Centrifugal settling-type bioreactor for continuous culture of plant cells

A technology of bioreactor and centrifugal sedimentation, which is applied in the direction of specific-purpose bioreactor/fermenter, bioreactor/fermenter combination, tissue cell/virus culture device, etc., which can solve the problem of high cost, waste, plant cell The interception rate is not very high, to achieve the effect of preventing pollution and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

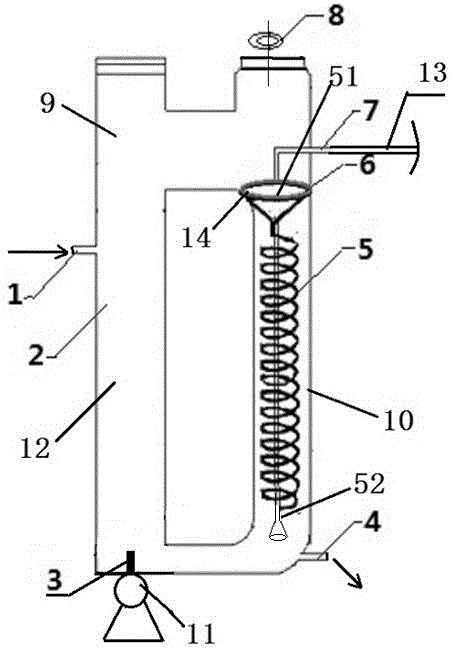

[0018] Such as figure 1 As shown, the centrifugal sedimentation bioreactor for continuous cultivation of plant cells includes a main body 9 with a U-shaped structure as a whole. The main body 9 includes a riser 2 and a downcomer 10. The bottom and top positions are connected respectively; the liquid inlet 1 is also provided on one side of the ascending liquid area 2, and the cell harvesting port 4 is provided at the bottom position of the descending liquid part 10; the ascending liquid part 2 is also provided with a The air nozzle 3, the air nozzle 3 sprays upward airflow, and then drives the culture solution 12 in the ascending liquid part 2 to rise; the descending liquid part 10 is provided with a sealed funnel 6 and a spiral tube 5 from top to bottom, and the top of the sealed funnel 6 is connected to the The inner wall of the downcomer 10 of the main body 9 is bonded and sealed, and the bottom of the sealed funnel 6 is connected to the inlet 51 of the spiral tube 5 . The ...

Embodiment 2

[0025] The method for continuously culturing cells using a bioreactor comprises the steps of: adopting the culture medium to add NAA and IAA MS medium to plant cells in a U-shaped centrifugal sedimentation bioreactor for cultivating, keeping the air nozzle from coming out The aeration rate is 200-300vvm, the culture temperature is 20-30°C, and the culture is 25-35 days.

[0026] In the above embodiment, the reactor includes a main body 9 with a U-shaped structure as a whole, the main body 9 includes a riser 2 and a downcomer 10, and the corresponding bottom and top positions of the riser 2 and the downcomer 10 communicate respectively; A liquid inlet 1 is also provided on one side of the ascending liquid area 2, and a cell harvesting port 4 is provided at the bottom of the descending liquid part 10; The upward airflow is ejected, and then the culture solution 12 in the ascending liquid part 2 is driven to rise; the descending liquid part 10 is provided with a sealed funnel 6 a...

Embodiment 3

[0031] The device used in this example is figure 1shown. Glycyrrhizae cells were continuously cultured through this example, the initial inoculation density was 5 g (dry weight) / L, the culture medium was MS medium supplemented with NAA and IAA, the aeration rate was 300vvm, and the culture temperature was 25°C. At the same time, the cut-off efficiency and kLa of the reactor were measured using licorice cells as the material. The results showed that under conditions suitable for plant cell growth (aeration rate of 0.3vvm, perfusion rate of 10%), the cell retention efficiency reached 100%, the volumetric oxygen dissolution coefficient kLa was 5.0, and the maximum cell biomass reached 14.0g after 27 days / L, higher than the maximum biomass of 12.0g / L in batch culture. The device involved in the invention is very suitable for the continuous cultivation of plant cells and can be popularized and applied on a large scale.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com