Schottky diode and manufacturing method thereof

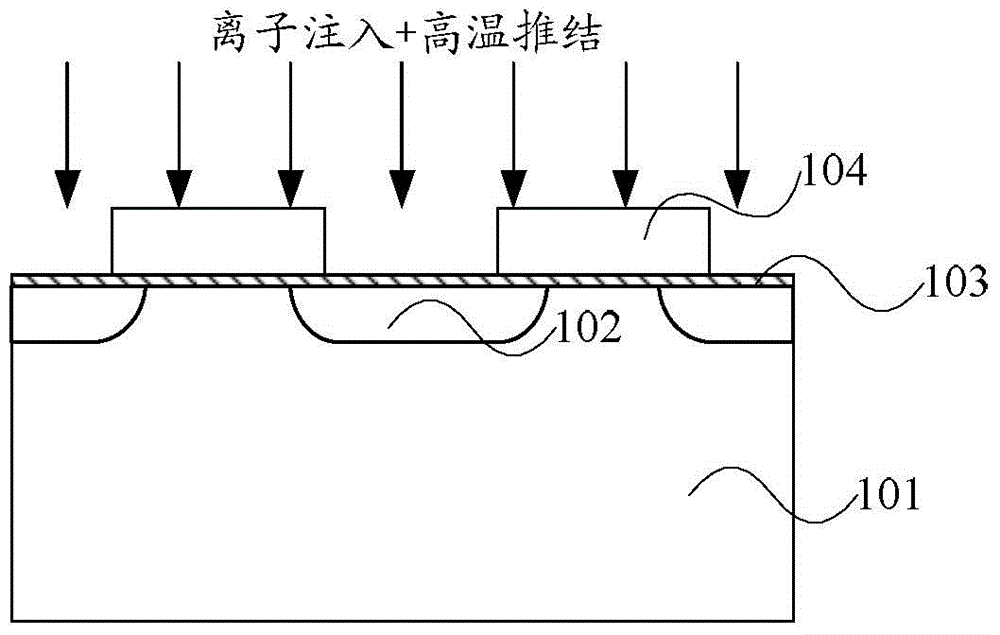

A technology of Schottky diode and fabrication method, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of inaccurate size control at the widest point of P well, decreased device stability, and inability to reduce VF, etc. , to achieve the effect of omitting the high temperature push junction process, reducing the VF, and enhancing the electron capture ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The Schottky diode provided by the present invention and its manufacturing method will be described in more detail below with reference to the drawings and embodiments.

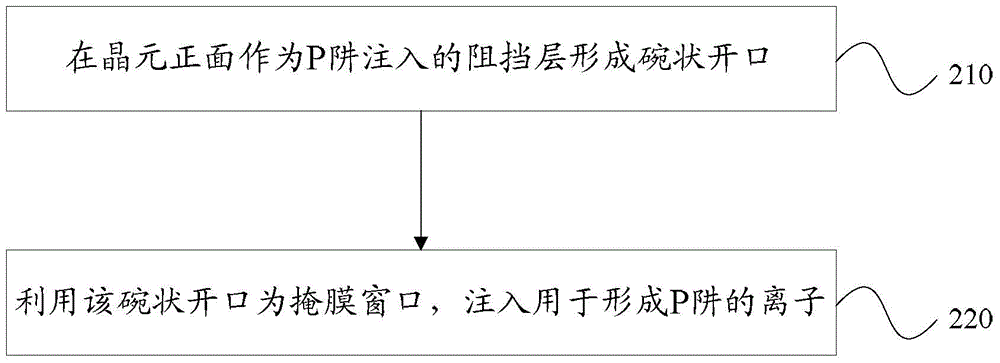

[0049] Embodiments of the present invention, such as figure 2 As shown, the manufacturing method of the Schottky diode at least includes the following steps:

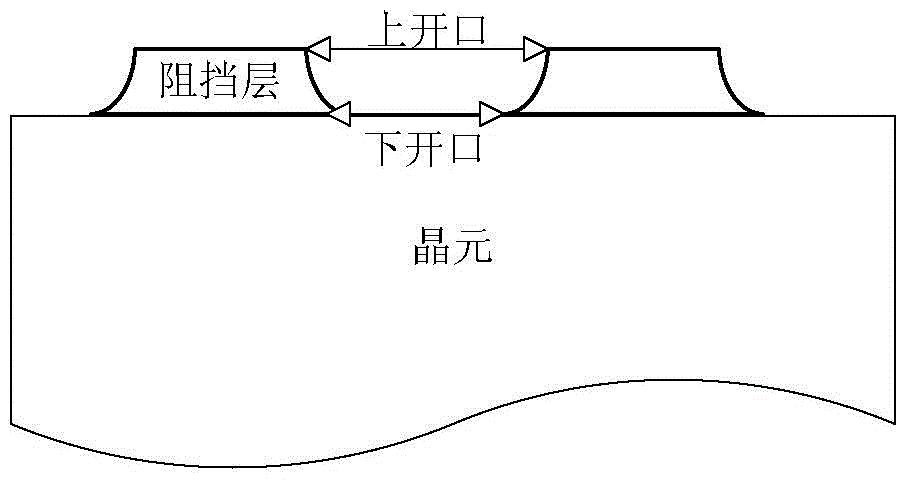

[0050] Step 210: forming a bowl-shaped opening on the front side of the wafer as a barrier layer implanted into the P well;

[0051] Among them, the wafer is the carrier for making Schottky diodes. The front side of the die refers to the side that is used to form the Schottky diode.

[0052] Step 220 : using the bowl-shaped opening as a mask window, injecting ions for forming a P well.

[0053] In the embodiment of the present invention, the self-alignment method of the bowl-shaped opening is used to inject ions for forming the P well. Because the mask window used as the P-well ion implantation is a bowl-shaped opening, the P-well can be fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com