Method for flocculating settling of scheelite beneficiation wastewater

A technology for mineral processing wastewater and scheelite, applied in mining wastewater treatment, flocculation/sedimentation water/sewage treatment, chemical instruments and methods, etc., can solve problems such as separation, inability to solidify, and low concentration, and achieve enhanced separation effects and solutions Purification problem, the effect of fast settling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Add milk of lime with a mass concentration of 10% to the scheelite mineral processing wastewater (composition shown in Table 1), adjust the pH of the mineral processing wastewater to 10, stir for 3 minutes and then let it stand for 10 minutes for destabilization; add 100 mg The chitosan (1wt% concentration) of / L stirs 3min, and the pH of stable waste water is at 9.5 and settles 30min; Add hydrochloric acid in the waste water after settling and pH is adjusted to 3.5, continue settling 10min, the supernatant liquid sampling test result that obtains As shown in Table 1;

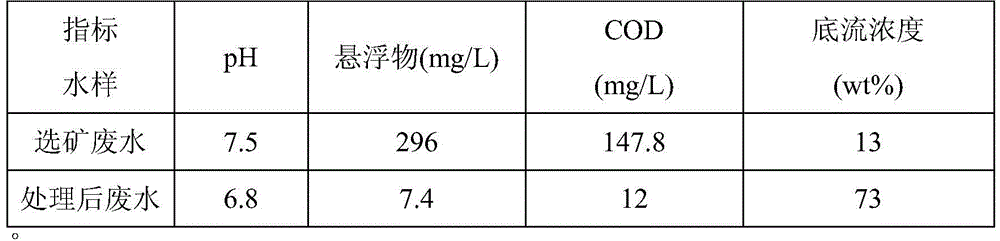

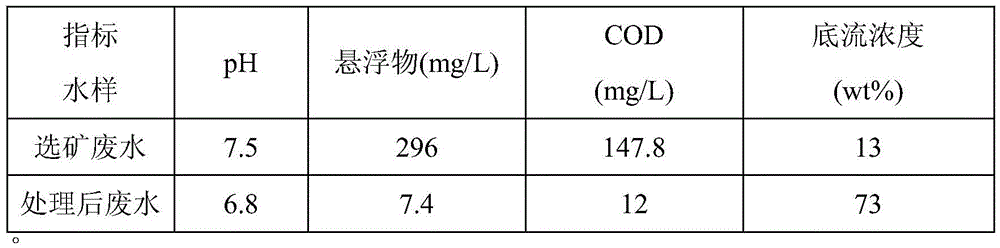

[0014] Table 1 Mineral processing wastewater and wastewater testing results after treatment

[0015]

Embodiment 2

[0017] Add lime milk with a mass concentration of 5% to the scheelite mineral processing wastewater (composition shown in Table 2), adjust the pH of the mineral processing wastewater to 9, stir for 3 minutes and then let it stand for 10 minutes to destabilize; add 80 mg of milk to the destabilizing wastewater The chitosan (1wt% concentration) of / L stirs 3min, and the pH of stable waste water is at 9 and settles 30min; Add hydrochloric acid in the waste water after settling and pH is adjusted to 3.2, continue settling 15min, the supernatant liquid sampling test result that obtains As shown in table 2.

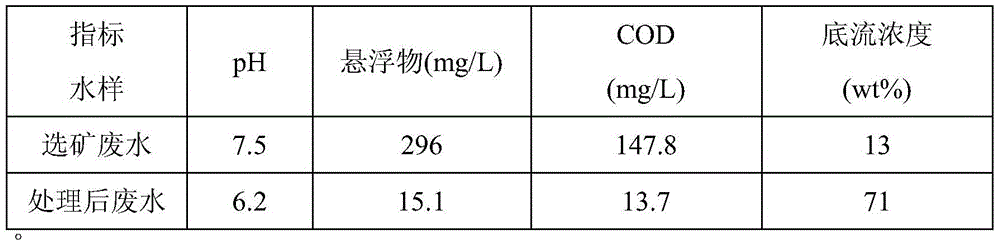

[0018] Table 2 Mineral processing wastewater and wastewater testing results after treatment

[0019]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com