Intelligent pipeline pump

A technology of intelligent pipeline and pump shaft, applied in the direction of pump, pump control, pump device, etc., can solve the problems of large volume of frequency conversion control cabinet, aggravated environmental pollution, increased installation space, etc., to reduce manufacturing cost, reduce operating cost, reduce Small volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

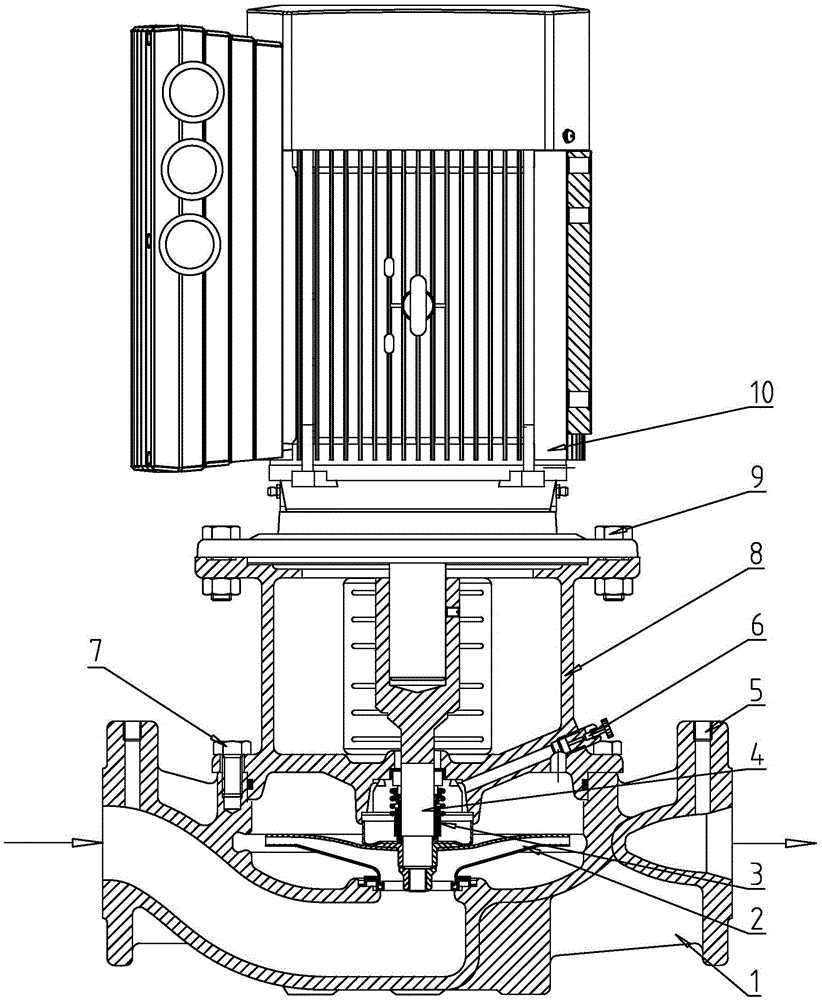

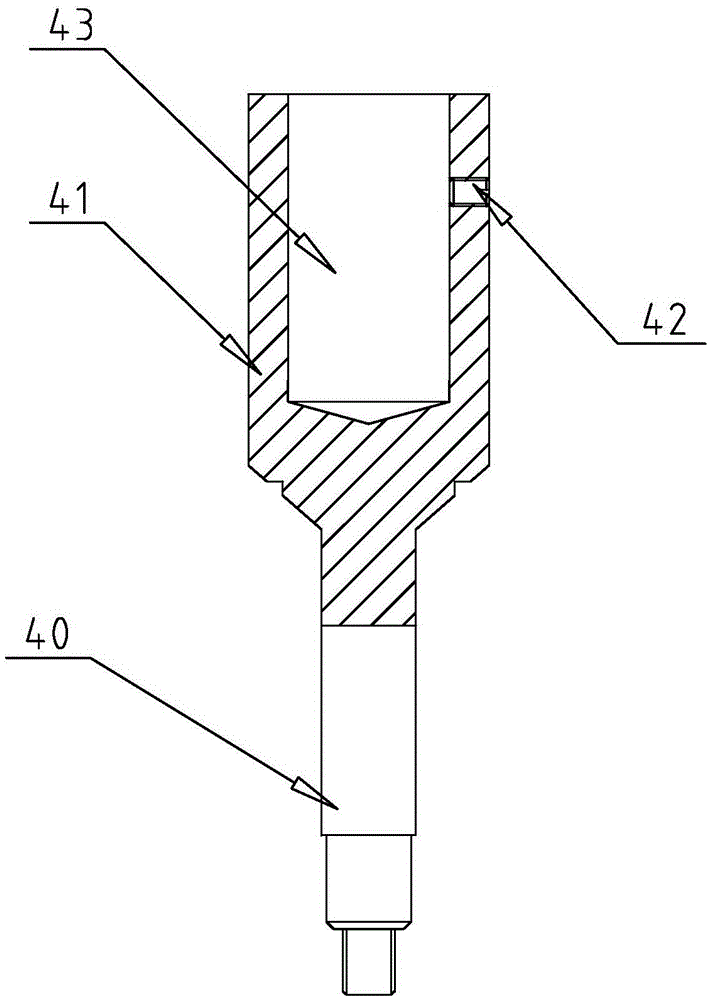

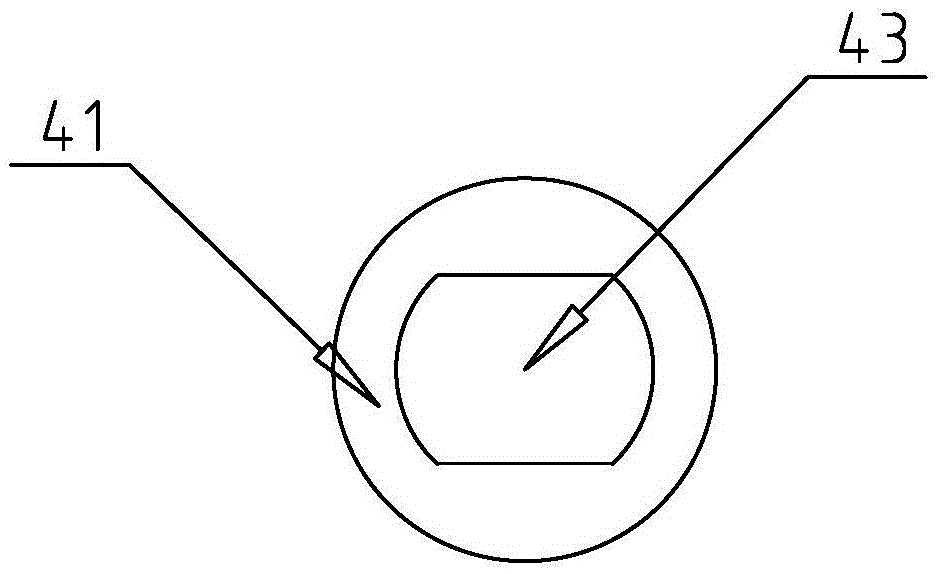

[0030] figure 1 It is a structural schematic diagram of the intelligent pipeline pump of the present invention, as figure 1 As shown, the intelligent pipeline pump of the present invention specifically includes: pump body 1, impeller 2, mechanical seal 3, pump shaft 4, sensor interface 5, exhaust hole 6, motor bracket 8, bolts connecting pump body 1 and motor bracket 8 7. The variable frequency motor 10, and the bolt 9 connecting the variable frequency motor 10 and the motor support 8.

[0031] refer to Figure 4 , the variable frequency motor 10 has a motor shaft 103, which drives the pump shaft 4 to rotate through the motor shaft 103, the pump shaft 4 transmits the power to the impeller 2, and the impeller 2 rotates to introduce the fluid through the inlet of the pump body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com