Method for designing riser during sand casting process of thin wall casting of solid of revolution based on shrinkage defect prediction

A technology of thin-walled castings and sand casting, which is applied in the direction of casting molding equipment, casting molds, and casting mold components. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0042] Specific Embodiment 1: The riser design method in the process of sand casting of thin-walled castings based on shrinkage porosity prediction described in this embodiment is carried out according to the following steps:

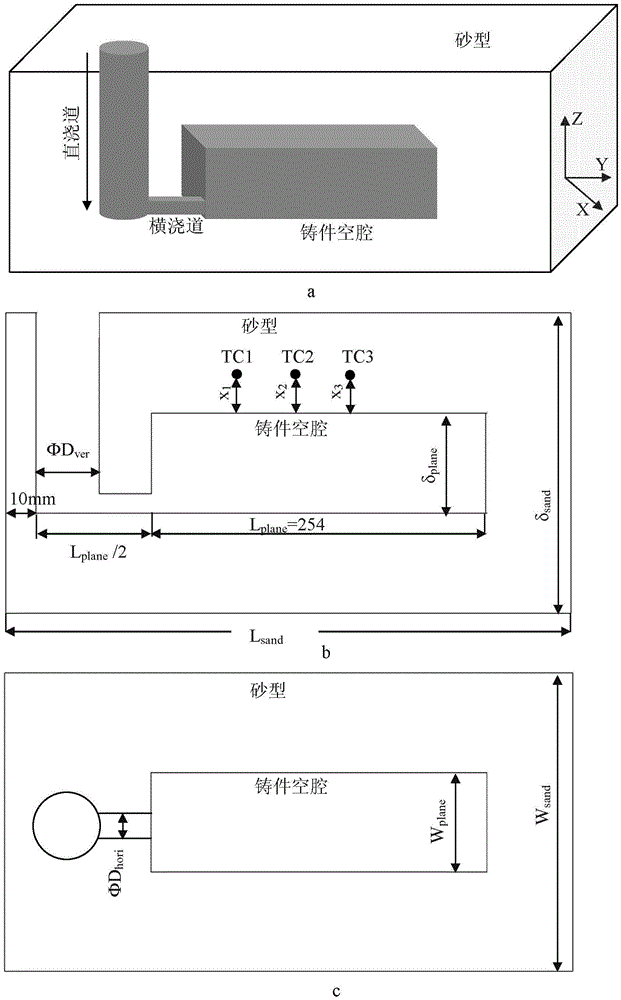

[0043] Step 1. Design a physical simulation experiment to obtain the heating curve of different points in the sand mold:

[0044] Carry out numerical simulation of the temperature field, and directly determine the interface heat transfer coefficient of the alloy / sand mold (between the alloy and the sand mold) by using the heat flux density versus time curve provided by the experiment;

[0045] Step 1 (1), the shape and size characteristics of the casting in the physical simulation experiment: the casting is a rectangular plate, and the length of the rectangular plate is represented by L plane Indicates that the plate thickness δ plane Minimum wall thickness δmin of thin-walled castings with rotary bodies casting and the maximum wall thickness δmax ca...

specific Embodiment approach 2

[0058] Specific embodiment two: in the step one (1) described in this embodiment, the length L of the rectangular plate plane It is 254mm. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

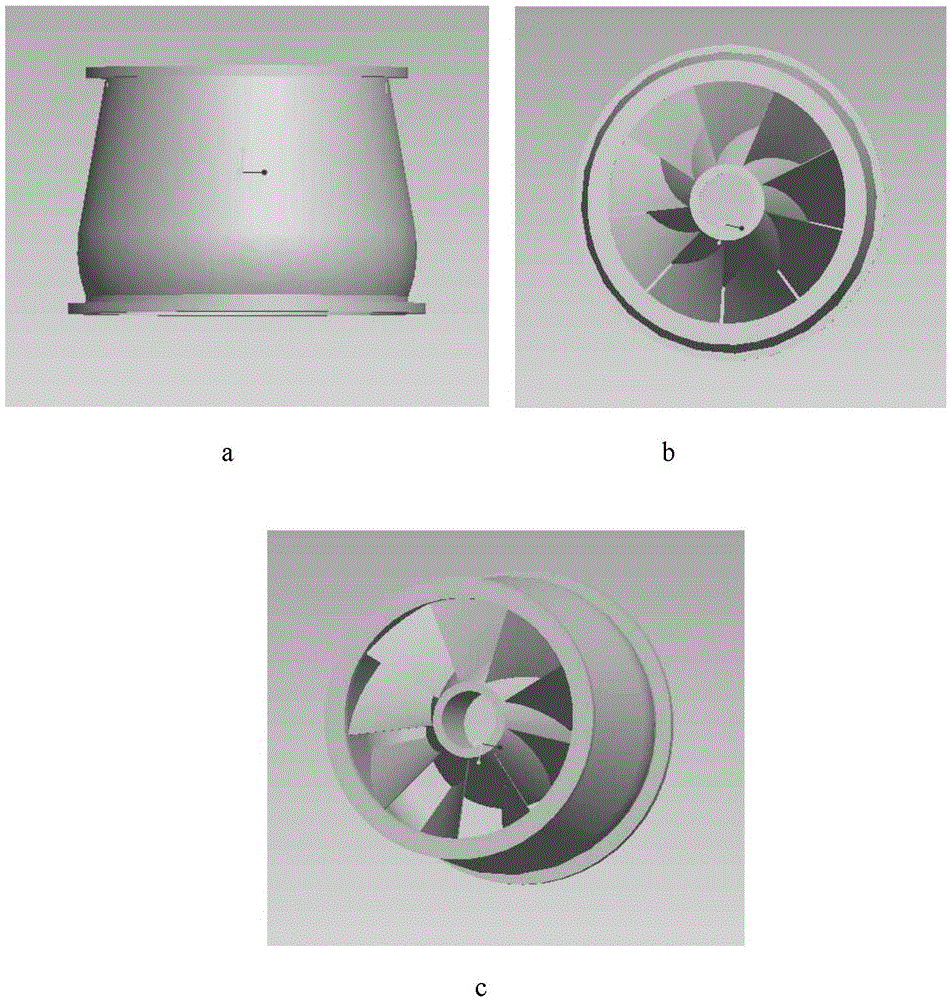

[0059] Specific implementation mode three: In this implementation mode, in step one,

[0060] The thin-walled casting of the rotary body is selected from the cylinder blade casting. The cylinder blade casting is made of duplex stainless steel. The materials of the duplex stainless steel are: C: 0.02wt%, Si: 0.58wt%, Mn: 0.88wt%, S: 0.04wt%, P: 0.04wt%, Ni: 5.00wt%, Mo: 3.00wt%, Cu: 0.60wt%, N: 0.25wt%, Cr: 22.00wt%, the balance is Fe. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com