Disc type motor of integral cooling heat radiation structure

A disc motor, heat dissipation structure technology, applied in the shape/pattern/structure of winding conductor, magnetic circuit shape/pattern/structure, electrical components, etc., can solve the problem of poor thermal conductivity of motor, low power density and efficiency, shaft To solve the problems of large installation size, etc., to achieve the effect of improving convective heat transfer capacity, improving power density, and high temperature rise resistance level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings.

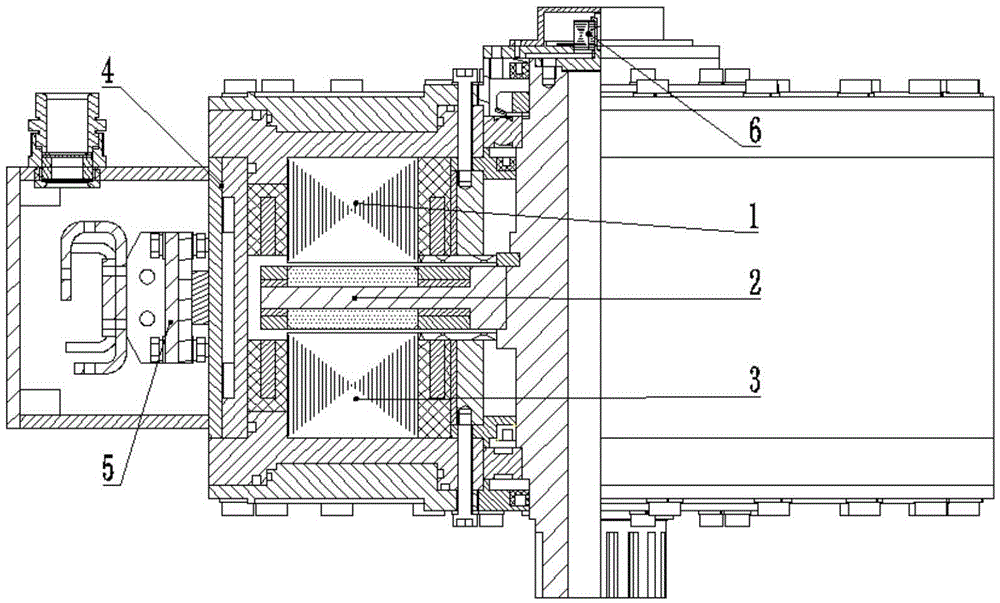

[0026] Such as figure 1 As shown, the disc motor with an integrated cooling and heat dissipation structure is an axial flux motor, which adopts a double-stator single-rotor structure, including a casing assembly 4, and the rotor assembly 2 connects the non-drive end stator assembly 1 and the non-drive end stator assembly 1 through set screws The driving end stator assembly 3 is fixed on the casing assembly 4, the rotor assembly 2 is located in the middle of the non-driving end stator assembly 1 and the driving end stator assembly 3, and the resolver assembly 6 is fixed on the non-driving end stator assembly 1 by set screws, The outlet box assembly 5 is directly welded to the casing assembly 4 .

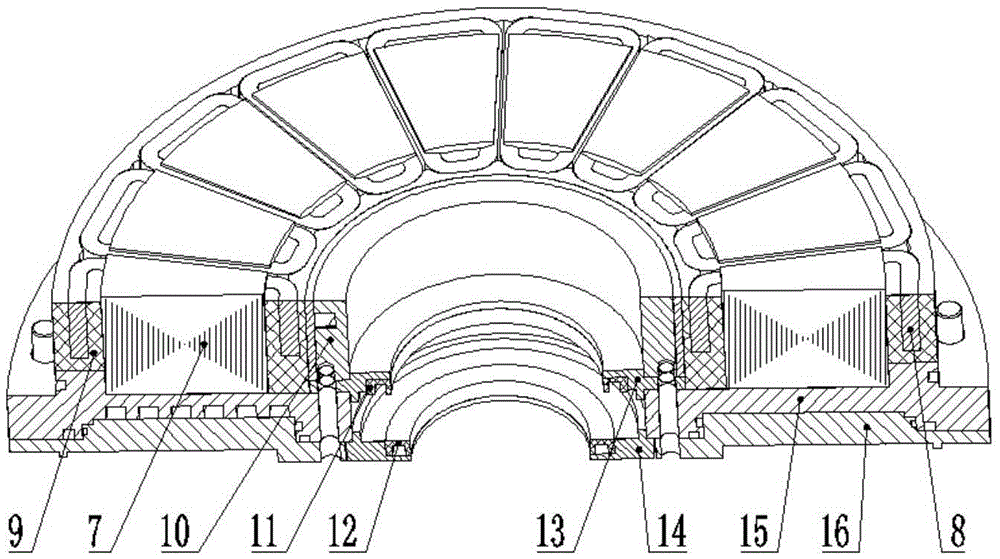

[0027] Such as figure 2 As shown, the drive end stator assembly 3 includes a stator core 7, the stator core 7 is wound from a high magnetic permeability, low loss, ultra-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com