Polyporus umbelatus tea bag and preparation method hereof

A technology for making tea bags and Polyporus oleracea, which is applied in the field of health care products, can solve the problems of poor taste, single nutrient, strong medicinal taste, etc., and achieve the effects of fine taste, strong tea aroma and improved taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

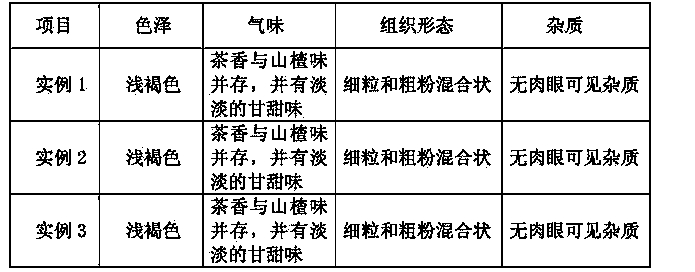

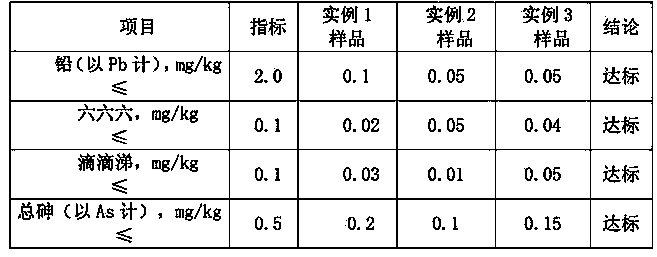

Examples

Embodiment 1

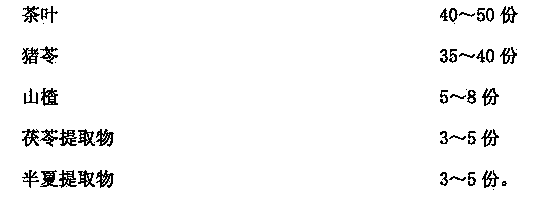

[0025] A polyporus polyporus tea bag is prepared from the following raw materials in parts by mass: 40 parts of tea leaves, 35 parts of polyporus, 5 parts of hawthorn, 3 parts of poria cocos extract, and 3 parts of pinellia extract.

[0026] Wherein, the tealeaves are round-bead type fried green tea; the porcini is fried half-cooked broken particles, and its particle size is 0.8cm; the hawthorn is dried to a water content of 10%, After the seeds are removed, they are crushed into particles with a particle size of 0.5 cm; the Poria cocos extract and pinellia extract are obtained by decocting the original medicinal materials, filtering out the medicinal residues, evaporating and crystallizing the medicinal liquid, and then fully drying and pulverizing. powder.

[0027] Above-mentioned a kind of porcini teabag is prepared by following method, and concrete steps are:

[0028] 1) After the above-mentioned components are processed for the first time, put them into a mixer and mix t...

Embodiment 2

[0034] A Polyporus teabag, in parts by mass, is made from the following raw materials:

[0035] 45 parts of tea leaves, 38 parts of Polyporus, 6.5 parts of Hawthorn, 4 parts of Poria cocos extract, 4 parts of pinellia extract.

[0036] Wherein, the tea leaves are snail-shaped stir-fried green tea; the porcini is fried half-cooked broken particles, and its particle size is 0.8cm; the hawthorn is dried to a water content of 12.5%, except The grains are broken into particles with a particle size of 0.6 cm; the Poria cocos extract and pinellia extract are the powders obtained by decocting the original medicinal materials, filtering out the medicinal residues, evaporating and crystallizing the medicinal liquid, and then fully drying and pulverizing .

[0037] Above-mentioned a kind of porcini teabag is prepared by following method, and concrete steps are:

[0038] 1) After the above-mentioned components are processed for the first time, put them into a mixer and mix them evenly; ...

Embodiment 3

[0044] A Polyporus teabag, in parts by mass, is made from the following raw materials:

[0045] 50 parts of tea leaves, 40 parts of Polyporus, 8 parts of Hawthorn, 5 parts of Poria cocos extract, 5 parts of pinellia extract.

[0046] Wherein, the tea leaves are snail-shaped stir-fried green teas; the porcini is fried half-cooked broken particles with a particle diameter of 1 cm; the hawthorn is dried to a water content of 15%, and the seeds After that, it is crushed into particles with a particle size of 0.8 cm; the Poria cocos extract and Pinellia pinellia extract are powders obtained by decocting the original medicinal materials, filtering out the medicinal residues, evaporating and crystallizing the medicinal liquid, fully drying and pulverizing.

[0047] Above-mentioned a kind of porcini teabag is prepared by following method, and concrete steps are:

[0048] 1) After the above-mentioned components are processed for the first time, put them into a mixer and mix them evenl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com