High voltage electrolyte for lithium ion battery

A lithium-ion battery, electrolyte technology, applied in secondary batteries, circuits, electrical components, etc., can solve problems such as shortening battery life, battery structure changes, and difficulty meeting requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

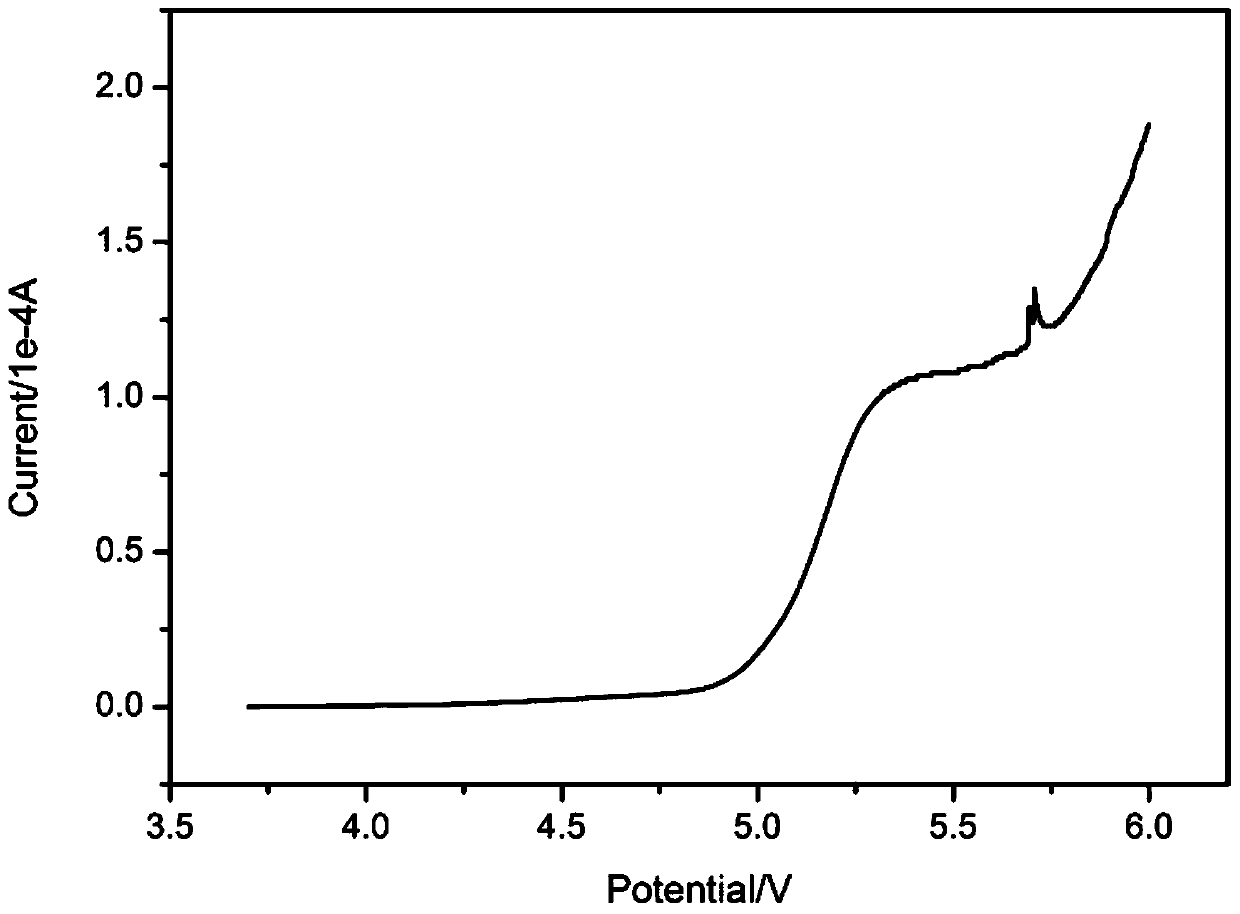

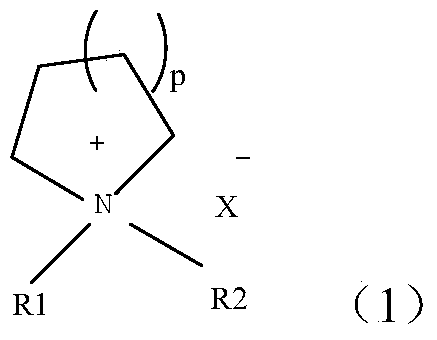

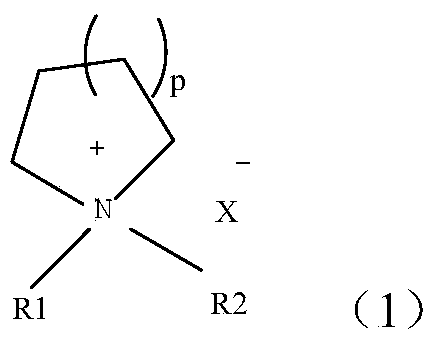

[0023] Weigh fluoroethylene carbonate, methyl-2,2,2-trifluoroethyl carbonate, and ethyl methyl carbonate at a mass ratio of 4:1:15 to form an organic mixture; add N-butylene to the mixture in turn Base, methylpyrrolidine (trifluoromethylsulfonyl) imide salt, vinylene carbonate, which account for 2% and 1.5% of the total mass respectively; finally slowly add 1M / L lithium hexafluorophosphate and stir to obtain the mixture of Example 1 Li-ion battery high voltage electrolyte. The electrolytic solution has an oxidation potential of 4.9-5.0V measured on a metal platinum electrode by using a three-electrode system.

Embodiment 2

[0025] Weigh fluoroethylene carbonate, ethyl methyl carbonate, and γ-butyrolactone in a mass ratio of 2:7:1 to form an organic mixture; add N-butyl, methylpyrrolidine (trifluoromethyl) to the mixture in turn Sulfonyl)imide salt, vinylene carbonate, which account for 2% and 1% of the total mass respectively; finally slowly add 0.9M / L lithium hexafluorophosphate and 0.1M / L lithium bisoxalate borate and stir to obtain the product of Example 2 Li-ion battery high voltage electrolyte. The electrolytic solution adopts a three-electrode system to measure the oxidation potential on the metal platinum electrode to be 5.0V.

Embodiment 3

[0027] Weigh fluoroethylene carbonate and ethyl methyl carbonate to make an organic mixture according to the mass ratio of 1:4; add N-butyl, methylpiperidinium (trifluoromethylsulfonyl) imide salt to the mixture in turn , vinylene carbonate, vinyl sulfite, which account for 2%, 1% and 0.5% of the total mass respectively; finally slowly add 0.9M / L lithium hexafluorophosphate and 0.1M / L bis(trifluoromethylsulfonyl)imide After stirring the lithium evenly, the high-voltage electrolyte solution for the lithium-ion battery of Example 3 was obtained. The electrolytic solution adopts a three-electrode system to measure the oxidation potential on the metal platinum electrode to be 4.95V.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Oxidation potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com