High-temperature liquid-state slag dry type centrifugation and granulation waste heat recycling system and method

A waste heat recovery system and liquid slag technology, applied in recycling technology, waste heat treatment, energy efficiency improvement, etc., can solve problems such as waste of high-quality waste heat resources, and achieve continuous treatment, enhanced heat exchange, and uniform air distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The specific embodiment of the present invention will be described below in conjunction with accompanying drawing:

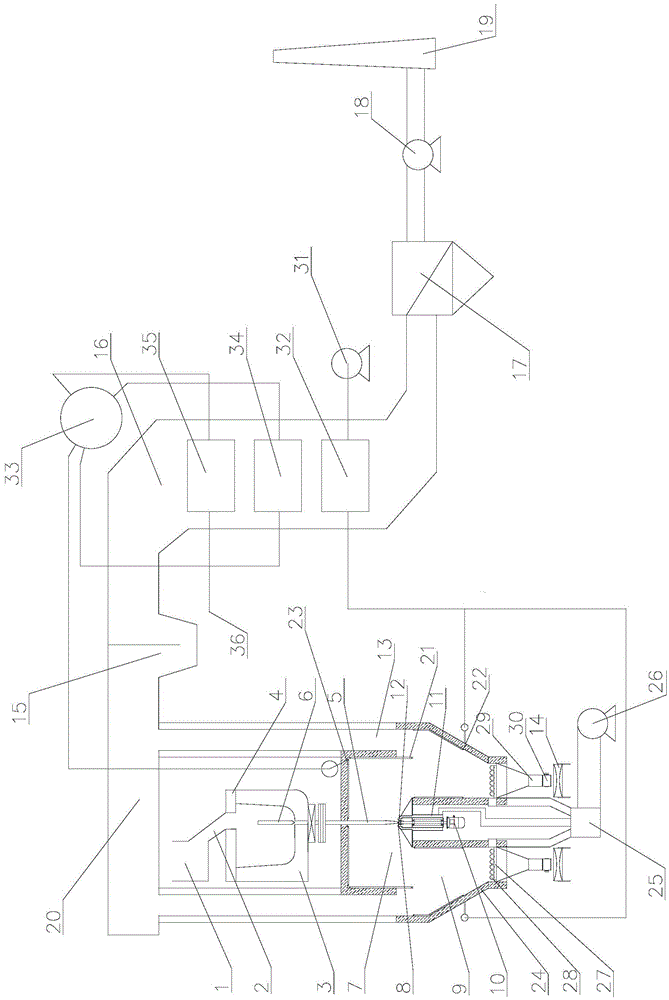

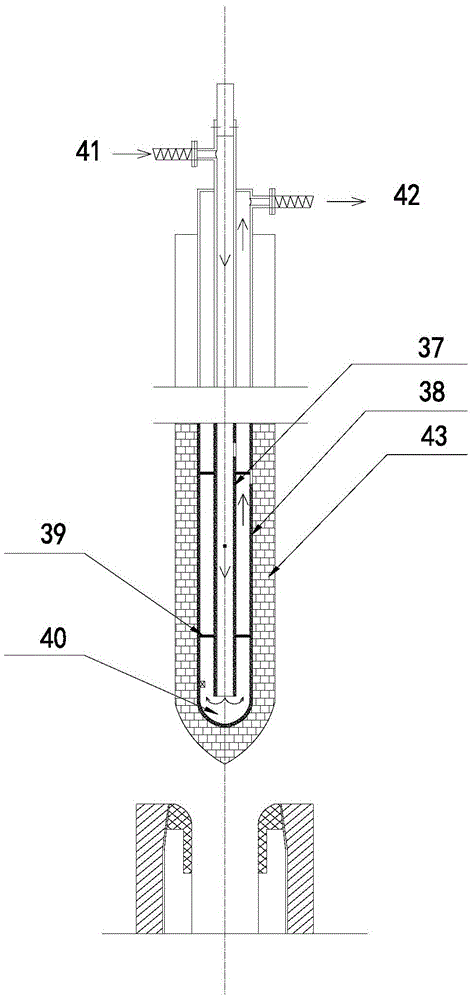

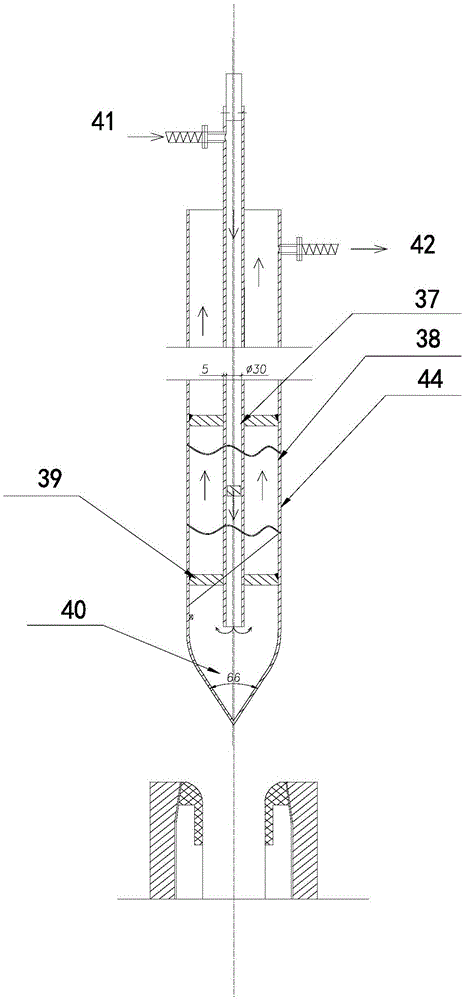

[0044] see Figure 1 to Figure 6 As shown, a high-temperature liquid slag dry-type centrifugal granulation waste heat recovery system of the present invention includes a liquid slag drainage system, a liquid slag buffer system, a liquid slag granulation and heat exchange system, a slag particle conveying system and waste heat recovery system.

[0045] The liquid slag drainage system includes a slag ditch 1, a baffle and a slag outlet 2; the slag ditch inlet is directly connected to the blast furnace slag outlet, and the slag ditch slag outlet 2 is located above the slag buffer system inlet; the baffle is located at the bottom of the slag ditch; The slag ditch has a plurality of slag outlets 2 .

[0046] The liquid slag buffer system consists of multiple independent slag bags; the slag bag includes a slag bag body 3, a cover 4, a slag drop pipe 5 and a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com