EUV light source and exposure device

A technology of light source and optical axis, applied in the field of EUV light source and exposure device, can solve the problems of inability to meet production requirements, low power of extreme ultraviolet light, etc., and achieve the effect of increasing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

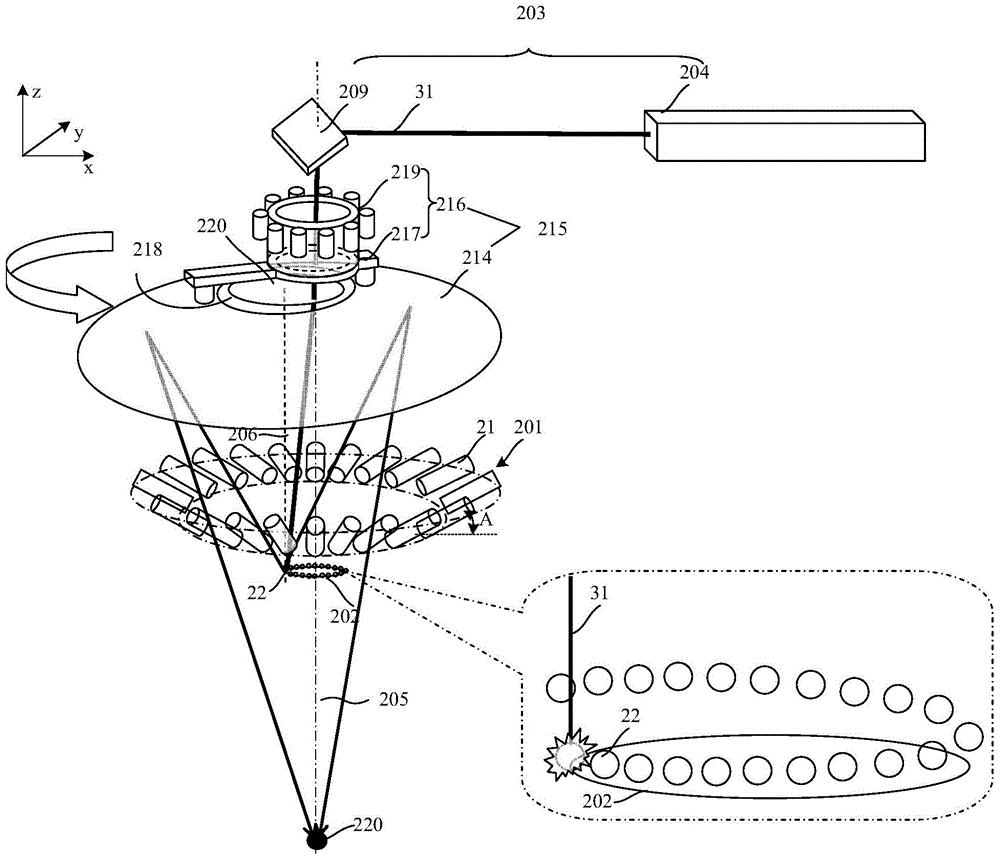

[0036] As mentioned in the background art, the power of the extreme ultraviolet light generated by the existing extreme ultraviolet light source is still small (about 10-30W), and in the actual lithography process, the power of the light source needs to reach 250W. The extreme ultraviolet light source produced by the extreme ultraviolet light source cannot meet the requirements of actual production.

[0037]The study found that the tin droplet nozzle of the existing extreme ultraviolet light source controls the spraying of tin droplets in a mechanical way, so that adjacent tin droplets are separated in space, and the laser beam can bombard each tin droplet. Each tin drop forms plasma when it is bombarded, and the plasma radiation produces extreme ultraviolet light. If the distance between two tin drops is too close or the two tin drops stick together, when the laser beam is bombarding the current tin drop, a The plasma debris will affect the next drop of tin, resulting in poor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com