Production method of ultra-low sulfur IF steel

A production method, ultra-low sulfur technology, applied in the field of iron and steel metallurgy, can solve the problems of increasing the production cost of steelmaking, prolonging the vacuum treatment time, and affecting the production rhythm, so as to improve the cleanliness of molten steel, reduce the RH desulfurization process, and reduce the cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The following method is used to produce ultra-low sulfur IF steel.

[0039] (1) Hot metal pretreatment

[0040] The molten iron before pretreatment satisfies the following conditions: molten iron temperature>1300℃, C≥4.5%, S≤0.06%.

[0041] (2) Converter smelting

[0042] Condition of semi-steel into converter: carbon ≥ 3.5%, temperature > 1280℃, S ≤ 0.003%. The loading capacity is 220-230 tons. The scrap steel does not use slag steel, and uses low-sulfur (S≤0.015%) to clean the scrap steel with an amount of ≤8 tons. Do not use recarburizer to warm up. Argon is blown at the bottom during the whole process of blowing. When the sulfur content of the previous furnace of smelting IF steel is greater than 0.020%, no slag is splashed, and the whole furnace slag is completely drained. See Table 1 for details.

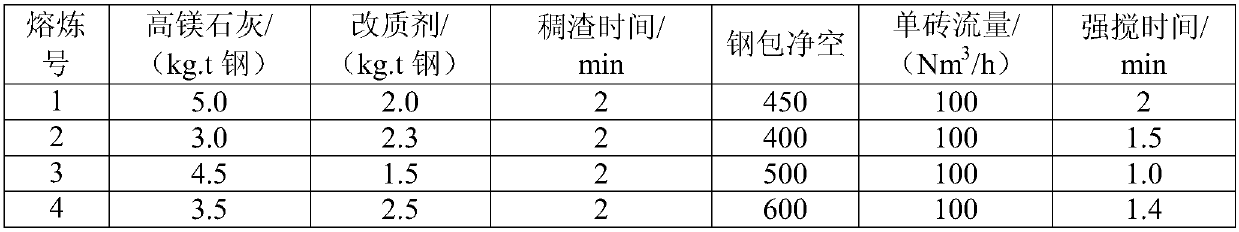

[0043] Table 1 Converter entry conditions

[0044] Melting number

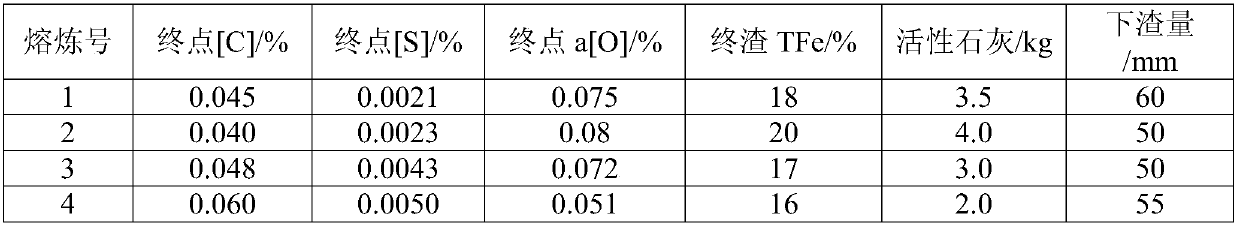

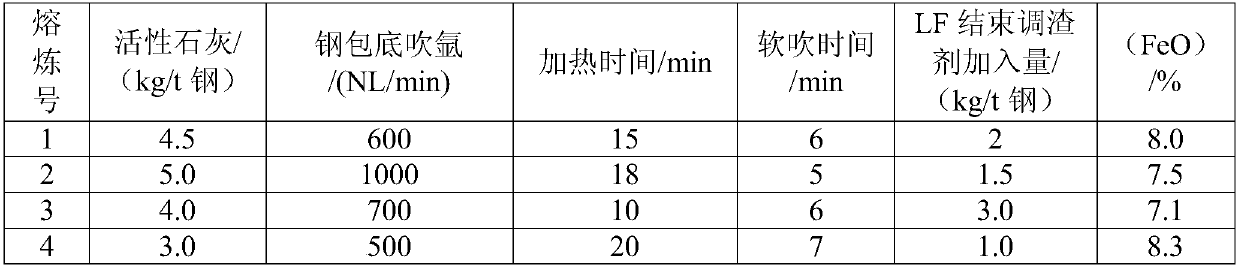

[0045] Requirements for slag adjustment at the converter end point: add 3-5kg / t st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com