Carbon fiber asphalt preparation method and carbon fiber asphalt

A technology of carbon fiber and pitch, which is applied in the field of pitch for carbon fiber, can solve the problems of easily leaving mesophase components and low yield, and achieve the effects of suppressing insoluble components, high yield, and high fiber applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~ Embodiment 10

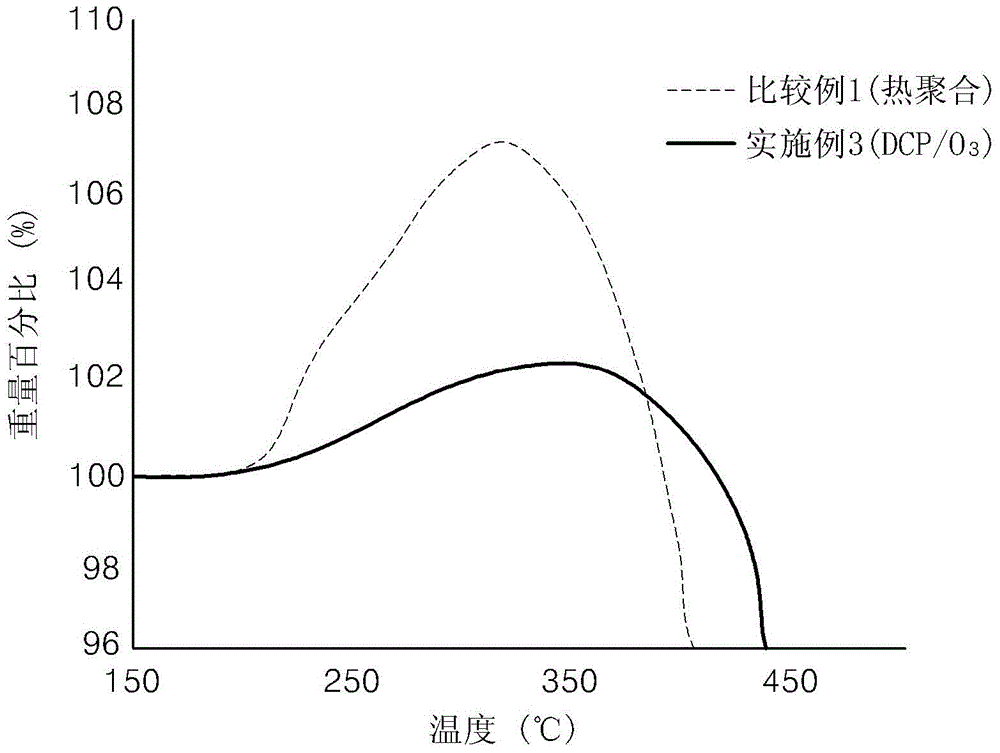

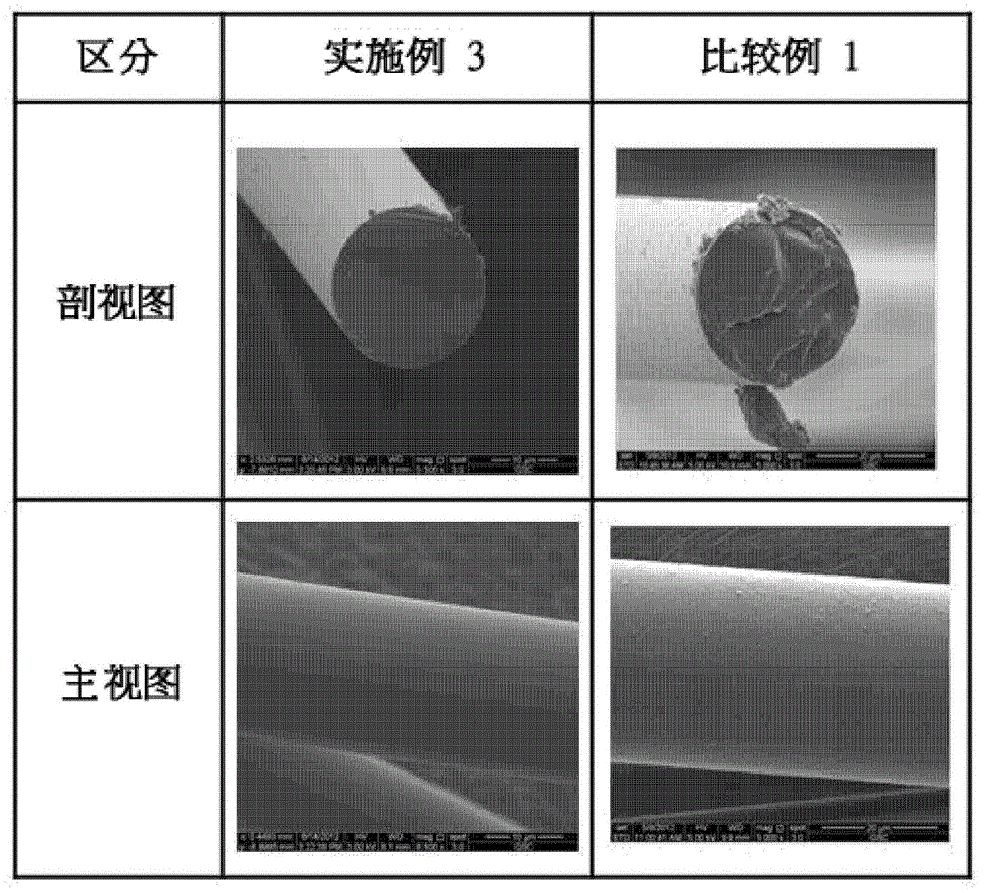

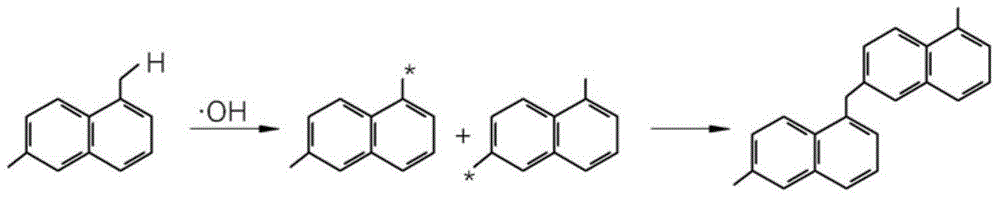

[0066] The reactor is filled with pyrolysis fuel oil (PFO) and dicumyl peroxide (DCP, dicumylperoxide) or hydrogen peroxide (hydrogenperoxide) to mix, and then filled with ozone (O 3 ) The gas is simultaneously heat-treated, thereby proceeding the radical polymerization reaction.

[0067] After the radical polymerization reaction was completed, nitrogen gas at a flow rate of 2 L / min was passed through for a predetermined period of time to remove unreacted or low-reacted molecules, thereby obtaining pitches prepared according to Examples 1 to 10.

[0068] The reaction conditions of each example are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com