Preparation method for hairy crab flavor salty ice cream and products thereof

A hairy crab and flavor technology, which is applied in frozen desserts, food science, applications, etc., can solve the problems of poor taste, flavor, appearance, tissue coagulation, low solid content, high salt content, etc., to achieve rich product diversification and low preparation cost , The effect of simple preparation and processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

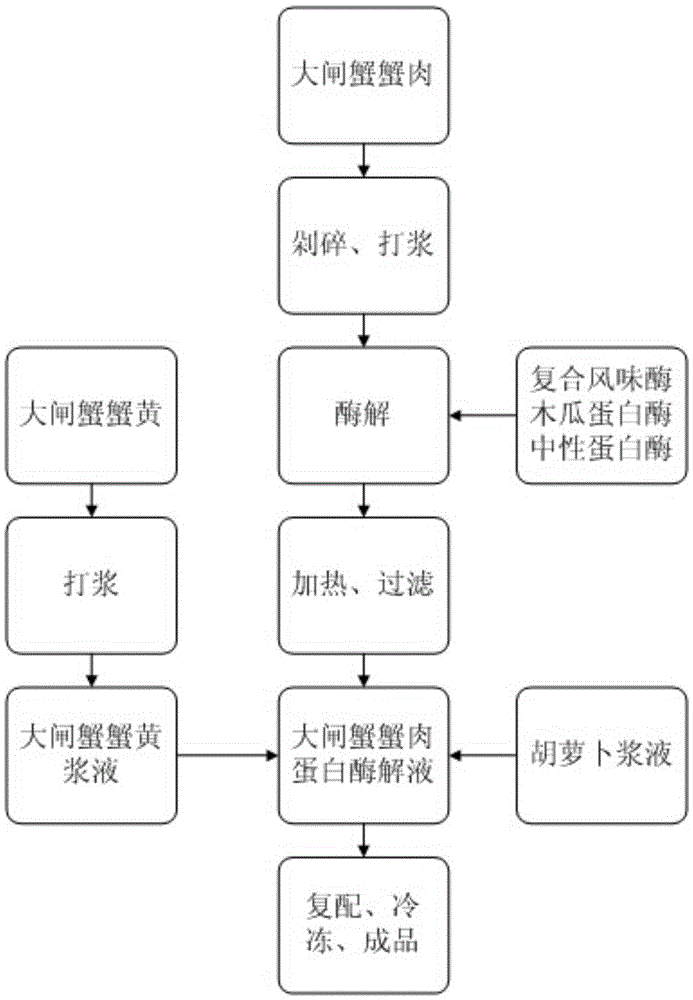

[0042] A preparation method of hairy crab flavor salty ice cream, comprising the following steps:

[0043] Step 1: Prepare crab roe slurry:

[0044] Steam the fresh female hairy crabs and separate the crab meat and crab roe;

[0045] adding distilled water 4 times the weight of hairy crab roe to hairy crab roe, beating and filtering to obtain hairy crab roe slurry;

[0046] Step 2: Prepare hairy crab meat protein enzymatic hydrolyzate:

[0047] After chopping the hairy crab meat, adding distilled water 7 times the weight of the hairy crab meat to make a beating to obtain a hairy crab beating liquid;

[0048] Add compound flavor enzyme, papain and neutral protease to hairy crab meat beating liquid, the added amount is 0.5g / L, 0.2g / L, 0.4g / L respectively, enzymolysis in constant temperature water bath, and filter to obtain hairy crab meat enzyme Solution;

[0049] stirring and heating the enzymatic hydrolyzate of hairy crab meat in a water bath at 95°C for 15 minutes, and th...

Embodiment 2

[0055] A preparation method of hairy crab flavor salty ice cream, comprising the following steps:

[0056] Step 1: Prepare crab roe slurry:

[0057] Steam the fresh female hairy crabs and separate the crab meat and crab roe;

[0058] adding distilled water 5 times the weight of hairy crab roe to hairy crab roe, beating and filtering to obtain hairy crab roe slurry;

[0059] Step 2: Prepare hairy crab meat protein enzymatic hydrolyzate:

[0060] After chopping the crab meat of hairy crabs, adding distilled water 10 times the weight of the crab meat for beating to obtain the beating liquid of hairy crabs;

[0061] Add compound flavor enzyme, papain and neutral protease to hairy crab meat beating liquid, the added amount is 0.7g / L, 0.3g / L, 0.6g / L respectively, enzymolysis in constant temperature water bath, and filter to obtain hairy crab meat enzyme Solution;

[0062] stirring and heating the enzymatic hydrolyzate of hairy crab meat in a water bath at 97°C for 20 minutes, an...

Embodiment 3

[0068] A preparation method of hairy crab flavor salty ice cream, comprising the following steps:

[0069] Step 1: Prepare crab roe slurry:

[0070] Steam the fresh female hairy crabs and separate the crab meat and crab roe;

[0071] adding distilled water 4 times the weight of hairy crab roe to hairy crab roe, beating and filtering to obtain hairy crab roe slurry;

[0072] Step 2: Prepare hairy crab meat protein enzymatic hydrolyzate:

[0073] After chopping the crab meat of hairy crabs, adding distilled water 10 times the weight of the crab meat for beating to obtain the beating liquid of hairy crabs;

[0074] Add compound flavor enzyme, papain and neutral protease to hairy crab meat beating liquid, the addition amount is 0.5g / L, 0.3g / L, 0.4g / L respectively, enzymolysis in constant temperature water bath, and filter to obtain hairy crab meat enzyme Solution;

[0075] stirring and heating the enzymatic hydrolyzate of hairy crab meat in a water bath at 97°C for 15 minutes,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com