-heptane solution into five times on average, control the temperature at 0°C, drop it into the above reaction solution within 0.5-1h; dropwise addition is complete , the reaction solution was reacted at 0±5°C for 1h, then raised to 25°C, and reacted for 16h.

[0093] Cool the reaction solution to -5±5°C, add purified water (10 L), stir for 5-10 minutes, let stand for 5-10 minutes, and separate the liquids. Cool the organic phase to 0±5°C, add 10% acetic acid aqueous solution (10 L), stir for 5-10 min, let stand for 5-10 min, separate the liquid, and repeat the above operation twice for the organic phase. Cool the organic phase to ...

Embodiment 3

[0109] 1) Preparation of tert-butyldimethylhydroxyethoxysilane

[0110] Under the protection of nitrogen, triethylamine (5640 g), ethylene glycol (3450 g), and petroleum ether (9.1 L) were successively added into the 50 L reaction flask. The system was stirred rapidly and cooled to -5°C. Dissolve tert-butyldimethylsilyl chloride (1400g) in petroleum ether (4.9L), divide the prepared petroleum ether solution into five times on average, control the temperature at -10°C, drop it to the above reaction within 0.5~1h After the dropwise addition, the reaction solution was reacted at 0±5°C for 1 hour, and then raised to 15°C for 16 hours.

[0111] Cool the reaction solution to -5±5°C, add purified water (10 L), stir for 5-10 minutes, let stand for 5-10 minutes, and separate the liquids. Cool the organic phase to 0±5°C, add 10% acetic acid aqueous solution (10 L), stir for 5-10 min, let stand for 5-10 min, separate the liquid, and repeat the above operation twice for the organic phas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com