Waste grease receiving, sampling and pretreating device

A technology of waste oil and sampling tank, applied in sampling device, preparation of test samples, etc., can solve the problems of affecting work efficiency, low impurity removal rate, and increased maintenance frequency, so as to reduce workload, facilitate accuracy, and replace and easy to replace effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

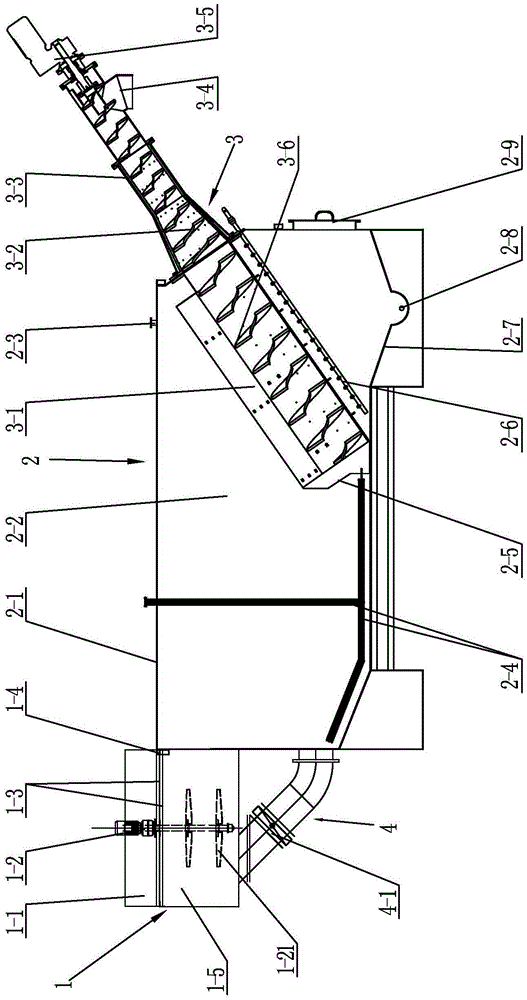

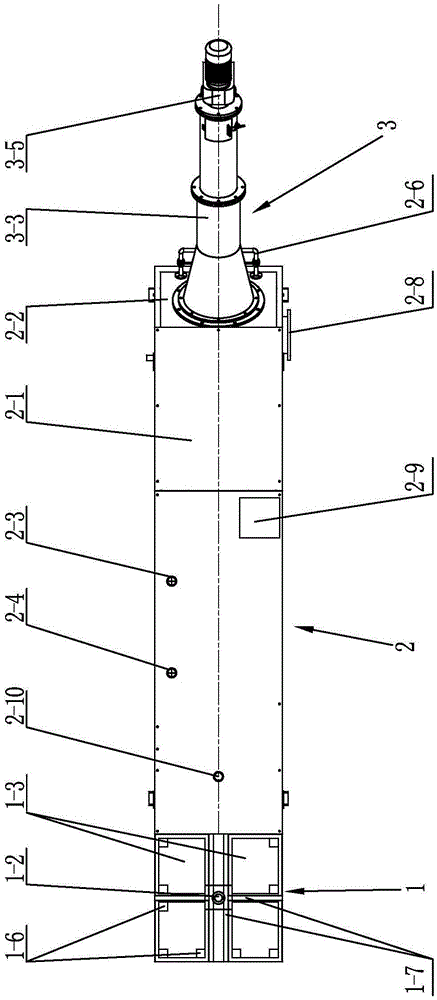

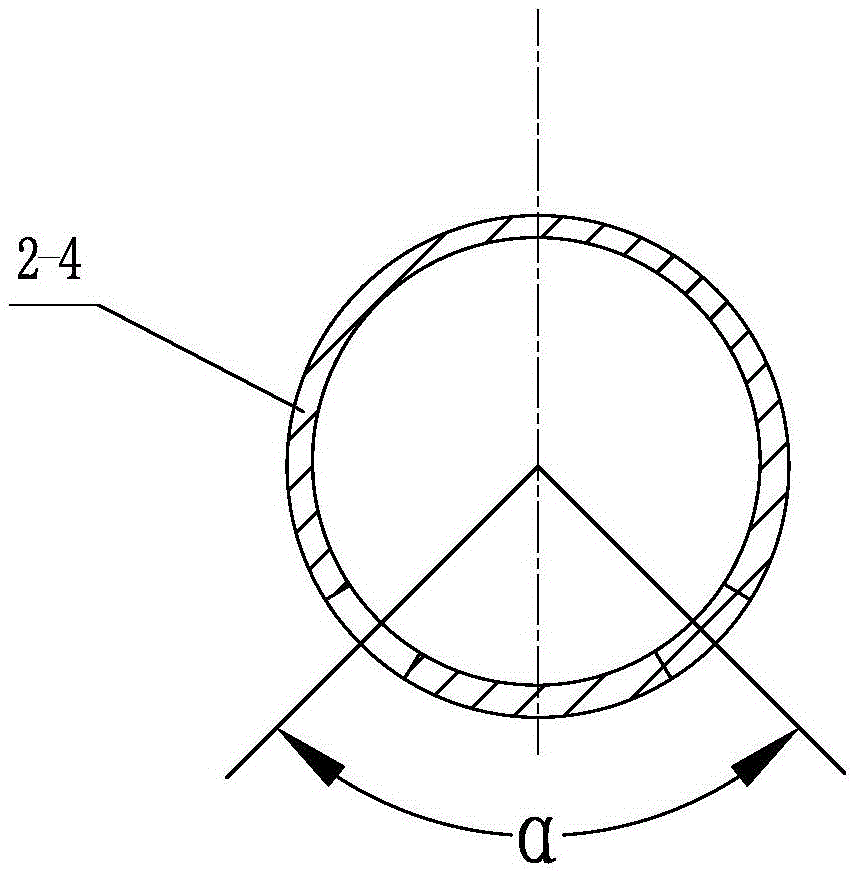

[0023] See figure 1 As shown, the waste grease receiving and sampling pre-treatment device of the present invention includes a sampling tank 1, a pre-processing mechanism 2, a slag discharge screw mechanism 3 and a connecting pipe 4 for connecting the sampling tank 1 and the pre-processing mechanism 2. See figure 1 , 2 As shown, the sampling tank 1 of the present invention includes a tank body 1-5, a grid plate 1-3 and an agitator 1-2, and the effective volume of the sampling tank 1 can be 1.5m 3 Left and right, the effective volume of the sampling tank 1 can be set according to production requirements. See figure 1 As shown, at least two layers of the present invention are provided with grating plates 1-3 with openings 1-31, which are detachably installed on the top of the tank body 1-5, and multiple supports 1-3 can be provided on the tank body 1-5. 4. The support is used to install each grid plate 1-3, and the grid plate 1-3 can be installed on the support 1-4 through f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com