Fusion tapered optical fiber power beam combiner and manufacturing method thereof

A technology of a beam combiner and an optical fiber bundle, which is applied to the melting point taper type optical fiber power beam combiner and its production field, can solve the problems that the optical fiber High power output, guaranteed coupling efficiency, high brightness signal laser beam combining effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

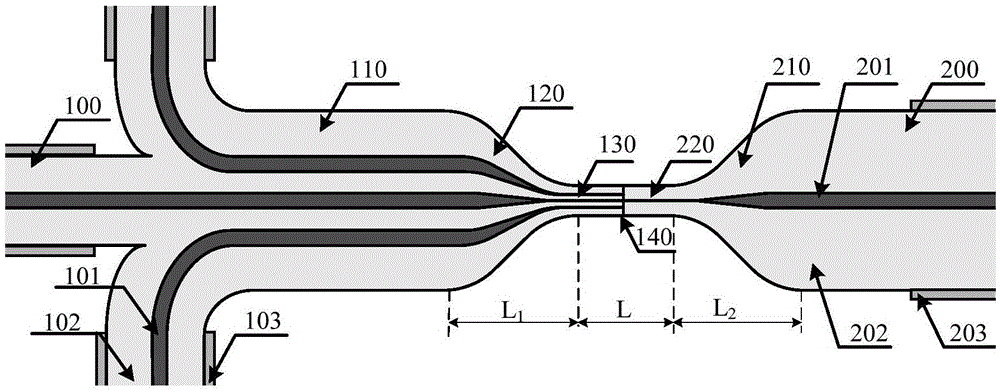

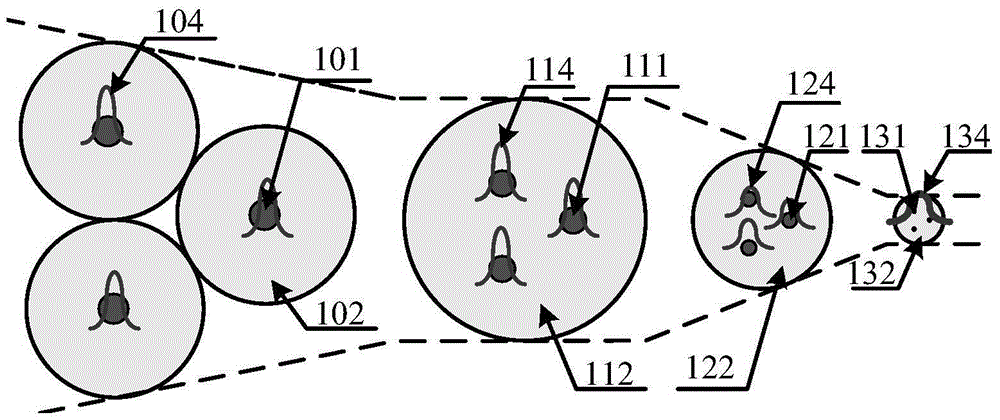

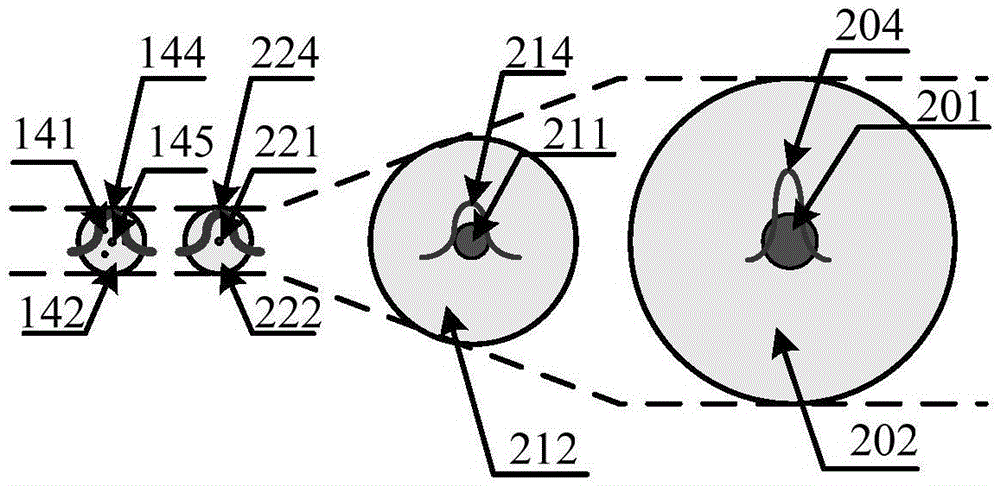

[0038] Figure 1 to Figure 3 It is an implementation process of making a 3×1 melting point tapered optical fiber power combiner by directly combining tapered tapes. During the manufacturing process, firstly, 4 cm of the middle coating layer 103 (including the outer cladding) of the three double-clad signal optical fibers 100 with core / inner cladding diameters of 15 / 130 μm were removed to expose the inner cladding 102 . Use two optical fiber clamps to hold the optical fibers on both sides of the three optical fibers with the coating layer, and then twist them one or two times in the opposite radial direction to make the three optical fibers closely fit in the area where the coating layer is stripped together, such as figure 2 The structure on the left is shown. Then put the bundled fiber bundles on the fiber optic tapering machine, use the flame to heat the stripped coating area to make them fuse with each other, and at the same time apply a pulling force in the opposite dir...

Embodiment 2

[0040] Figure 5 to Figure 6 It is the implementation process of making a 7×1 melting point tapered optical fiber power combiner by means of low refractive index glass tube grouping. During the manufacturing process, firstly, the coating layer 103 (including the outer cladding) at one end of seven double-clad signal optical fibers 100 with core / inner cladding diameters of 20 / 130 μm was removed by 4 cm to expose the inner cladding 102 . At the same time, two low-refractive index glass tubes 300 with a length of 10 cm (numerical aperture NA=0.22, inner diameter / outer diameter 800 / 1000 μm) were tapered to 400 / 500 μm in the middle section, so that the length of the cone waist was 2 cm. Then the inner claddings of the processed seven optical fibers are inserted into the low-refractive-index glass tube, so that the inner claddings are closely arranged in the tapered waist area 300 of the glass tube, such as Image 6 The structure on the left is shown. Then place the glass tube 300...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com