Liquid stabilizer and its application for treating waste incineration fly ash with high lead and cadmium content

A technology of waste incineration fly ash and liquid stabilizer, applied in the field of heavy metal pollution treatment, can solve the problems of high cost, long construction time, large amount of addition, etc., and achieve the effects of low cost, convenient construction and high effective utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

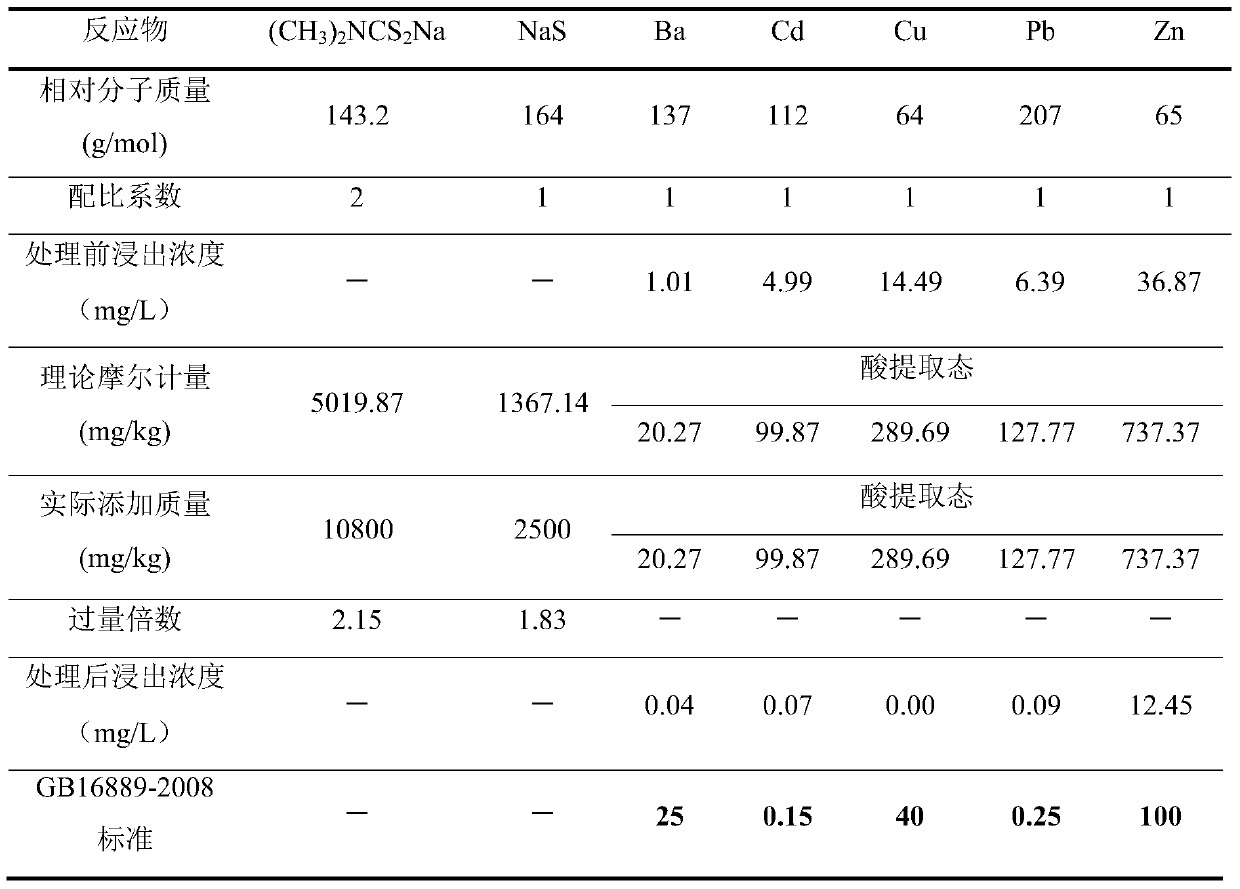

[0016] Example 1: A waste incineration fly ash project in a certain area of Chongqing, after determining the treatment target, the fly ash meets the requirements of the "Landfill Pollution Control Standard for Domestic Waste" (GB16889-2008). Fly ash samples were collected on site, and the total content of heavy metals was 4758.6mg / kg. The leaching solution prepared according to "Solid Waste Leaching Toxicity Leaching Method Acetic Acid Buffer Solution Method" (HJ / T300-2007), the concentration of lead is 6.39mg / L, cadmium The concentration is 4.99mg / L, which exceeds the GB16889-2008 standard, and other heavy metals do not exceed the standard. Stabilize the waste incineration fly ash, weigh 100g of fly ash, and add a stabilizer with a mass ratio of 5% (ie 5g) to it. The components and ratio of the stabilizer are, by weight, 1 part of dimethyl Sodium dithiocarbamate 1.08g, 0.23 part sodium sulfide 0.25g, 0.23 part sodium silicate 0.25g, 0.1 part sodium lignosulfonate 0.11g, 3.1 ...

