Airtight feeding and discharging device for volatile media and use method thereof

A technology of feeding and discharging materials and media, which is applied in the direction of liquid flow control devices, distribution devices, special distribution devices, etc., can solve problems of economy and reliability, cannot adapt to environmental protection requirements, and unstable use effects, etc., to achieve Remarkable environmental protection effect, sensitive opening and contraction, and the effect of reducing the emission of medium steam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

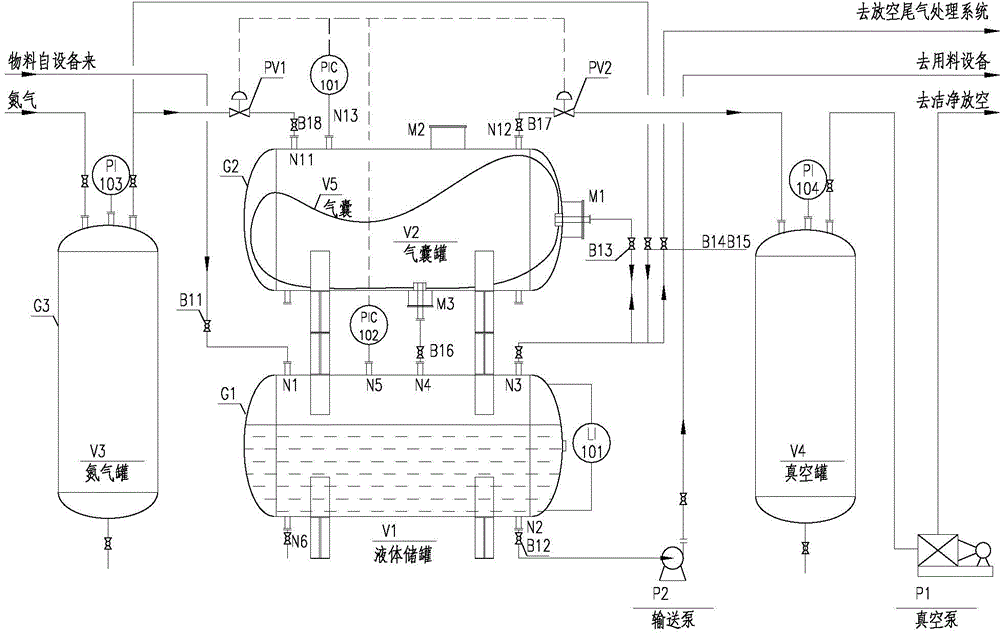

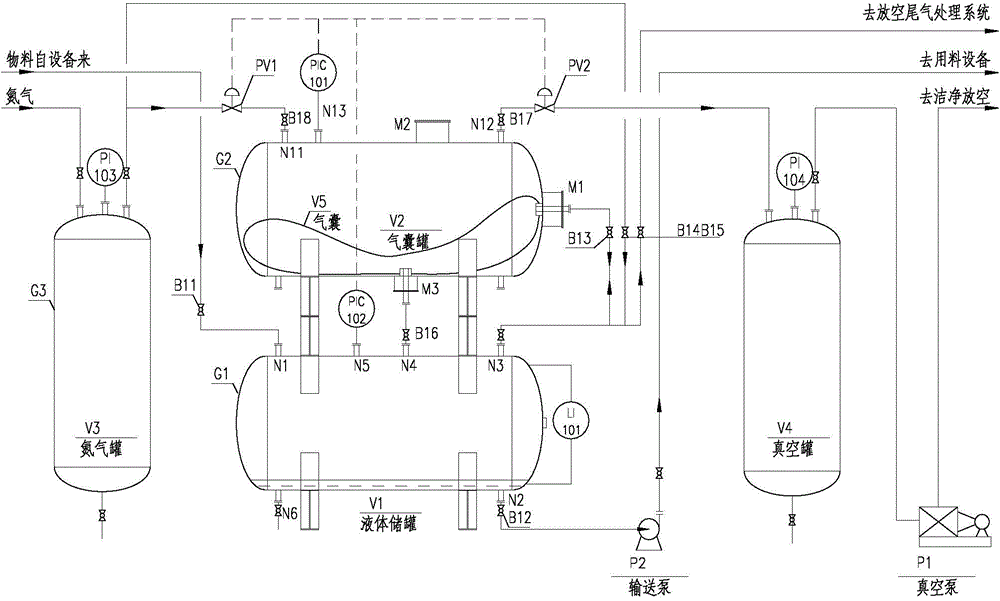

[0053] A hexane liquid storage device composed of a liquid tank V1 (hexane storage tank), an air bag tank V2, a nitrogen tank V3, a vacuum tank V4, a vacuum pump P2, a delivery pump P1 and a control pipeline.

