A far-infrared carbon fiber integrated wall heating board and its production process

A technology of far-infrared carbon fiber and production process, applied in heating methods, lighting and heating equipment, space heating and ventilation, etc., can solve problems such as high energy consumption, high pollution, high radiation, etc., and achieve a better indoor environment and thermal performance Good, low thermal conductivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

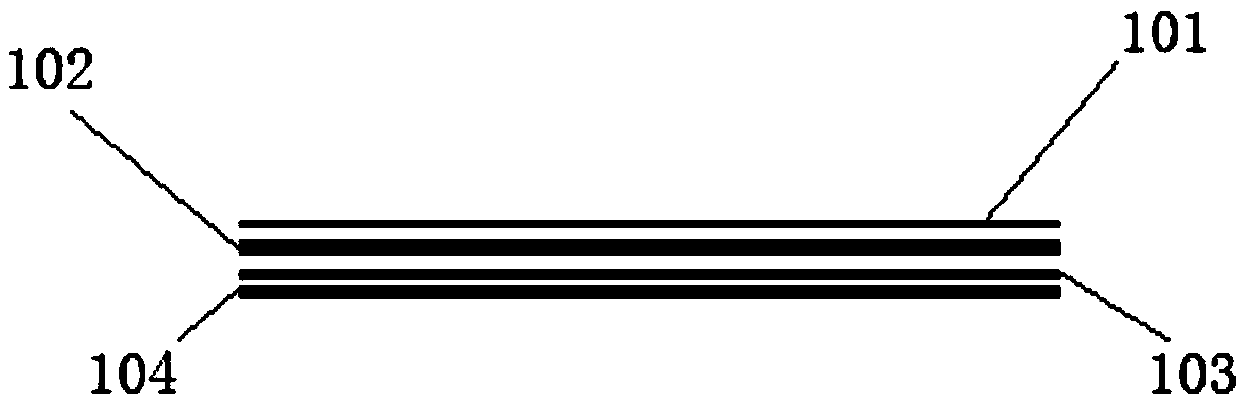

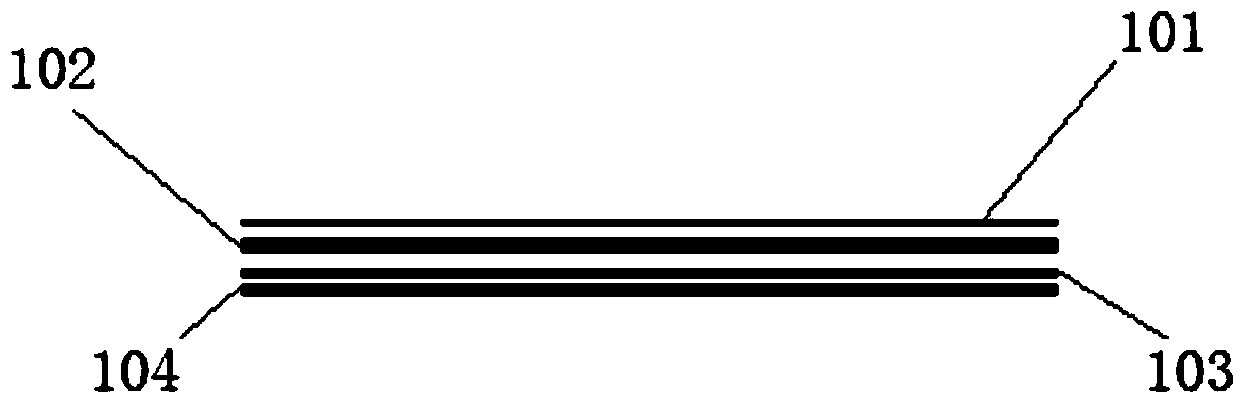

[0045] refer to figure 1 As shown, a far-infrared carbon fiber integrated wall heating panel and its production process, wherein:

[0046] A far-infrared carbon fiber integrated wall heating plate, according to the order from top to bottom, includes: a protective layer 101, a PU layer 102, a carbon fiber heating layer 103 and a decorative layer 104; the carbon fiber heating layer 103 is provided with carbon fiber connectors;

[0047] As an example, the carbon fiber connector is set to a twisted-pair multi-strand structure, that is, a plurality of connecting wire-like compression structures made by a similar crystal head structure, and the external copper-nickel structure Connect the cable for plug-in connection similar to the network port;

[0048] As an example of a practical application, when the two-strand joint of the carbon fiber bra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com