Method for determining alpha-, beta- and gamma- cellulose contents in dissolving pulp

A technology of cellulose content and dissolving pulp, which is applied in the field of pulp and paper making industry, can solve the problems that the β- and γ-cellulose content of dissolving pulp cannot be measured, and achieve the effect of fast measurement speed, high accuracy and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

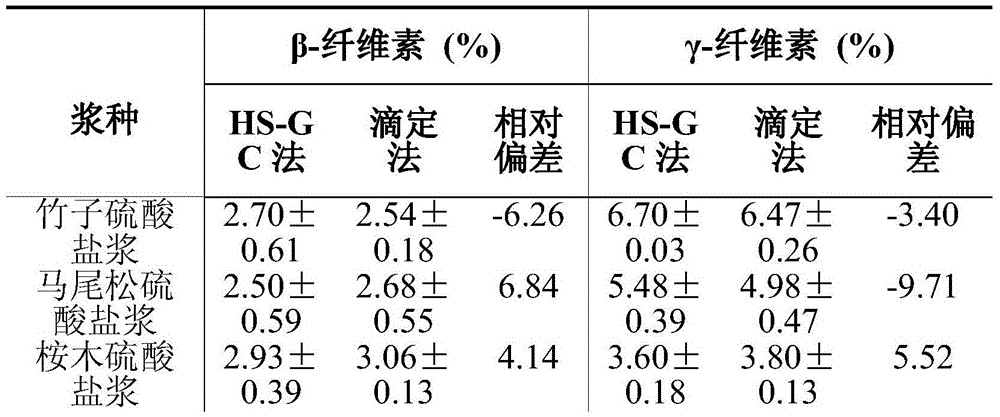

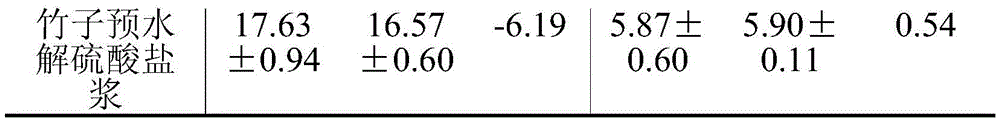

Examples

Embodiment

[0030] (1) Sample pretreatment: Take two 2.0±0.05g (accurate to 1mg) samples to be tested and put them into two 150-mL beakers respectively, and add 20mL of 9.45% w / w to the beakers respectively and 17.5% w / w sodium hydroxide solution, then put the beaker into a constant temperature water bath (25±0.5°C), and repeatedly dip the sample with a flat glass rod. Then add 80 mL of sodium hydroxide solution with the same concentration as before to each beaker, and stir it. Finally, cover the beaker with a watch glass, and record the time from the first addition of sodium hydroxide to the end of the reaction process (also called mercerization process). After the reaction is over, take out the beaker, filter with a washed and air-dried glass filter and a suction filter flask, and collect the filtrate in a glass bottle with a cover.

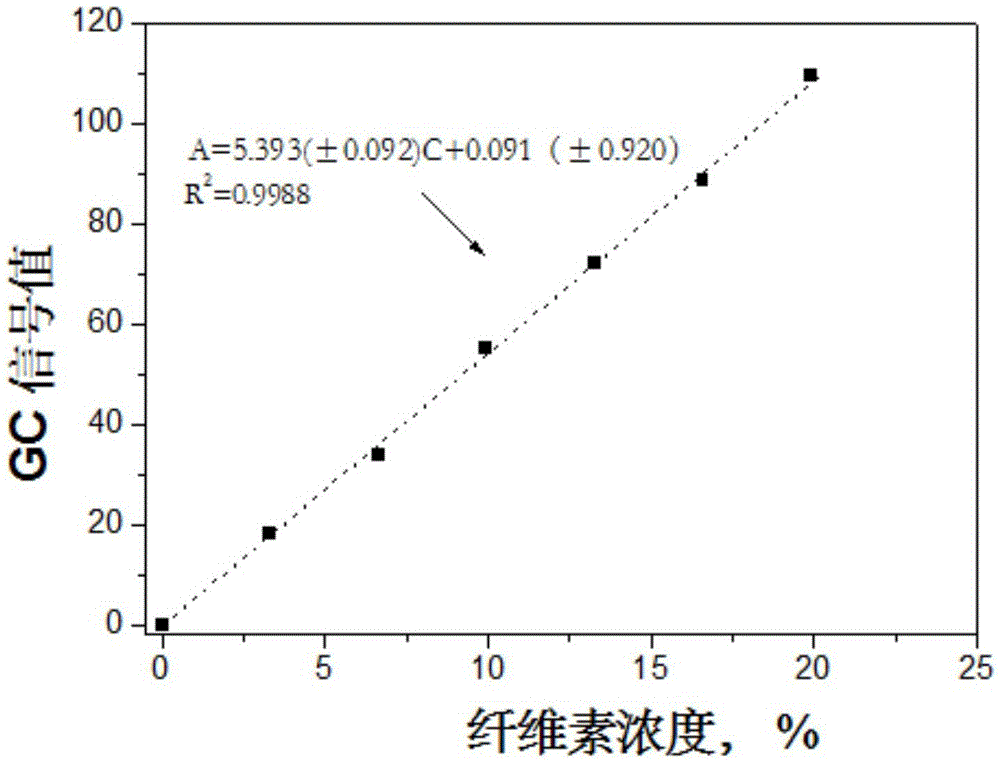

[0031]Take 0.2mL of the filtrates obtained after mercerization of lye with different concentrations and add them to two headspace bottles respectively, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com