Embodiment 2

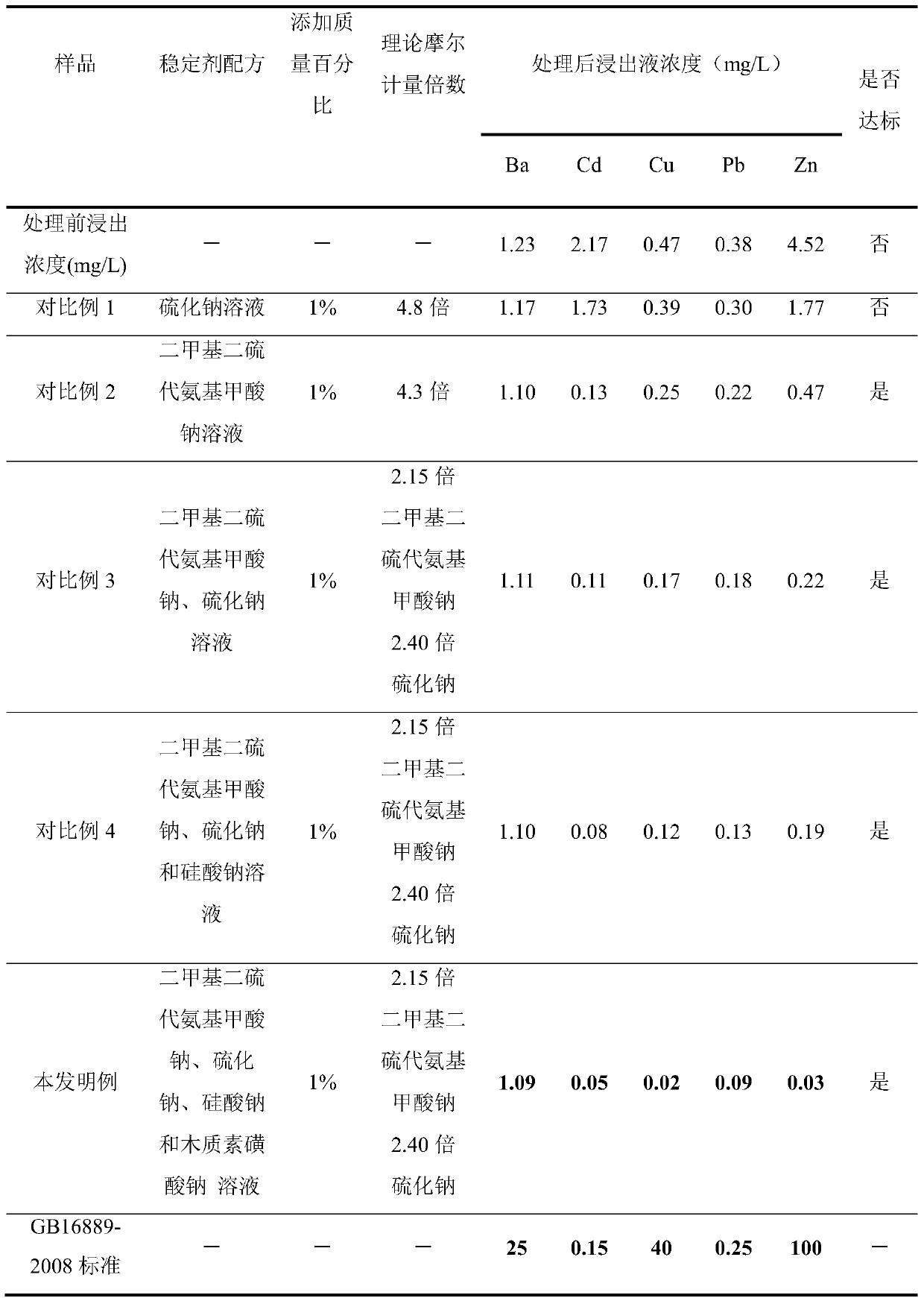

[0028] Example 2: In a waste incineration fly ash project in Chengdu, the treatment target is determined to be that the treated fly ash meets the requirements of the "Landfill Pollution Control Standard for Domestic Waste" (GB16889-2008). Fly ash samples were collected on site. The total content of heavy metals was 175.28mg / kg. The concentration of lead in the leachate prepared according to the "Solid Waste Leaching Toxicity Leaching Method Acetic Acid Buffer Solution Method" (HJ / T300-2007) was 0.38mg / L, The concentration is 2.17mg / L, the concentrations of lead and cadmium both exceed the GB16889-2008 standard, and other heavy metals do not exceed the standard. The waste incineration fly ash was stabilized, and three different formulations of stabilizers were used to compare the stabilization effects of the lead and cadmium fly ash.

[0029] (1) Comparative Example 1. Weigh 1 part of 100g Chengdu fly ash, and add a sodium sulfide solution with a mass ratio of 1% (ie 1 g) of fly a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com