Loaded antistatic agent encapsulated in modified nano-mesoporous material and its preparation method and application

A technology of nano-mesoporous materials and antistatic agents, which is applied in the field of antistatic agents and their preparation, can solve the problems of reducing the heat-resistant temperature and surface properties of materials, the dependence of environmental humidity that is not resistant to scrubbing, and poor antistatic durability. Achieve the effects of improving orderly migration, improving timeliness and durability, and reducing timeliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Modification of nano-mesoporous materials

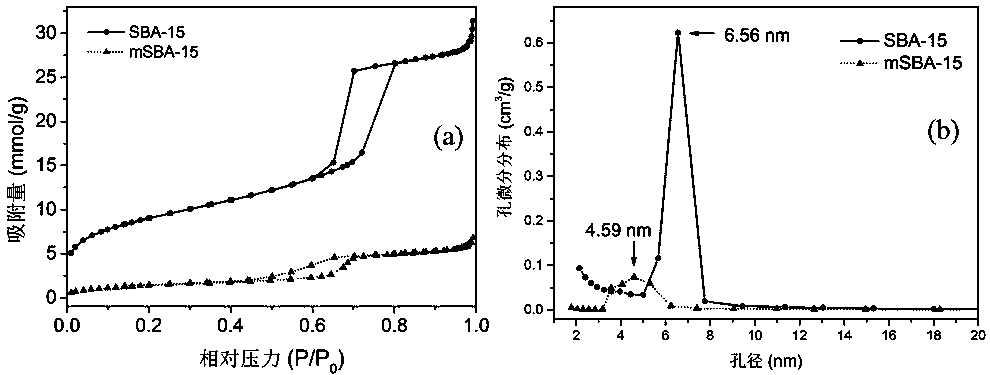

[0032]Mix 1.0 g of nano-mesoporous material SBA-15 with 50 mL of absolute ethanol and ultrasonically disperse for 15 minutes to obtain a SBA-15 dispersion; dissolve 3 g of 3-aminopropyltriethoxysilane (APTES) in absolute ethanol APTES solution with a concentration of 10 wt% was obtained in APTES solution; the APTES solution was mixed with the SBA-15 dispersion and refluxed for 12 hours; after cooling to room temperature, it was filtered, washed and dried to obtain the pore wall modified nano-mesoporous material mSBA-15. figure 1 and Table 1 for SBA-15 and mSBA-15 Adsorption / desorption test results show that both SBA-15 and mSBA-15 have the characteristics of mesoporous materials, which are typical mesoporous materials, and due to the modification of APTES, the specific surface area of mSBA-15 ( ), pore volume ( ), average pore diameter ( ) and maximum aperture ( ) are smaller than those of SBA-15.

[0033] Tabl...

Embodiment 2

[0042] Mix 1.0 g of nano-mesoporous material SBA-15 with 50 mL of absolute ethanol and ultrasonically disperse for 15 minutes to obtain a SBA-15 dispersion; dissolve 2.0 g of APTES in absolute ethanol to obtain a 10 wt% APTES solution; After mixing the APTES solution and the SBA-15 dispersion, reflux for 12 hours; after cooling to room temperature, filter, wash, and dry to obtain the pore wall modified nano-mesoporous material mSBA-15 ( figure 1 ,Table 1);

[0043] (2) Preparation of surfactant-type antistatic agent / pore wall modified nano-mesoporous material-loaded antistatic agent

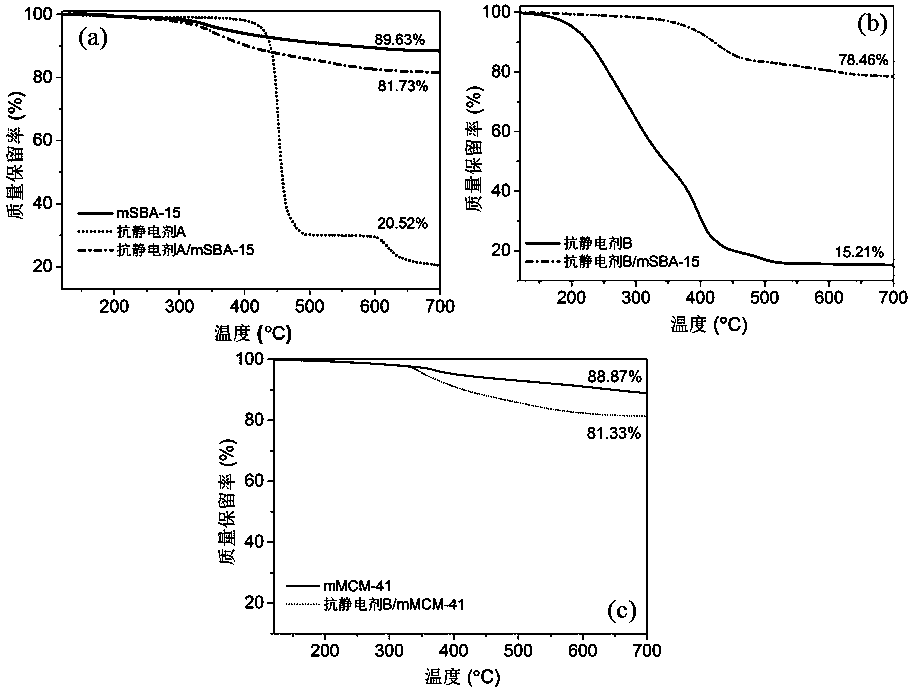

[0044] Dissolve 1.0 g of surfactant-type antistatic agent B (Table 2) in 33 mL of absolute ethanol; add 0.5 g of mSBA-15 into the above-mentioned absolute ethanol solution, and disperse ultrasonically for 30 minutes; Stir for 60 hours, filter, wash and dry to obtain the load-type antistatic agent——antistatic agent B / mSBA-15. According to the TGA curve ( figure 2 b) and formula (1) to calculat...

Embodiment 3

[0046] (1) Modification of nano-mesoporous materials

[0047] Mix 1.0 g of nano-mesoporous material MCM-41 with 40 mL of absolute ethanol and ultrasonically disperse for 15 minutes to obtain the MCM-41 dispersion; dissolve 2.5 g of APTES in absolute ethanol to obtain a 20 wt% APTES solution; After mixing the APTES solution and the MCM-41 dispersion, reflux for 24 hours; after cooling to room temperature, filter, wash, and dry to obtain the pore wall modified nano-mesoporous material mMCM-41;

[0048] (2) Preparation of surfactant-type antistatic agent / pore wall modified nano-mesoporous material-loaded antistatic agent

[0049] Dissolve 1.0 g of surfactant-type antistatic agent B (Table 2) in 33 mL of absolute ethanol; add 0.5 g of mMCM-41 into the above absolute ethanol solution, and disperse ultrasonically for 30 minutes; Stir for 55 hours, filter, wash, and dry to obtain the loaded antistatic agent——antistatic agent B / mMCM-41. According to the TGA curve ( figure 2 c) and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com