Virtual and actual combined sewage treatment plant test bed and construction method thereof

A technology for sewage treatment plants and sewage treatment. It is applied in educational appliances, instruments, teaching models, etc. It can solve the problems that the test bed cannot display the process parameters of the industrial process, cannot fully display the physical simulation, and the sand table model has less interaction, so as to achieve flexibility. No hardware wiring, improved display, good intuition and dynamic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

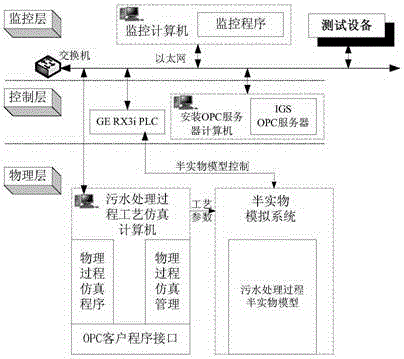

[0034] The overall structure of the present embodiment test bed is as follows figure 1 shown. The system includes physical layer, control layer and monitoring layer, which belongs to the typical layered structure of industrial control system. Among them, the physical layer adopts sewage treatment Matlab model and semi-physical model; the control layer adopts GE RX3i programmable controller, and the monitoring layer adopts KingScada configuration software. The controller and monitoring computer are connected through Ethernet, and the test equipment is also connected to Ethernet to realize the attack test on the test bed. In this system, data communication is the key. The unit of data communication mainly includes Matlab simulation program, man-machine interface and PLC. Adopt GE's IGSOPC server.

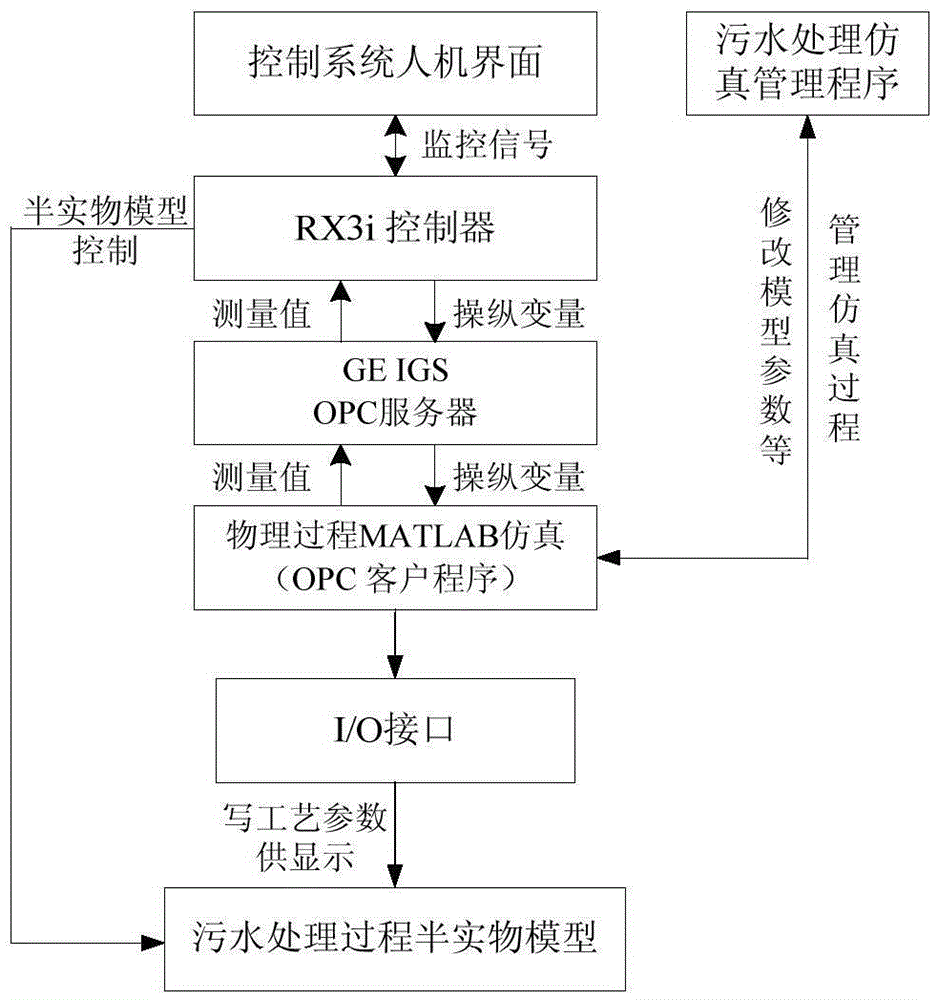

[0035] The information flow of the whole system is as figure 2 shown. The process measurement parameters of the Matlab simulation are related to the measurement input of the PI...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com