Sulfur-tolerant methanation catalyst and preparation method thereof

A sulfur-resistant methanation and catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, and hydrocarbon production from carbon oxides, can solve problems such as poor selectivity and low CO conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

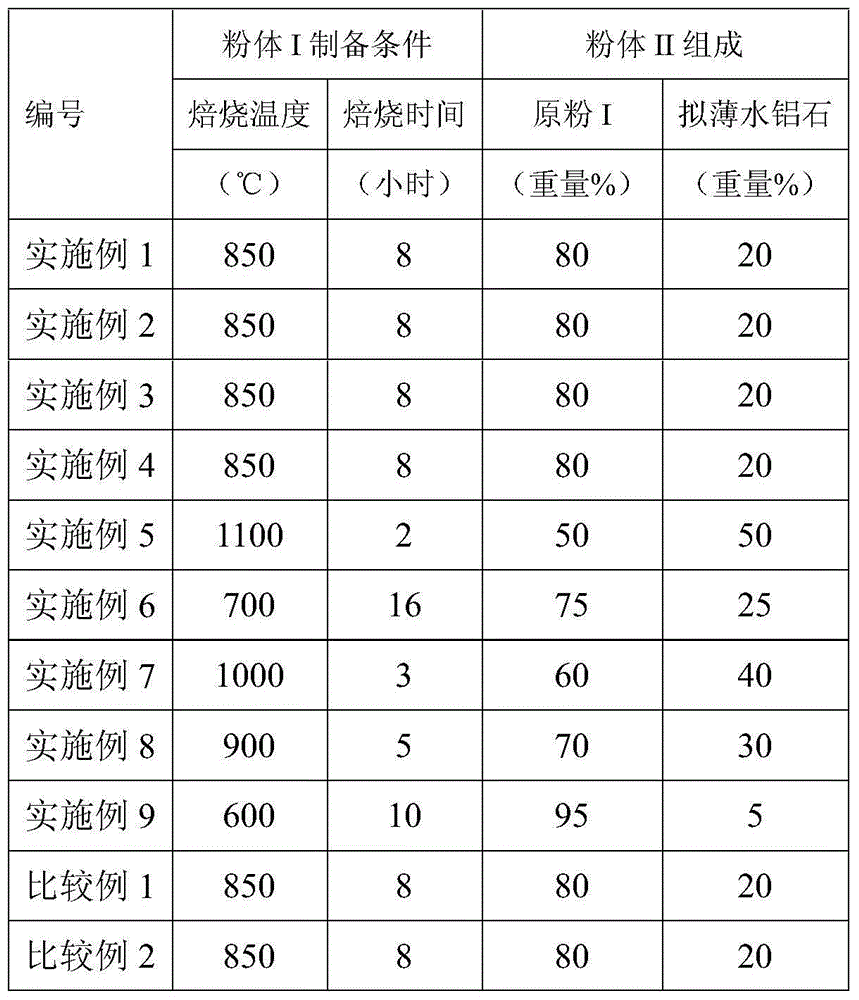

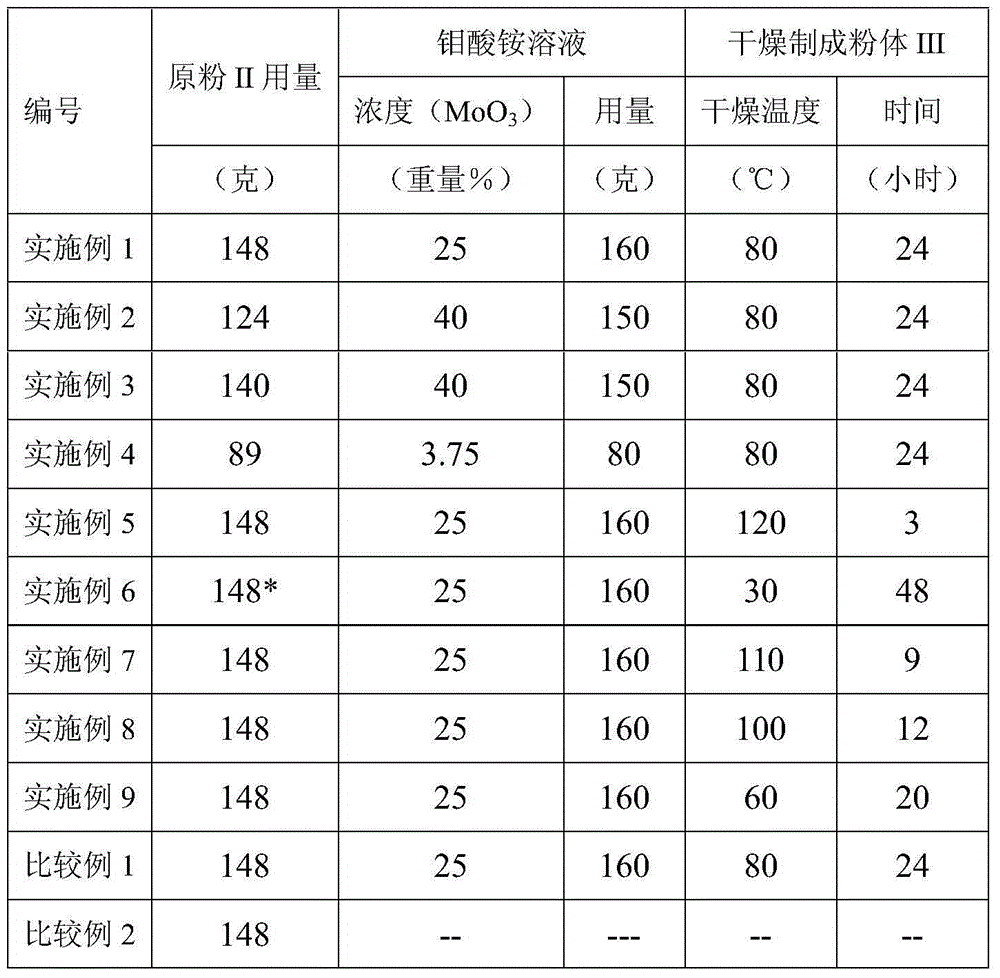

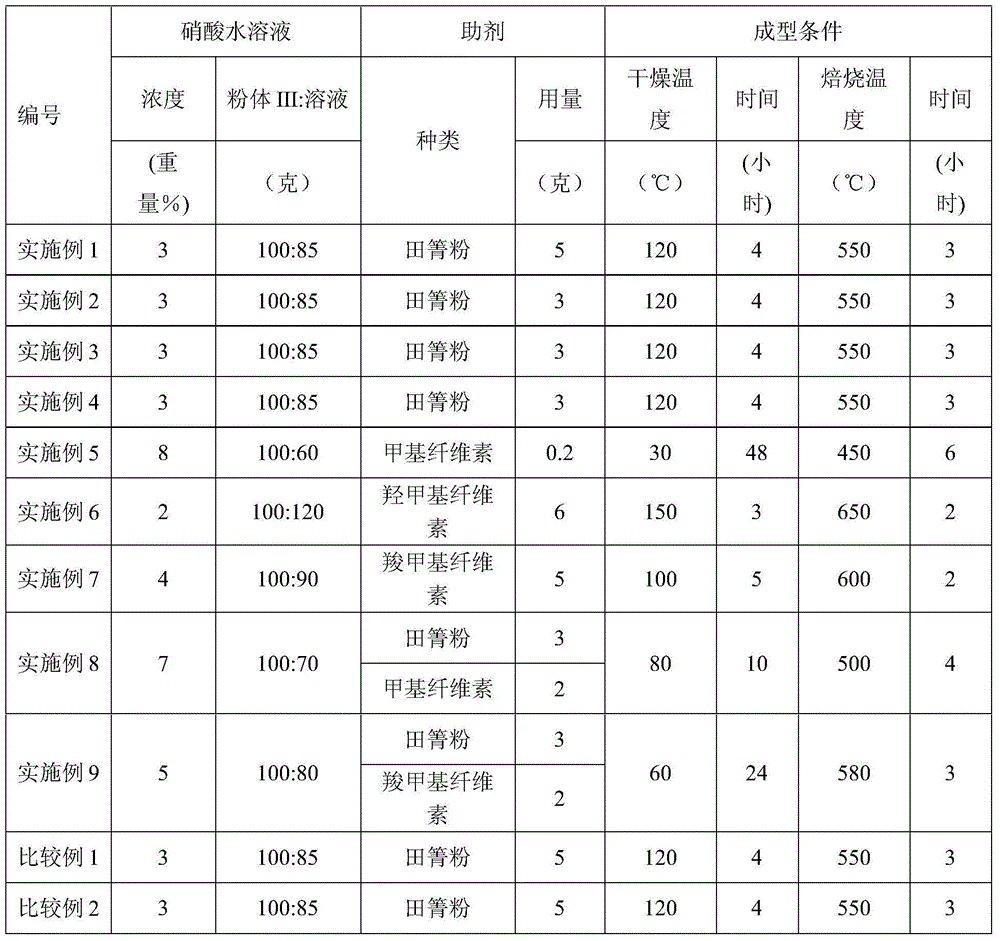

Embodiment 1

[0054] Weigh 300 grams of pseudo-boehmite raw powder and roast at 850°C for 8 hours to obtain powder I; weigh 160 grams of the above-mentioned powder I and pseudo-boehmite powder in a weight percentage of 80:20 to obtain powder Body II; Weigh 148 grams of powder II, add MoO in weight percentage 3 Mix 160 grams of 25.0% ammonium molybdate solution, dry and dehydrate at 80°C for 24 hours, and remake powder III; the above powder III and the aqueous solution containing 3% nitric acid in weight percentage are 100:85 by weight , adding 5 grams of Tianqing powder, kneading and extruding, drying at 120°C for 4 hours, and roasting at 550°C for 3 hours to obtain catalyst precursor I; weigh 94 grams of catalyst