Method for shortening leather making soaking time

A time, lipase technology, applied in small raw hide/large raw hide/leather/fur treatment, small raw hide/large raw hide/leather hide/fur chemical treatment, material analysis by observing the effect on chemical indicators, etc. Solve the problems of water infiltration, long immersion time, etc., and achieve the effects of good pH stability, good enzyme activity, and good temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

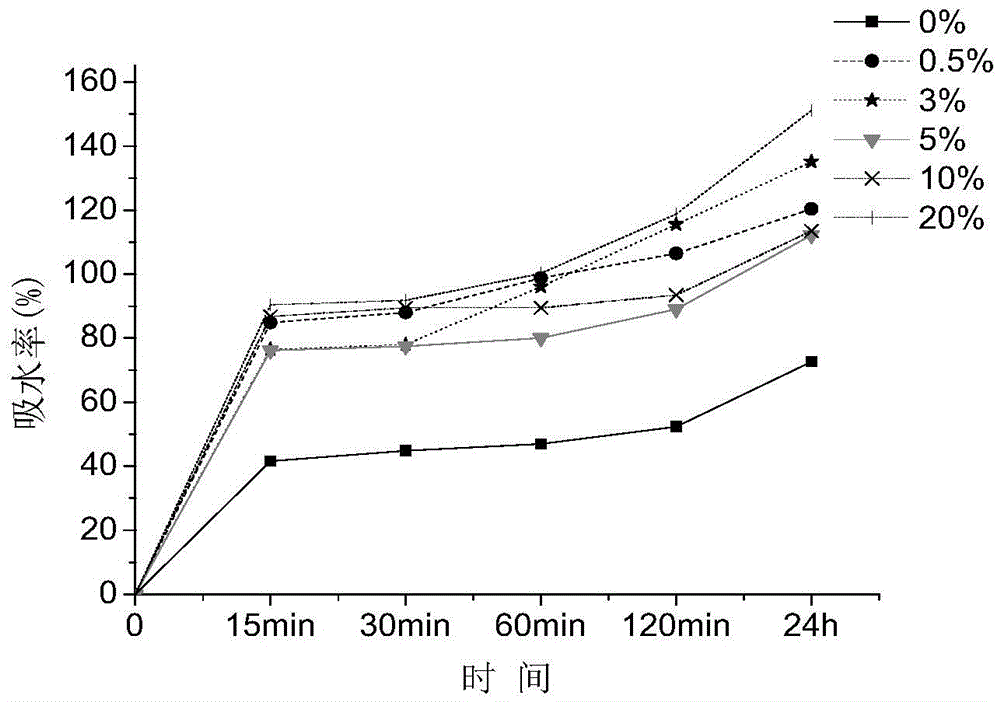

[0032] Observing the effect of CGMCCNo.11218 enzyme powder on leather immersion

[0033] As shown in Table 1, take the corresponding quality of CGMCCNo.11218 enzyme powder and place it in a Küber dish, add deionized water to keep the liquid level at the scale of 0mL, and then put skin samples into different Küber dishes, Lift the spherical end of the Kuber dish to completely return the liquid to the cylindrical end, so that the skin sample is completely immersed in the liquid, and then use plastic wrap to seal the cylindrical end to prevent moisture from evaporating. Then at 15min, 30min, 60min, 120min and 24h, lift the cylindrical end to make the liquid flow into the spherical end completely, read the scale and calculate the water absorption rate after 1min, the result is as follows figure 1 shown. It can be seen that CGMCC No.11218 enzyme powder significantly improves the water absorption rate of hides during immersion.

[0034] Table 1: The dosage of CGMCCNo.11218 enzyme ...

