A comprehensive performance test device and test method for high-temperature cascade phase change heat storage equipment

A phase-change heat storage and equipment integration technology, which is applied in the field of high-temperature cascade phase-change heat storage equipment comprehensive performance test equipment, can solve the problems of small temperature range, less phase-change heat storage equipment, phase separation, etc., and achieve compact structure and guarantee The effect of testing the consistency of working conditions and improving the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

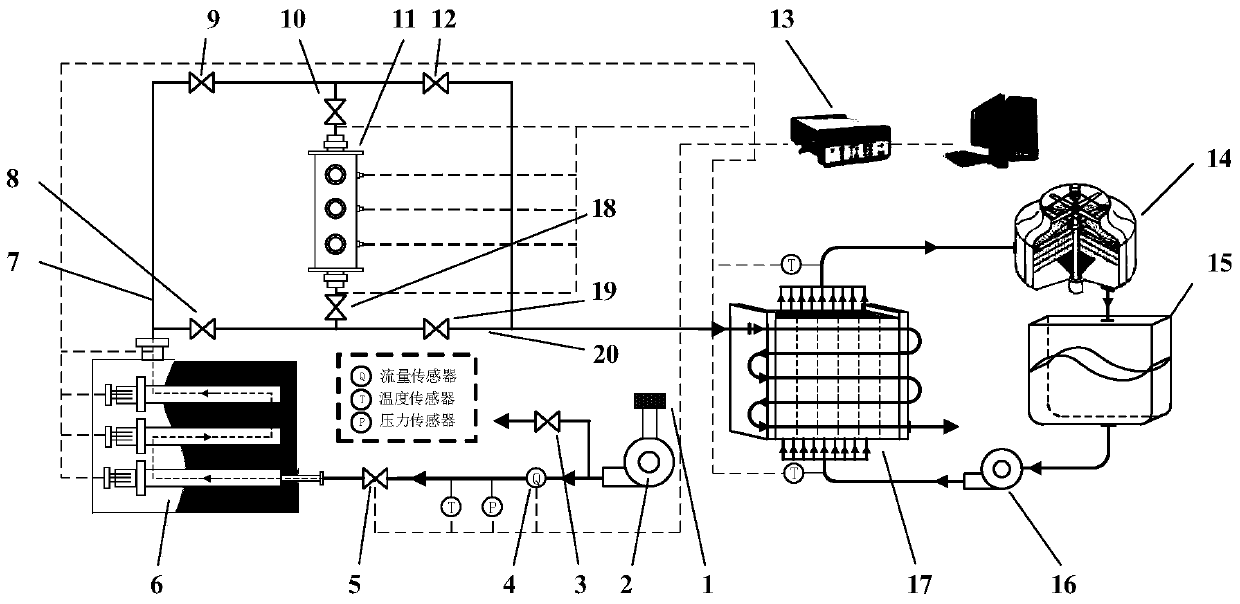

[0032] see figure 1 , the device of the present invention includes a high-temperature air delivery system, an air cooling system, and a data acquisition and control system 13 connected to the phase change thermal storage device 11;

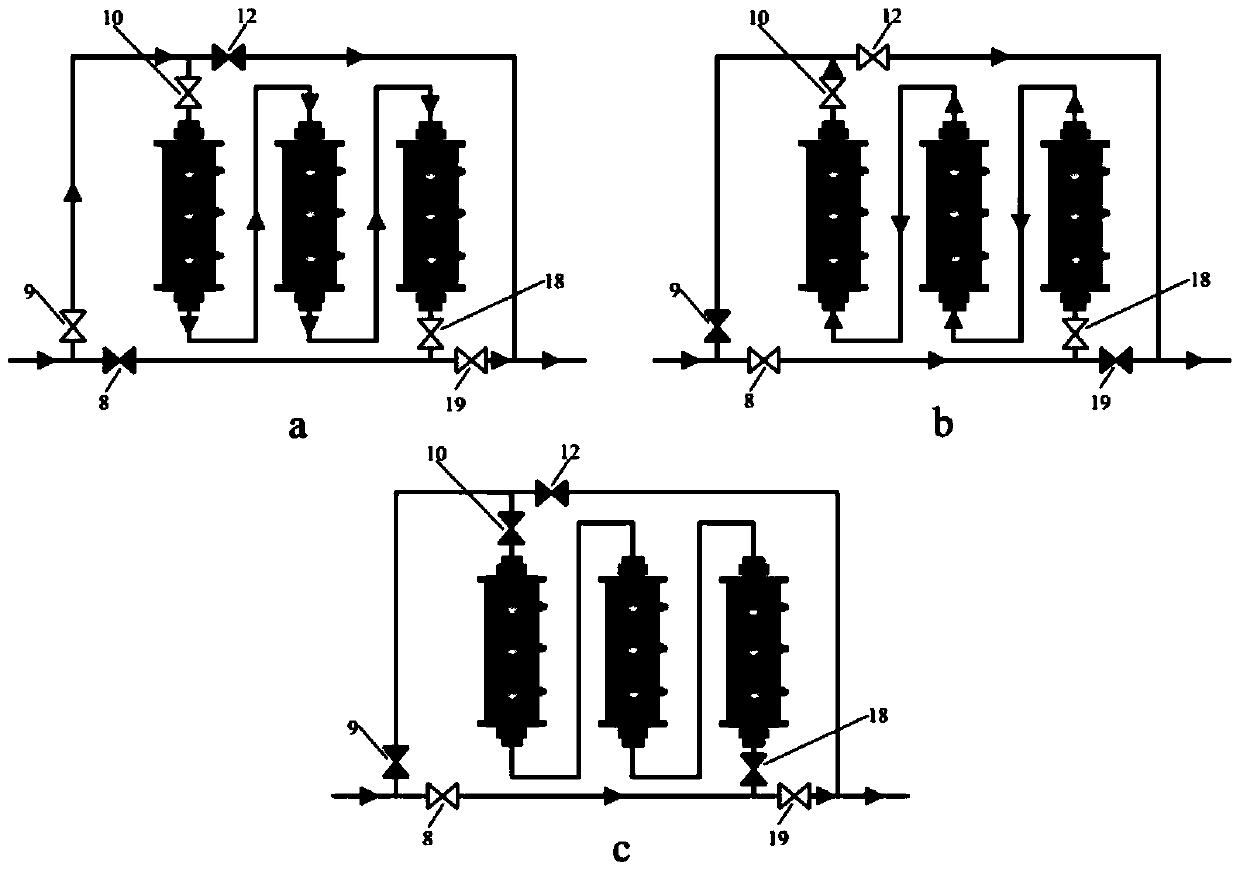

[0033] The phase change heat storage device 11 is a series cascade heat storage structure of one or two to three groups connected end to end, and the temperature sensor and pressure sensor connected to the data acquisition control system 13 are arranged inside the phase change heat storage device 11 ;

[0034] The high-temperature air delivery system includes a fan 2 with a filter 1 installed at the inlet, and the outlet of the fan (2) is respectively connected to the exhaust pipeline and the intake pipeline through a three-way pipe joint, wherein an exhaust valve 3 is installed on the exhaust pipeline , the intake pipeline is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com