CS carbon fiber silicon fireproof insulation board and manufacturing method thereof

A technology of fire-proof insulation board and carbon fiber, which is applied in the direction of heat preservation, ceramic products, and other household appliances, etc., can solve the problems of not being able to achieve fireproof performance, and achieve the effect of good insulation effect and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

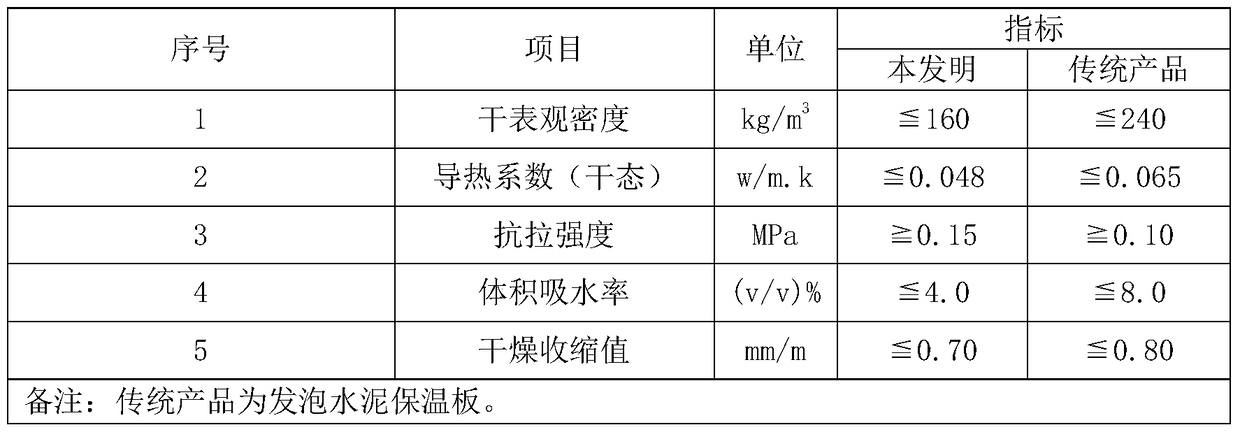

[0032] Embodiment 1: Portland cement, slag, foaming agent, foam stabilizer, carbon fiber, carbon black, nano-scale insulation material and water are taken by weight; wherein Portland cement is 50 parts of early-strength cement of model 425R The slag is 60 parts, and the selected mesh number is ≥ 200 mesh metal slag powder; the foaming agent is 5.5 parts, and hydrogen peroxide is selected as the foaming agent; wherein the foam stabilizer is 1.5 parts, and the foam stabilizer refers to any material that can improve the stability of the bubbles. , the material that prolongs the half-life of foam collapse can be called a foam stabilizer. As far as the present invention is concerned, the foam stabilizer can be selected in powder or liquid form; powdered carbon black is 2 parts; 0.5 parts; the final water is 50 parts.

Embodiment 2

[0033] Embodiment 2: Portland cement, slag, blowing agent, foam stabilizer, carbon fiber, carbon black, nano-scale insulation material and water are taken by weight; wherein Portland cement is 40 parts of early-strength cement of model 425R ; The slag is 50 parts, and the selected mesh number is ≥ 200 mesh metal slag powder; the foaming agent is 4 parts, and hydrogen peroxide is selected as the foaming agent; wherein the foam stabilizer is 1 part, and the foam stabilizer refers to anything that can improve the stability of the bubbles. , the material that prolongs the half-life of foam collapse can be called a foam stabilizer. As far as the present invention is concerned, the foam stabilizer can be selected in powder or liquid form; powdered carbon black is 2.5 parts; 1 part; final water is 60 parts.

Embodiment 3

[0034] Embodiment three: Portland cement, slag, foaming agent, foam stabilizer, carbon fiber, carbon black, nano-scale insulation material and water are taken by weight; wherein Portland cement is 45 parts of early-strength cement of model 425R ; The slag is 55 parts, and the selected mesh number is ≥ 200 mesh metal slag powder; the foaming agent is 4.75 parts, and hydrogen peroxide is selected as the foaming agent; wherein the foam stabilizer is 1.25 parts, and the foam stabilizer refers to anything that can improve the stability of the bubbles. , the material that prolongs the half-life of foam collapse can be called a foam stabilizer. As far as the present invention is concerned, the foam stabilizer can be selected in powder or liquid form; powdered carbon black is 2.25 parts; 0.75 parts; final water is 55 parts.

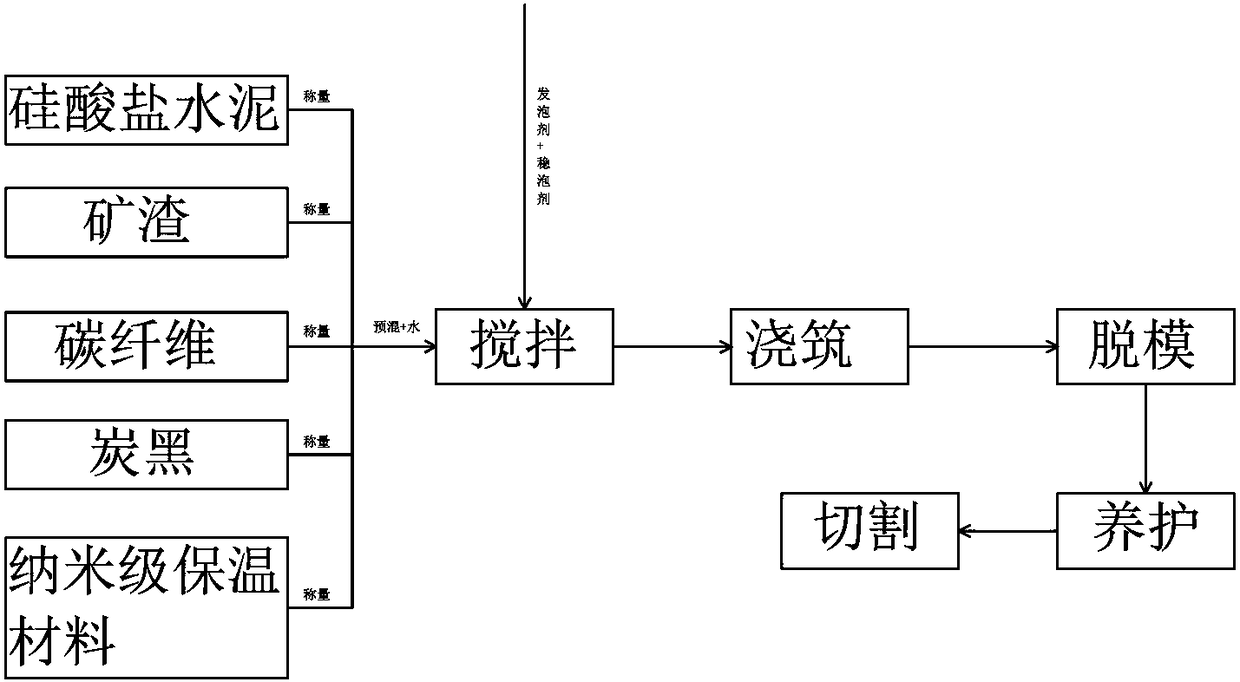

[0035] The production method is as follows: after weighing and premixing Portland cement, slag, carbon fiber, carbon black, and nano-scale insulation materials a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com