Enzymolysis treatment method of algae

A treatment method and enzyme treatment technology, which is applied in the compound enzyme treatment of seaweed and the field of enzymatic hydrolysis of seaweed, can solve the problems of low extraction rate of sodium alginate, cumbersome operation, long enzymatic hydrolysis time, etc., and shorten the reaction time of seaweed enzymatic hydrolysis , simple operation, high total yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1 A kind of enzymolysis treatment method of seaweed

[0031] Step 1. Material preparation

[0032] The seaweed used includes sargassum, hijiki and carrageenan, with a mass ratio of 5:2:2;

[0033] The sargassum: the water content is 15-16%; the hijiki: the water content is 12-14%; the carrageenan: the water content is 13-14%.

[0034] Step 2. Preprocessing

[0035] Wash sargassum, hijiki, and carrageenan with fresh water, dry them at 90-98°C for 40-45 minutes, grind them to 200-mesh fine powder after drying, and mix them to obtain mixed seaweed powder;

[0036] Add 3 times the mass of deionized water to the seaweed powder, and stir evenly to obtain seaweed slurry.

[0037] Step 3, enzyme treatment

[0038] Add the seaweed slurry into the reaction kettle, adjust the reaction pH, adjust the reaction temperature, add complex enzyme, the amount of enzyme added accounts for 0.7% of the mass of the seaweed homogenate; react for 60 hours, after the reaction is c...

Embodiment 2

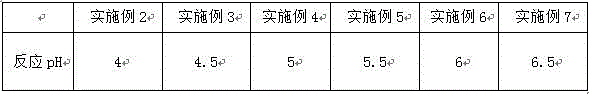

[0042] The single factor analysis experiment of embodiment 2 reaction pH

[0043]

[0044] In the enzyme treatment step, the reaction pH of Example 2-7 is adopted, and the reaction temperature is adjusted to be 46°C. Among the compound enzymes added, papain is selected as protease, β-glucosidase is selected as cellulase, and β-glucosidase is selected as pectinase. Protopectinase; enzymatically hydrolyze seaweed according to the method of Example 1.

Embodiment 8

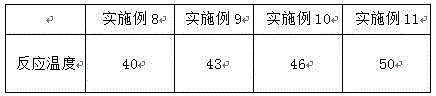

[0045] Embodiment 8 reaction temperature single factor analysis experiment

[0046]

[0047] In the enzyme treatment step, adopt the reaction temperature of Example 8-11, adjust the reaction pH to be 5.5, in the compound enzyme added, protease is all selected papain, cellulase is all selected β-glucosidase, pectinase is all selected original Pectinase; according to the method of embodiment 1, seaweed is enzymolyzed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com