Circulating cooling water ozone bypass-flow treatment system and method

A circulating cooling water and flow treatment technology, which is applied in natural water treatment, water/sewage treatment, non-polluted water treatment, etc., can solve the problems of corrosion and scaling of circulating cooling water, achieve enhanced sterilization and algae reduction, delay equipment corrosion, Simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

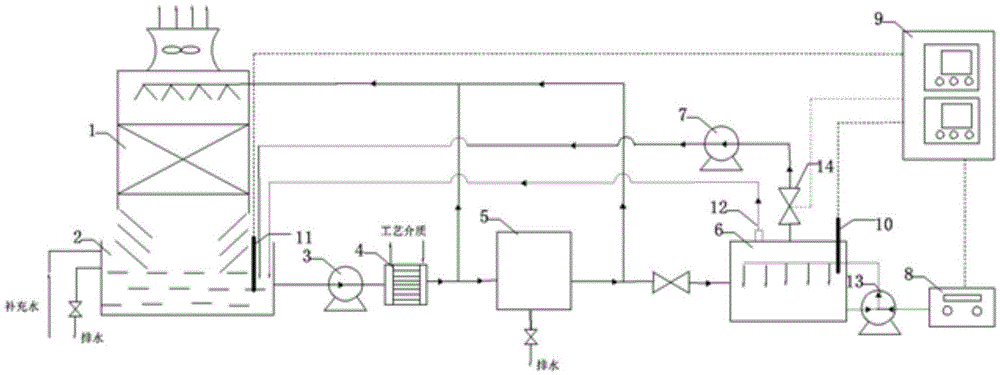

[0028] This embodiment discloses a circulating cooling water ozone bypass treatment system, which can improve the ozone water treatment effect, reduce the equipment investment and operation cost of the ozone water treatment process, and effectively solve the equipment corrosion problem caused by excessive residual ozone in the system.

[0029] Specifically, the circulating cooling water ozone bypass treatment system such as figure 1 As shown, an ozone bypass water treatment system is added to the original cooling tower system, and the cooling tower system includes a sequentially connected cooling tower 1, reservoir 2, first circulation pump 3, heat exchanger 4 and filter tank 5 , the filtrate outlet of the filter pool 5 communicates with the circulating cooling water inlet of the cooling tower 1, and the outlet of the heat exchanger 4 also communicates with the circulating cooling water inlet of the cooling tower 1.

[0030]The ozone bypass water treatment system comprises an ...

Embodiment 2

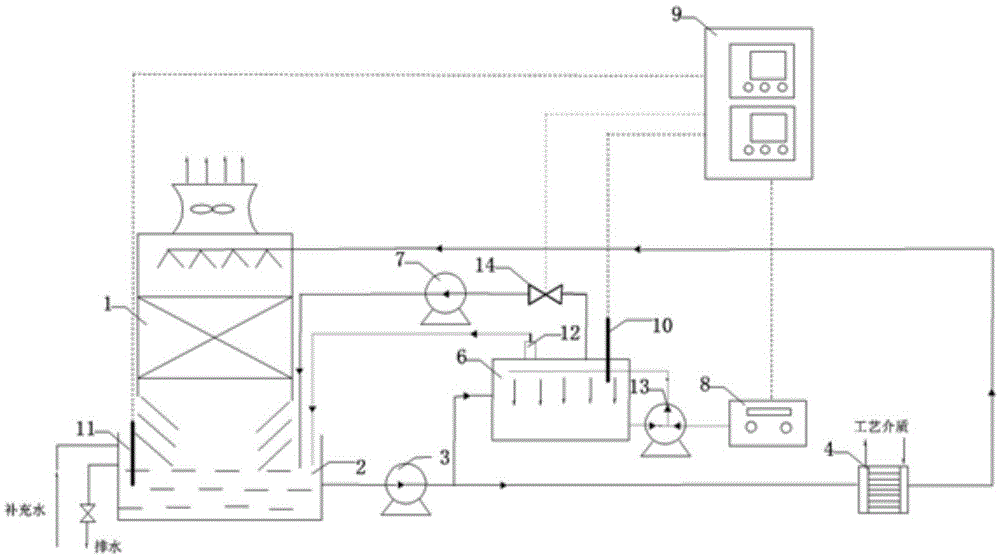

[0038] This embodiment discloses another implementation method of a circulating cooling water ozone bypass treatment system, specifically, the circulating cooling water ozone bypass treatment system such as figure 2 As shown, an ozone bypass water treatment system is added in the original cooling tower system, and the cooling tower system includes a cooling tower 1, a reservoir 2, a first circulation pump 3 and a heat exchanger 4, and the circulation of the cooling tower 1 The cooling water outlet is communicated with the reservoir 2, and the first circulating pump 3 and the heat exchanger 4 are arranged on the pipeline communicating between the reservoir 2 and the cooling water inlet of the cooling tower 1; the ozone bypass water treatment system includes an ozone reaction Tower 6, ozone generator 8, control device 9, first ORP sensor probe 11, second ORP sensor probe 10, second circulation pump 7, gas-liquid mixing pump 13 and electric control valve 14, described ozone react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com