Secondary sludge thermal hydrolysis treatment method and device

A technology of treatment device and treatment method, which is applied in the direction of pyrolysis treatment of sludge, vaporization of by-products, etc., can solve the problems of difficult separation and hydrolysis of organic matter and bound water, and difficulty in excessive sludge increase, so as to save steam exhaust time and production. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

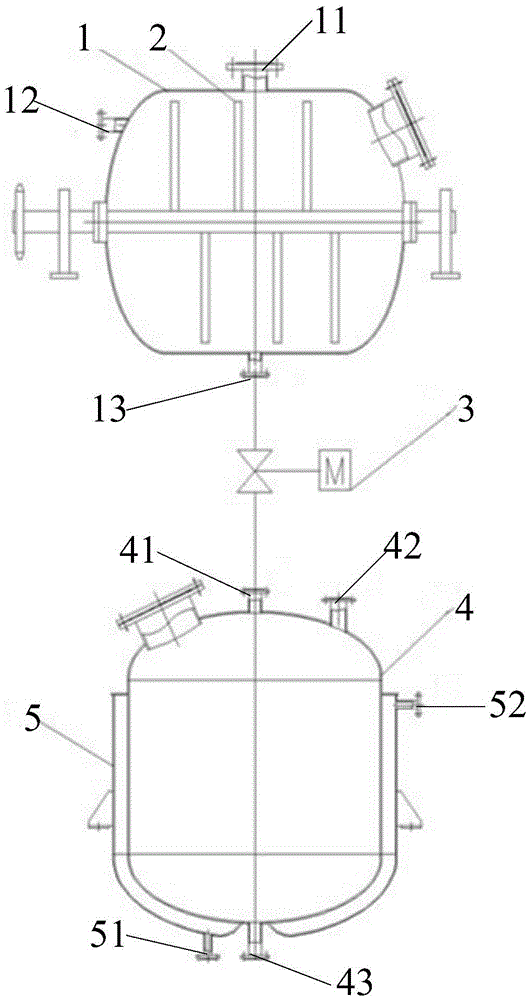

[0018] The invention discloses a sludge secondary thermal hydrolysis treatment method, which comprises the following steps:

[0019] The first step: the sludge is injected into the first-stage sludge pyrolysis tank and stirred with steam. The sludge undergoes a first-stage thermal hydrolysis reaction and becomes a pyrolysis mud. The organic matter in the sludge is initially decomposed and discharged into the second-stage Slurry pyrolysis tank, the process conditions are: inject 1.0Mpa-2.0Mpa saturated steam into the first-level sludge pyrolysis tank, the temperature is 150-200°C, and the first-level thermal hydrolysis reaction time is 25-30 minutes;

[0020] Step 2: Add quicklime agent in advance to the secondary mud pyrolysis tank, and the pyrolysis mud will further pyrolyze the organic matter that is not easily hydrolyzed under the action of calcium hydroxide. The reaction time of the secondary thermal hydrolysis is 15-20 minutes;

[0021] Step 3: Cool the pyrolysis mud to n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com