High-performance magnetic rubber and preparation method thereof

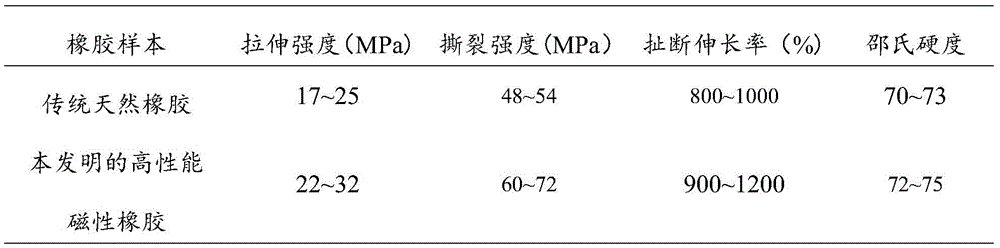

A magnetic rubber and high-performance technology, applied in the field of rubber, can solve the problems of complex drug formulation, high cost, and inability to be widely used, and achieve the effects of high surface activity, improved mechanical strength, and good soft magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The principles and features of the present invention will be described below in conjunction with specific embodiments, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0030] The present embodiment relates to a kind of high-performance magnetic rubber, comprises the raw material of following weight: Natural rubber 41.225kg, SrO 6Fe 2 o 3 5.154kg, peroxide curing agent 1.296kg, zinc oxide 2.945kg, stearic acid 0.353kg, accelerator 0.294kg, antioxidant 0.353kg, carbon black 47.114kg, plasticizer 0.353kg, paraffin 0.471kg and fatty acid 0.442kg , wherein, the peroxide vulcanizing agent is cumene hydroperoxide, the stearic acid is octadecanoic acid, the accelerator is tetramethylthiuram disulfide, the model of the antioxidant 4010NA, the model of the carbon black is N330, the particle size is 26-30nm, the model of the plasticizer is Plasthall7050, the paraffin is common industrial par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com