precursor I and the content of Ni contained in weight percent 2 P is that 100 grams of the acidic aqueous solution of nickel hypophosphite and ammonium hypophosphite of 6% are impregnated, wherein the mol ratio of nickel hypophosphite and ammonium hypophosphite in the acidic aqueo...

Embodiment 2

[0061] Weigh 300 grams of pseudo-boehmite powder and roast at 850°C for 8 hours to obtain powder I; weigh 160 grams of the above-mentioned powder I and pseudo-boehmite powder in a weight percentage of 80:20 to obtain Original powder II; Weigh 124 grams of original powder II, add MoO in weight percentage 3 Mix 150 grams of 40.0% ammonium molybdate solution, dry and dehydrate at 80°C for 24 hours, and remake powder III; the above powder III and the aqueous solution containing 3% nitric acid in weight percentage are 100:85 by weight , adding 3 grams of Tianqing powder, kneading and extruding, drying at 120°C for 4 hours, and roasting at 550°C for 3 hours to obtain catalyst precursor I; weigh 92 grams of catalyst precursor I and the Ni-containing 2 The acidic aqueous solution of nickel hypophosphite and ammonium hypophosphite with P being 8% is impregnated in equal volume, wherein the molar ratio of nickel hypophosphite and ammonium hypophosphite in the acidic aqueous solution is ...

Embodiment 3

[0065] Weigh 300 grams of pseudo-boehmite powder and roast at 850°C for 8 hours to obtain powder I; weigh 160 grams of the above-mentioned powder I and pseudo-boehmite powder in a weight percentage of 80:20 to obtain Raw powder II; Weigh 140 grams of raw powder II, add MoO in weight percentage 3 Mix 150 grams of 40.0% ammonium molybdate solution, dry and dehydrate at 80°C for 24 hours, and remake powder III; the above powder III and the aqueous solution containing 3% nitric acid in weight percentage are 100:85 by weight , adding 3 grams of Tianqing powder, kneading and extrusion molding, drying at 120°C for 4 hours, and roasting at 550°C for 3 hours to obtain catalyst precursor I; weigh 100 grams of catalyst precursor I and 2 The acidic aqueous solution of nickel hypophosphite and ammonium hypophosphite with P being 0.1% is impregnated in equal volume, wherein the molar ratio of nickel hypophosphite and ammonium hypophosphite in the acidic aqueous solution is 1:0.83, and the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com