Guide device for polycrystal ingot casting furnace

A technology of a diversion device and an ingot furnace, which is applied to the growth of polycrystalline materials, crystal growth, single crystal growth, etc., can solve the problems of supercooling, inconvenient operation of the furnace, and inability to observe the state of the ingot furnace, and achieves heat reduction. , the effect of reducing the degree of supercooling and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

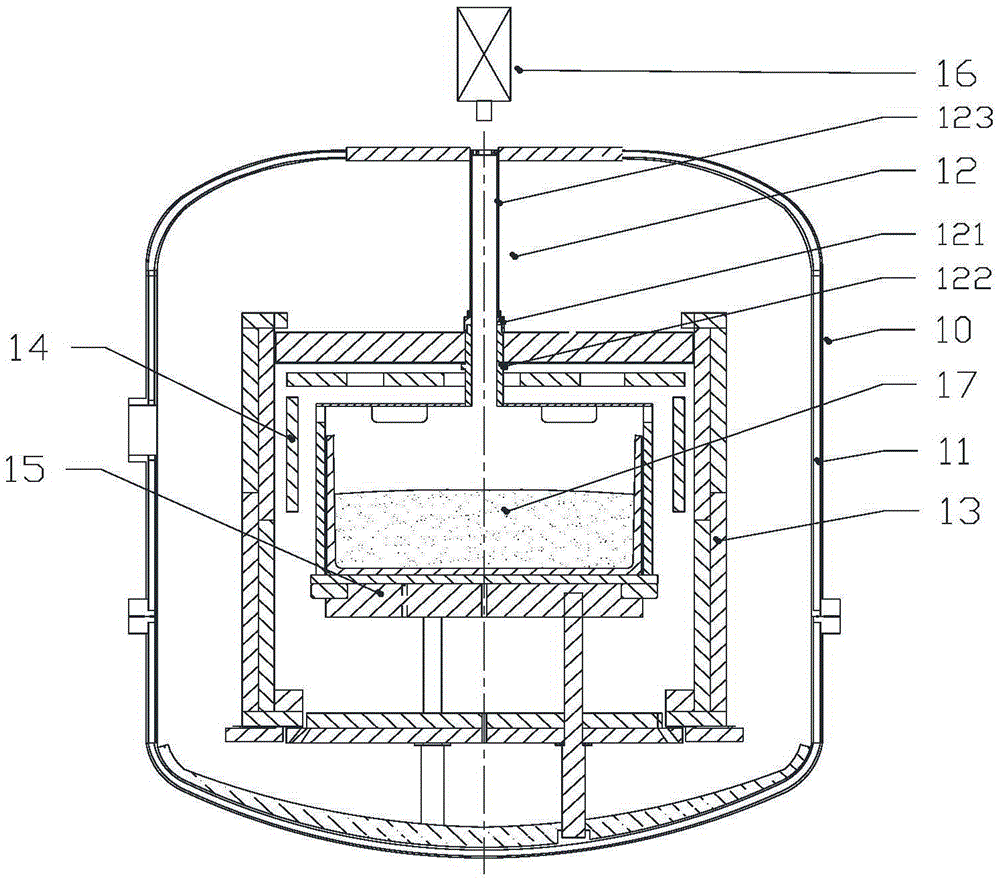

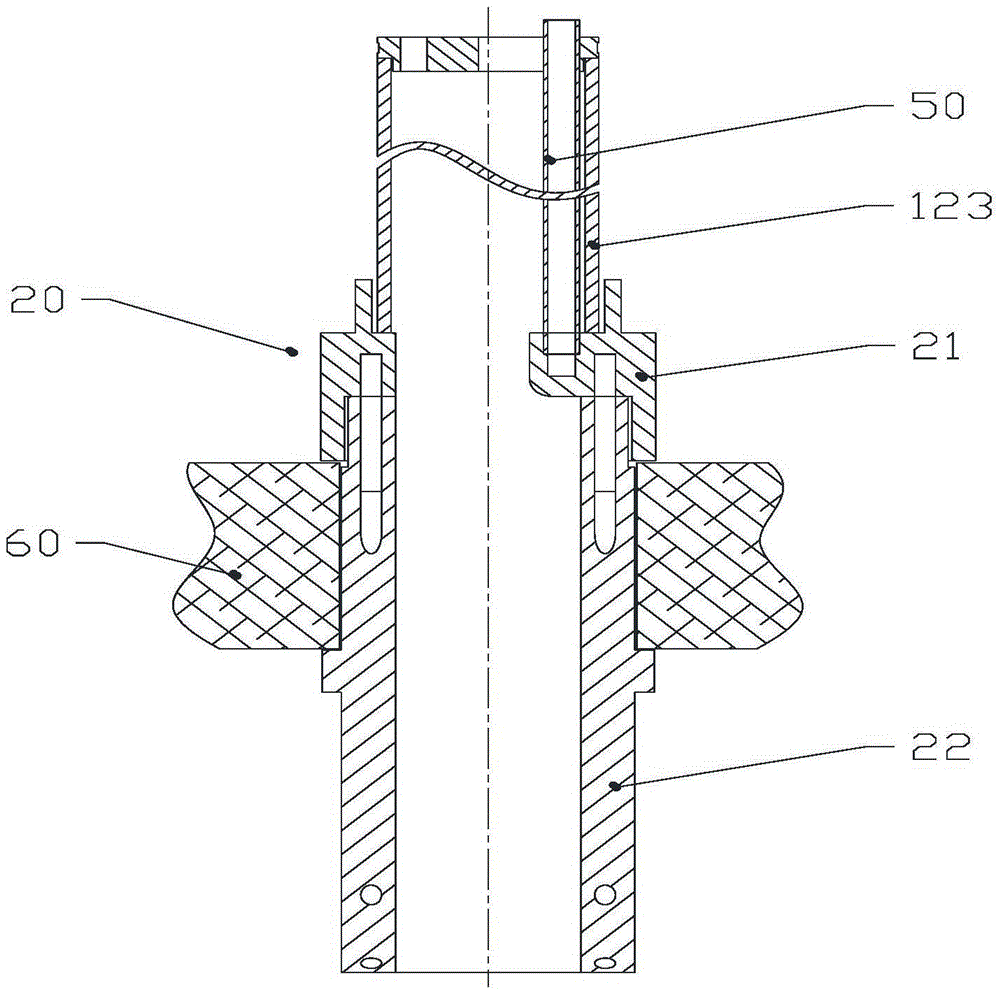

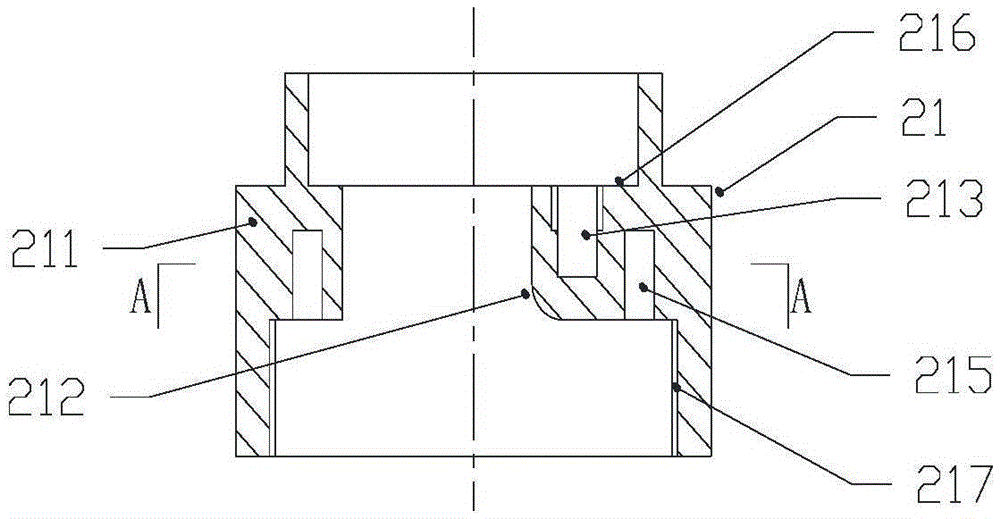

[0066] A kind of diversion device for polycrystalline ingot furnace of the present invention, such as figure 2 As shown, the flow guiding device 20 includes an adapter cylinder 21 and a flow guiding cylinder 22 . The lower end of the fitting cylinder 21 is provided with an internal thread 217 , and the upper end of the guide cylinder 22 is provided with an external thread 224 ; The middle part of the guide tube 22 is provided with a flange 223 extending circumferentially along its outer surface, such as Figure 5 As shown, the flange 223 surrounds the outer surface of the guide tube 22 for a week, and forms a ring-shaped protruding structure on the surface of the guide tube 22 to play a position-limiting and fixing role. In application, the upper end of the guide tube 22 passes through the through hole in the middle of the top insulation board 60 of the heat insulation cage, and is axially assembled with the adapter sleeve 21 arranged above the top insulation board 60, and t...

Embodiment approach 2

