A kind of preparation method of health-care camellia oil

A technology for health-care tea and camellia oil, which is applied in the direction of fat oil/fat refining, fat oil/fat production, and fat production, can solve the problems of low oil yield, unsatisfactory deodorization and decolorization effects, etc. The effect of human immunity and improving metabolic rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

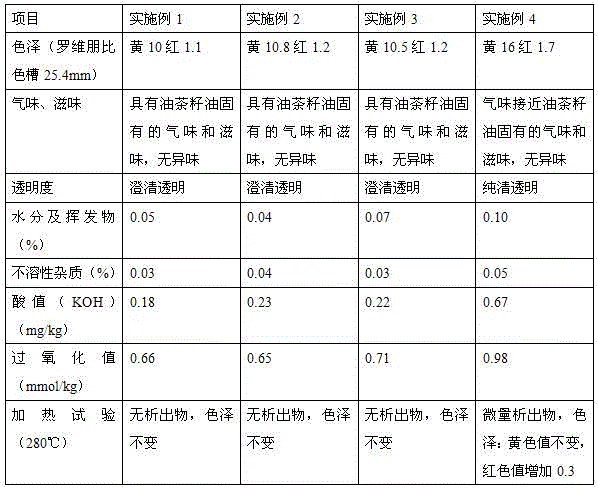

Examples

Embodiment 1

[0032] A preparation method of health-care camellia oil, comprising the following steps:

[0033] (1) Oil extraction: Dried and selected shelled tea seeds are poured into the disc feeder and directly lifted into the oil press; the temperature of the extracted crude oil is 20-30°C, after precipitation, irrigation and precipitation, and then filter to obtain cold-pressed crude oil;

[0034] (2) Alkali refining: put the cold-pressed crude oil in an alkali refining pot, control the initial temperature of the crude oil at 25°C, and determine the amount of alkali based on the theoretical alkali amount + excess alkali of 0.15-0.25% of the oil weight. The theoretical alkali amount is determined according to the crude oil Calculate the actual acid value of the oil, the theoretical alkali amount = 7.13×10 -4 × oil weight × acid value, the concentration of lye is 18-20 degrees Baume, and the lye is added within 7-10 minutes to obtain alkali-refined crude oil;

[0035] During the process ...

Embodiment 2

[0049] A preparation method of health-care camellia oil, comprising the following steps:

[0050] (1) Oil extraction: The dried and selected shelled tea seeds are poured into the disc feeder and directly lifted into the oil press; the temperature of the extracted crude oil is 20-30°C, and the crude oil is precipitated by precipitation, and then passed through Filter to obtain cold-pressed crude oil;

[0051] (2) Alkali refining: put the cold-pressed crude oil in an alkali refining pot, control the initial temperature of the crude oil at 25°C, and determine the amount of alkali based on the theoretical alkali amount + excess alkali of 0.15-0.25% of the oil weight. The theoretical alkali amount is determined according to the crude oil Calculate the actual acid value of the oil, the theoretical alkali amount = 7.13×10 -4 × oil weight × acid value, the concentration of lye is 18-20 degrees Baume, and the lye is added within 7-10 minutes to obtain alkali-refined crude oil;

[005...

Embodiment 3

[0066] A preparation method of health-care camellia oil, comprising the following steps:

[0067] (1) Oil extraction: The dried and selected shelled tea seeds are poured into the disc feeder and directly lifted into the oil press; the temperature of the extracted crude oil is 20-30°C, and the crude oil is precipitated by precipitation, and then passed through Filter to obtain cold-pressed crude oil;

[0068] (2) Alkali refining: put the cold-pressed crude oil in an alkali refining pot, control the initial temperature of the crude oil at 25°C, and determine the amount of alkali based on the theoretical alkali amount + excess alkali of 0.15-0.25% of the oil weight. The theoretical alkali amount is determined according to the crude oil Calculate the actual acid value of the oil, the theoretical alkali amount = 7.13×10 -4 × oil weight × acid value, the concentration of lye is 18-20 degrees Baume, and the lye is added within 7-10 minutes to obtain alkali-refined crude oil;

[006...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com