Production method of paste fermented bean curds

A production method and technology of fermented bean curd, which is applied in the field of fermented bean curd with sauce, can solve the problems of over-salty taste and long fermentation time, and achieve the effects of improving taste, reducing the amount of salt, and shortening the fermentation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

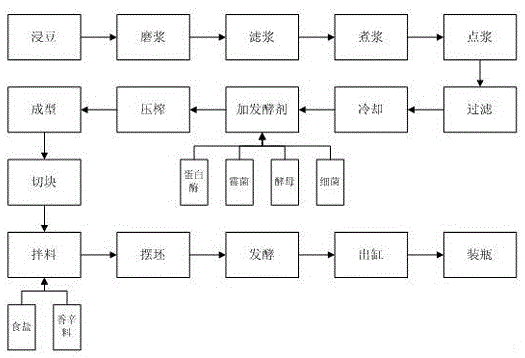

Image

Examples

Embodiment 1

[0032] The production method of fermented bean curd with soy sauce, the technological steps are as follows: soaking beans, grinding and filtering pulp, boiling pulp, ordering pulp, filtering, cooling, adding starter, forming, pressing, cutting into pieces, mixing materials, and fermenting in tanks. The specific steps are the same as the traditional process in the previous embodiment.

[0033] Only add leavening agent in the bean curd brain after cooling, make wherein the content of protease reaches 20,000 units / kg, and the total content of Mucor, Aspergillus and Rhizopus reaches 10 6 CFU / g, the total content of Hansenula, Luxie and Torulopsis reached 10 6 CFU / g, the total content of micrococci, cocci and bacilli reaches 10 6 CFU / g, then add salt, the amount of salt added is 10g per 100g of bean dregs, after the bean dregs are fermented in the tank for 6 months, the free amino nitrogen content is 0.7g / 100g, and the water-soluble protein The content reaches 5.5g / 100g, and the ...

Embodiment 2

[0035] The production method of fermented bean curd with soy sauce, the technological steps are as follows: soaking beans, grinding and filtering pulp, boiling pulp, ordering pulp, filtering, cooling, adding starter, forming, pressing, cutting into pieces, mixing materials, and fermenting in tanks. The specific steps are the same as the previous embodiment.

[0036] Only add fermentation agent in the tofu brain after cooling, make wherein the total content of protease reaches 30,000 units / kg, and the total content of Mucor and Rhizopus reaches 2×10 6 CFU / g, the total content of film-forming yeast, Candida and Pichia reached 2×10 6 CFU / g, the total content of cocci and bacilli reaches 2×10 6 CFU / g, then add salt, the amount of salt added is 8g per 100g of bean dregs. After making the bean dregs and fermenting them in tanks for 4 months, the content of free amino nitrogen was determined to be 0.73g / 100g, the content of water-soluble protein reached 5.7g / 100g, and the content o...

Embodiment 3

[0040] The production method of the fermented bean curd with soy sauce, the process steps are as follows: soaking beans, grinding and filtering, boiling, pointing, filtering, forming, pressing, cutting into pieces, adding starter, mixing materials, and fermenting in tanks. The specific steps are the same as the previous embodiment.

[0041] Only add starter to the bean block, so that the content of protease reaches 30,000 units / kg, and the total content of Mucor, Aspergillus and Rhizopus reaches 2×10 6 CFU / g, the total content of Hansenula, Candida and Pichia reached 2×10 6 CFU / g, the total content of micrococci, cocci and bacilli reaches 2×10 6 CFU / g, then add salt, the amount of salt added is 12g per 100g of bean dregs. After 10 months of fermentation in the tank, the content of free amino nitrogen was 0.76g / 100g, the content of water-soluble protein reached 6.0g / 100g, and the content of sodium chloride was 11.8g / 100g. The sensory evaluation was in line with and better tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com