Large power fiber laser with inner cavity frequency doubling

A fiber laser and fiber laser technology, applied in the direction of lasers, laser components, phonon exciters, etc., can solve the problems of low output power and low frequency conversion efficiency of visible light, so as to improve conversion efficiency, increase output power, and stabilize The effect of doubling the output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

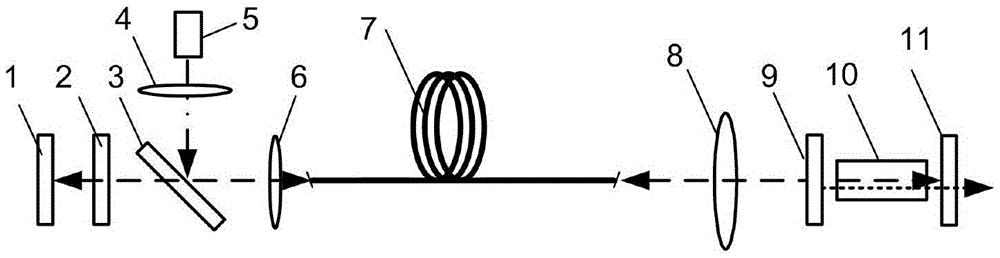

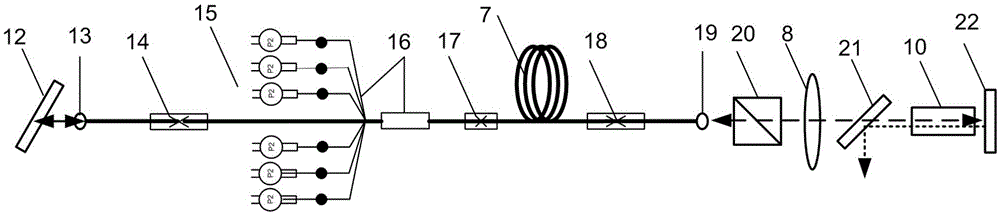

[0027] Please refer to the attached figure 1 , which is the first embodiment of a high-power intracavity frequency-doubling fiber laser, in which it includes: a fiber laser resonator and an intracavity frequency doubling system.

[0028] The fiber laser resonator includes: a fiber laser high-power pump source 5, a collimator lens 4 is arranged in front of the high-power pump source 5, and a two-color laser placed in a 45° direction is arranged in front of the collimator lens 4. mirror 3, the front of the dichroic mirror 3 and the collimating lens 4 in the vertical direction are provided with a collimating lens 6, a large mode field double-clad polarization-maintaining doped rare earth fiber 7 and a beam expander lens 8, and the described dichroic mirror 3 and A narrow line width filter 2 and a total reflection mirror 1 are also provided behind the collimator lens 4 in the vertical direction.

[0029] Wherein, the high-power pumping source 5 is composed of n multimode semicond...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com