Deepwater negative-pressure desilting system

A negative pressure, deep water technology, applied in the direction of earth mover/shovel, mechanically driven excavator/dredger, construction, etc., can solve the problems of cumbersome operation and complex structure of underwater dredger, and achieve simple construction , Overcome the effect of simple dredging equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

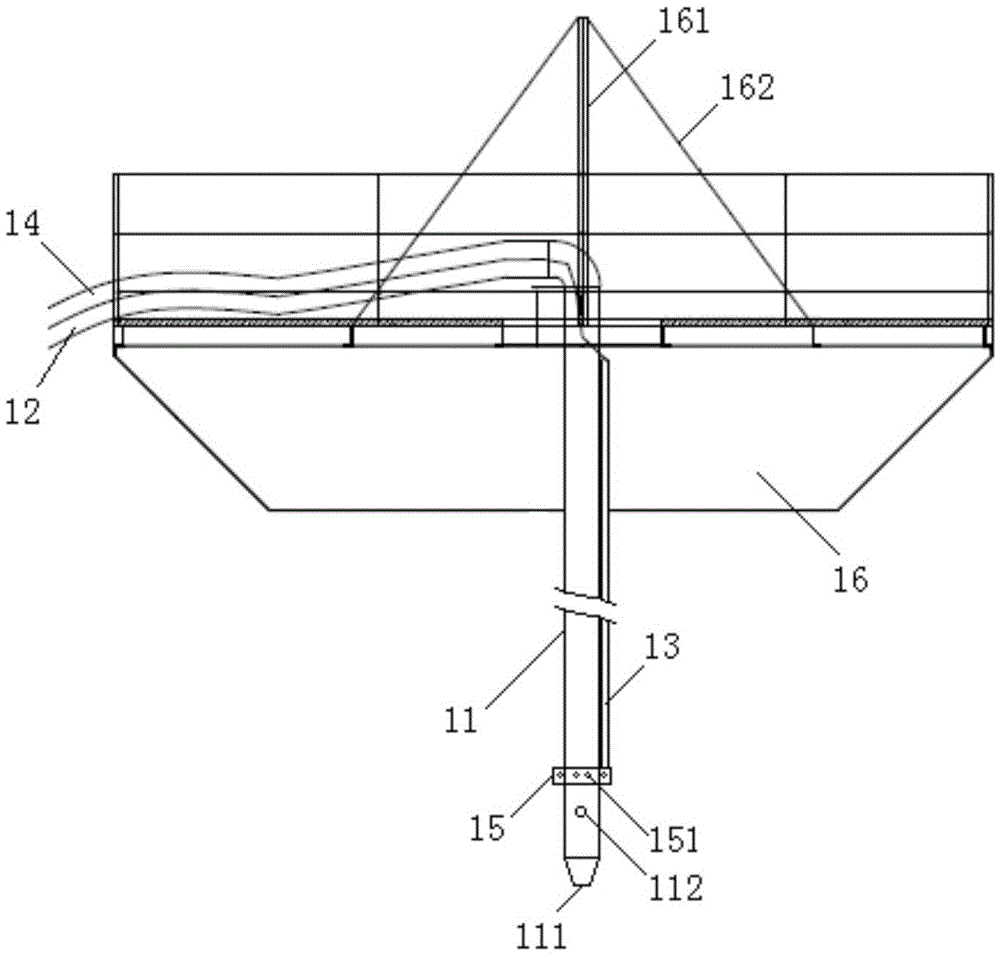

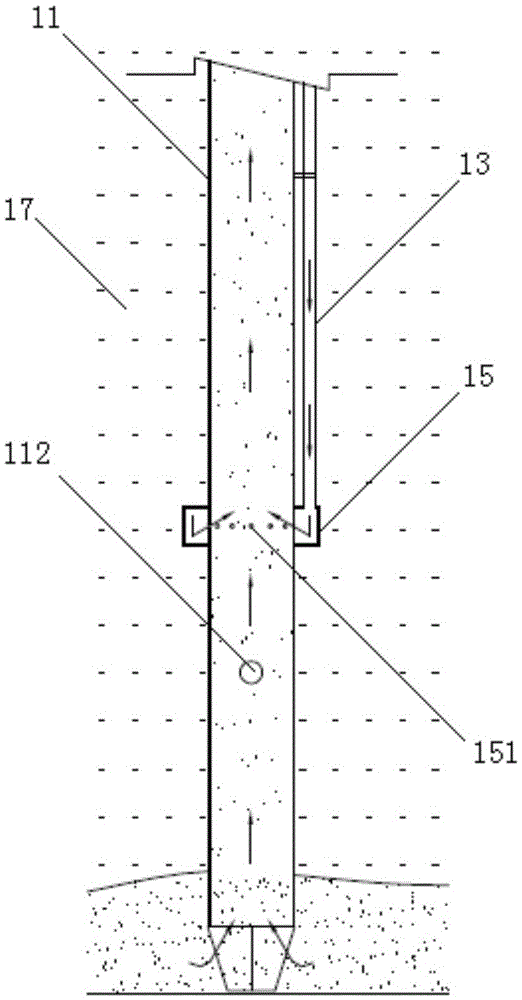

[0031] as attached figure 1 As shown, a deep water negative pressure dredging system of the present invention includes: a dredging pipe 11, the dredging pipe 11 is arranged in the water, its top is communicated with the output pipeline 12, and its bottom is arranged in the water to be cleared. Silt position; an air supply pipe 13, the air supply pipe 13 is installed on the dredging pipe 11 side, the top of the air supply pipe 13 is connected with the air compressor (not shown in the figure) through the air pipe 14, and its bottom is provided with a The air pipe 13 communicates with the air supply cylinder 15, and the air supply cylinder 15 communicates with the dredging pipe 11. In actual use, the output end of the output pipeline 12 is set in a sedimentation tank (not shown in the figure) for subsequent treatment to avoid pollution....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com