Embodiment 2

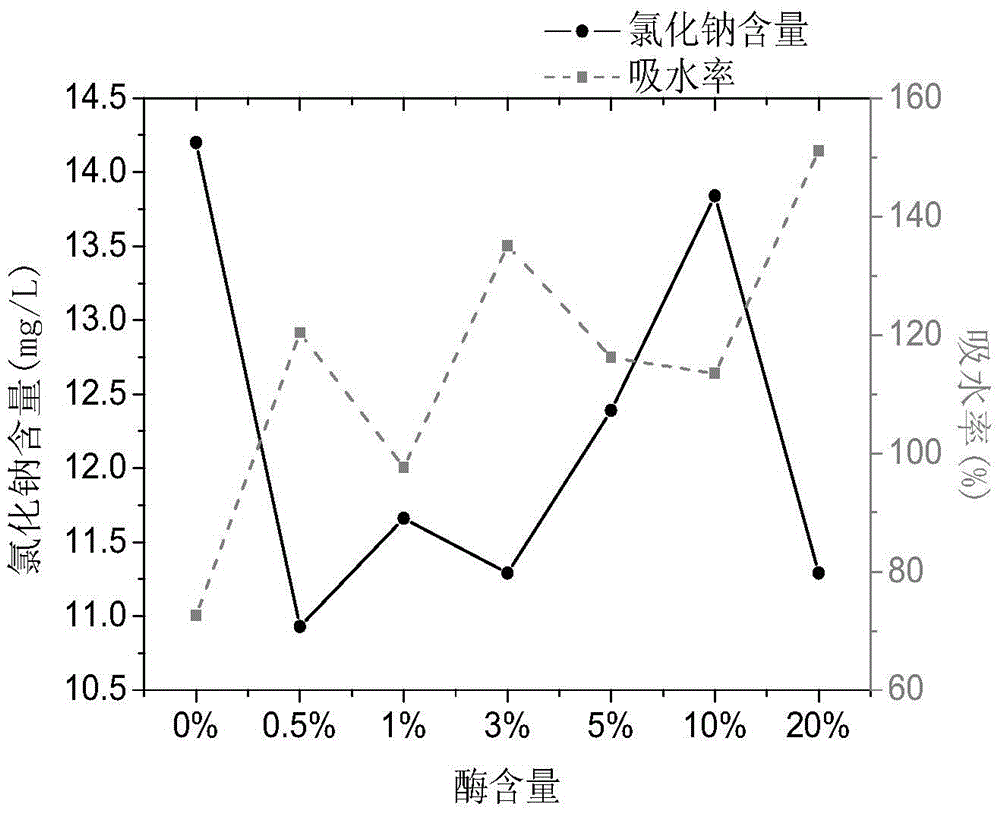

[0037] The relationship between NaCl action and GMCC No.11218 enzyme powder's effect on leather immersion

[0038] The silver nitrate solution is calibrated with the sodium chloride standard solution prepared by burning to constant weight sodium chloride. According to the calculation, the concentration of the silver nitrate standard solution is 0.1012mol / L. Draw 1ml of Example 2 and react for 24h Put it in a 150ml Erlenmeyer flask, then add 40μL of potassium chromate indicator and 10mL of deionized water, and titrate it with silver nitrate standard solution until an obvious and stable orange-red color appears as the end point, each test Two sets of parallel experiments were carried out. The calculation of chloride ion content can be seen in formula ②. The calculated unit of chloride ion content is mg / L. The result can be seen figure 2 . It can be seen that sodium chloride has a relatively obvious effect on the enzyme action on the leather soaking process, and high concent...

Embodiment 3

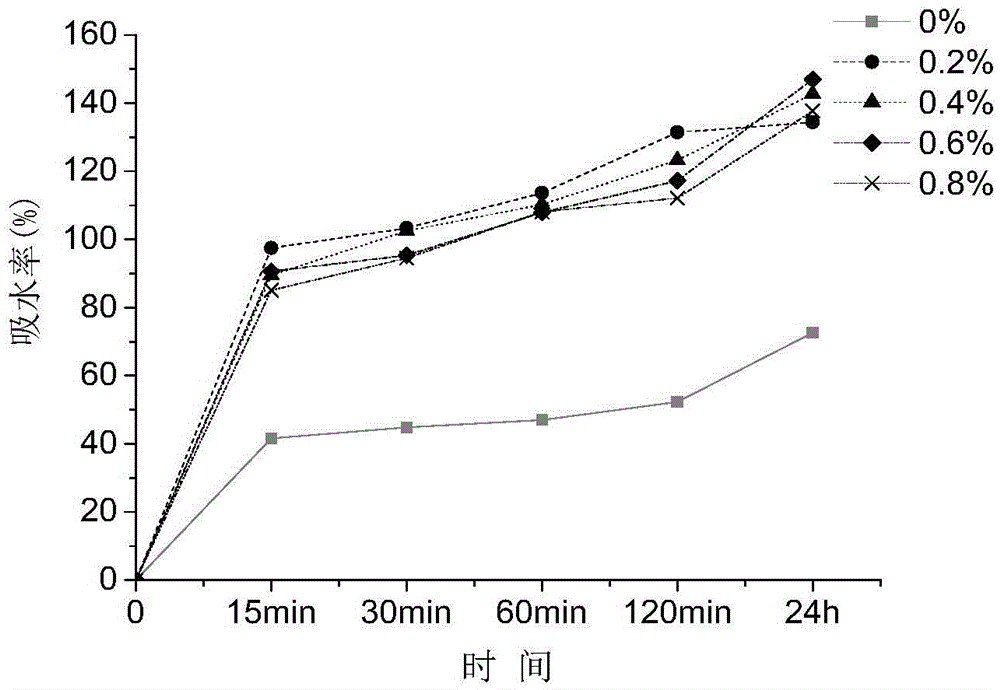

[0046] Observation of the Effect of Lipase on Water Soaking of Leather

[0047] As shown in Table 2, take lipase powder of corresponding quality and place it in a Kuber dish, add deionized water to keep the liquid level at 0mL, then put skin samples into different Kuber dishes, lift The spherical end of the Kuber dish allows the liquid to completely return to the cylindrical end, so that the skin sample is completely immersed in the liquid, and then the cylindrical end is sealed with plastic wrap to prevent moisture from evaporating. Then at 15min, 30min, 60min, 120min and 24h, lift the cylindrical end to make the liquid flow into the spherical end completely, read the scale and calculate the water absorption rate after 1min, the result is as follows image 3 shown. It can be seen that the lipase powder can obviously improve the water absorption rate of the hide during the soaking process, and the low concentration of lipase still has a very obvious improvement on the water a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com