[0075] A kind of diversion device for polycrystalline ingot furnace of the present invention, such as Figure 11 , Figure 12 As shown, the flow guide device 30 includes a guide cylinder part 31 and an air inlet platform part 32, and the material of the guide cylinder part 31 and the air inlet platform part 32 is graphite with a lower price, preferably isostatic graphite, It can also be molybdenum or titanium with higher cost. The guide tube part 31 is a cylinder whose middle part is provided with a through hole along the direction of the center line, that is, a cylinder. The internal thread 37 extends along the centerline of the guide tube part 31, and external threads can also be provided as required. A buffer cavity 35 extending in the circumferential direction is arranged in the wall of the upper end of the guide tube part 31. The buffer cavity 35 is an annular cavity around the center line of the guide tube part 31. The buffer cavity 35 is located in the Below the inne...

Embodiment approach 3

[0083] A kind of diversion device for polycrystalline ingot furnace of the present invention, such as Figure 18 , Figure 19As shown: the guide device 40 includes a fastening part 45, a buffer cavity part 41, an air intake pipe part 42, a connecting pipe 44 and a guide air pipe 43, the material of which is molybdenum, and high-cost high-temperature-resistant materials such as titanium can also be used . The fastening part 45 is a hollow cylinder, which is arranged on the top of the buffer chamber part 41 and is axially fixed thereto. On the inner wall of the fastening part 45, an internal thread 46 is provided along the centerline of the buffer cavity part 41, and an external thread can also be provided according to local needs. The buffer cavity 41 is an annular cylindrical airtight cavity, mainly composed of an inner wall, an outer wall, an upper end wall and a lower end wall, the inner wall and the outer wall are cylindrical, the inner wall is nested in the outer wall, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com