Raw material skin unhairing method

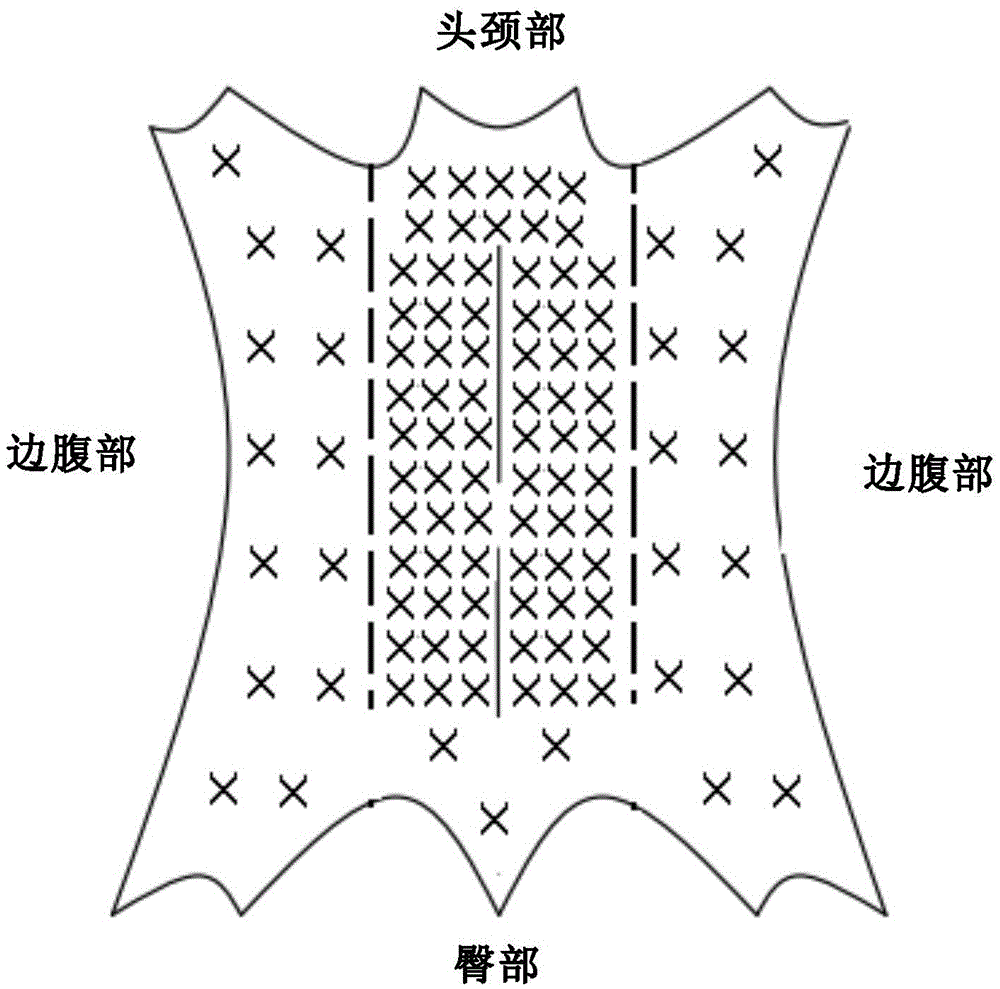

A raw material, animal skin technology, applied in small raw hide/large raw hide/leather/fur treatment, small raw hide/large raw hide/leather hide/fur chemical treatment, chemical treatment before tanning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The raw hide is sheepskin preserved in salt, and the weight is calculated as a percentage of skin weight.

[0052] (1) Washing: 300% clean water washing, temperature: 25°C, rotation speed: 3-6rmp, to remove salt and dirt attached to the leather surface;

[0053] (2) Pre-soaking water: add 400% water, 0.5% soda ash and 0.5% FG-B surfactant to the drum, temperature: 25°C, speed: 3-6rmp, rotate for 5 minutes and stop for 55 minutes, 5 times, a total of 5h, let stand for 10h; remove the flesh, remove the subcutaneous tissue.

[0054] (3) Main immersion: Add 400% water, 0.5% soda ash and 0.5% FG-B surfactant to the drum, temperature: 25°C, speed: 3-6rmp, rotate for 5 minutes and stop for 55 minutes, 6 times, a total of 6h.

[0055] (4) Hair removal: add 3% animal skin compound enzyme depilatory agent to the main soaking bath (fast depilatory speed), the specific formula is: Novozymes SG protease 2kg, 1398 protease 12kg, elastase TX2kg, lipase UltraG2kg , sodium lauryl sul...

Embodiment 2

[0064] The raw hide is sheepskin preserved in salt, and the weight is calculated as a percentage of skin weight.

[0065] (1) Washing: 300% clean water washing, temperature: 25°C, rotation speed: 3-6rmp, to remove salt and dirt attached to the leather surface;

[0066] (2) Pre-soaking water: add 400% water, 0.5% soda ash and 0.5% FG-B surfactant to the drum, temperature: 25°C, speed: 3-6rmp, rotate for 5 minutes and stop for 55 minutes, 5 times, a total of 5h, let stand for 12h; remove the flesh, remove the subcutaneous tissue.

[0067] (3) Main immersion: Add 400% water, 0.5% soda ash and 0.5% FG-B surfactant to the drum, temperature: 25°C, speed: 3-6rmp, rotate for 5 minutes and stop for 55 minutes, 6 times, a total of 6h.

[0068] (4) Hair removal: Add 3% animal skin compound enzyme hair removal agent (medium hair removal speed) to the main soaking bath, the specific formula is: Novozymes PY protease 1.2kg, 1398 protease 8kg, elastase TX1.0kg, Lipase UltraG 2kg, sodium l...

Embodiment 3

[0076] The raw hide is sheepskin preserved in salt, and the weight is calculated as a percentage of skin weight.

[0077] (1) Washing: 300% clean water washing, temperature: 25°C, rotation speed: 3-6rmp, to remove salt and dirt attached to the leather surface;

[0078] (2) Pre-soaking water: add 400% water, 0.5% soda ash and 0.5% FG-B surfactant to the drum, temperature: 25°C, speed: 3-6rmp, rotate for 5 minutes and stop for 55 minutes, 5 times, a total of 5h, let stand for 12h; remove the flesh, remove the subcutaneous tissue.

[0079] (3) Main immersion: Add 400% water, 0.5% soda ash and 0.5% FG-B surfactant to the drum, temperature: 25°C, speed: 3-6rmp, rotate for 5 minutes and stop for 55 minutes, 6 times, a total of 6h.

[0080] (4) Hair removal: Add 3% animal skin compound enzyme depilatory agent (slower hair removal speed) to the main soaking bath, the specific formula is: Novozymes’ PY protease 0.5kg, Novozymes’ SG protease 0.5kg, Mix 5kg of 1398 protease, 0.5kg of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com