[0054] The liquid tank V1 is a horizontal elliptical head, the inner diameter of the equipment is 1800mm, the length of the cylinder is 4200mm, and the total volume is 12M 3 ;The air bag tank V2 is a horizontal elliptical head, the inner diameter of the equipment is 1800mm, the length of the cylinder is 4200mm, and the total volume is 12M 3 , with a built-in soft airbag, the size of the airbag is 1600mm in inner diameter, 3800mm in cylinder length, and the contraction interface is 200mm.

[0055] Nitrogen tank V3 and vacuum tank V4 are both vertical oval head storage tanks with a volume of 2M 3 . The vacuum pump P2 is a rotary vane vacuum pump with a pumping capacity of 15L / min, and the transfer pump P1 is a centrifugal chemical process pump with a flow rate of 12.5...

Embodiment 2

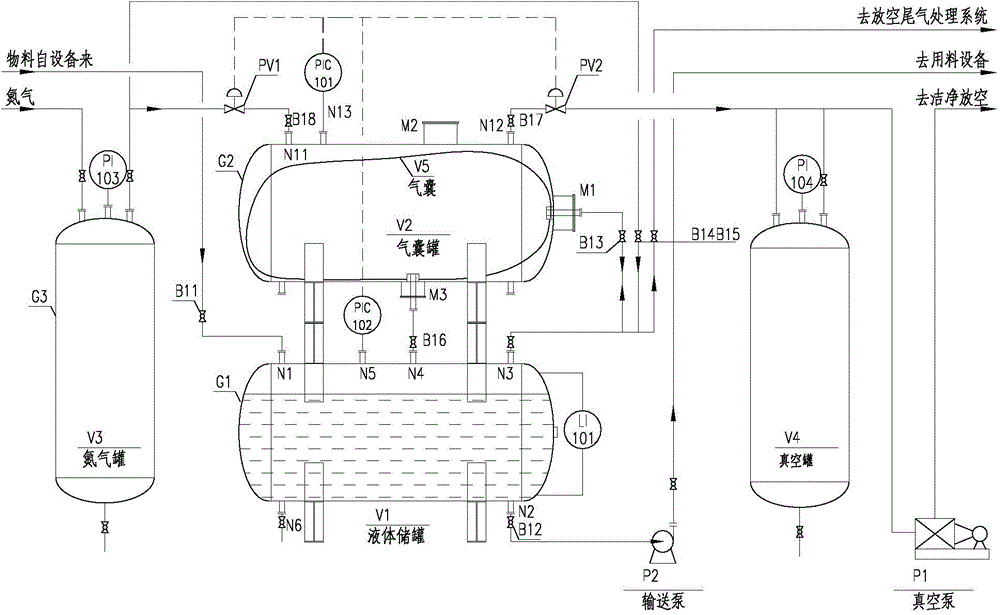

[0073] A toluene liquid storage device composed of a liquid tank V1 (toluene storage tank), an airbag tank V2, a nitrogen tank V3, a vacuum tank V4, a vacuum pump, a delivery pump and a control pipeline.

[0074] Toluene liquid tank V1 is a horizontal elliptical head, the inner diameter of the equipment is 1800mm, the length of the cylinder is 4200mm, and the total volume is 12M 3 ;The air bag tank V2 is a horizontal elliptical head, the inner diameter of the equipment is 1800mm, the length of the cylinder is 4200mm, and the total volume is 12M 3 , built-in customized soft airbag (airbag size is 1600mm inner diameter, cylinder length 3800mm, contraction interface is 200mm.

[0075] Nitrogen tank V3 and vacuum tank V4 are both vertical oval head storage tanks with a volume of 2.0M 3 . The vacuum pump P1 is a rotary vane vacuum pump with a pumping capacity of 15L / min, and the delivery pump P2 is a centrifugal chemical process pump with a flow rate of 12.5M 3 / hr, head is 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com