Composite Structure Double Metal Grating Polarizing Beam Splitter

A polarization beam splitter and metal grating technology, applied in diffraction gratings, instruments, optics, etc., can solve the problems of narrow working band, limitation, and reduction of polarization suppression ratio, etc., to expand the wavelength range, facilitate preparation, alleviate cycle and Paradoxical effect of slit width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

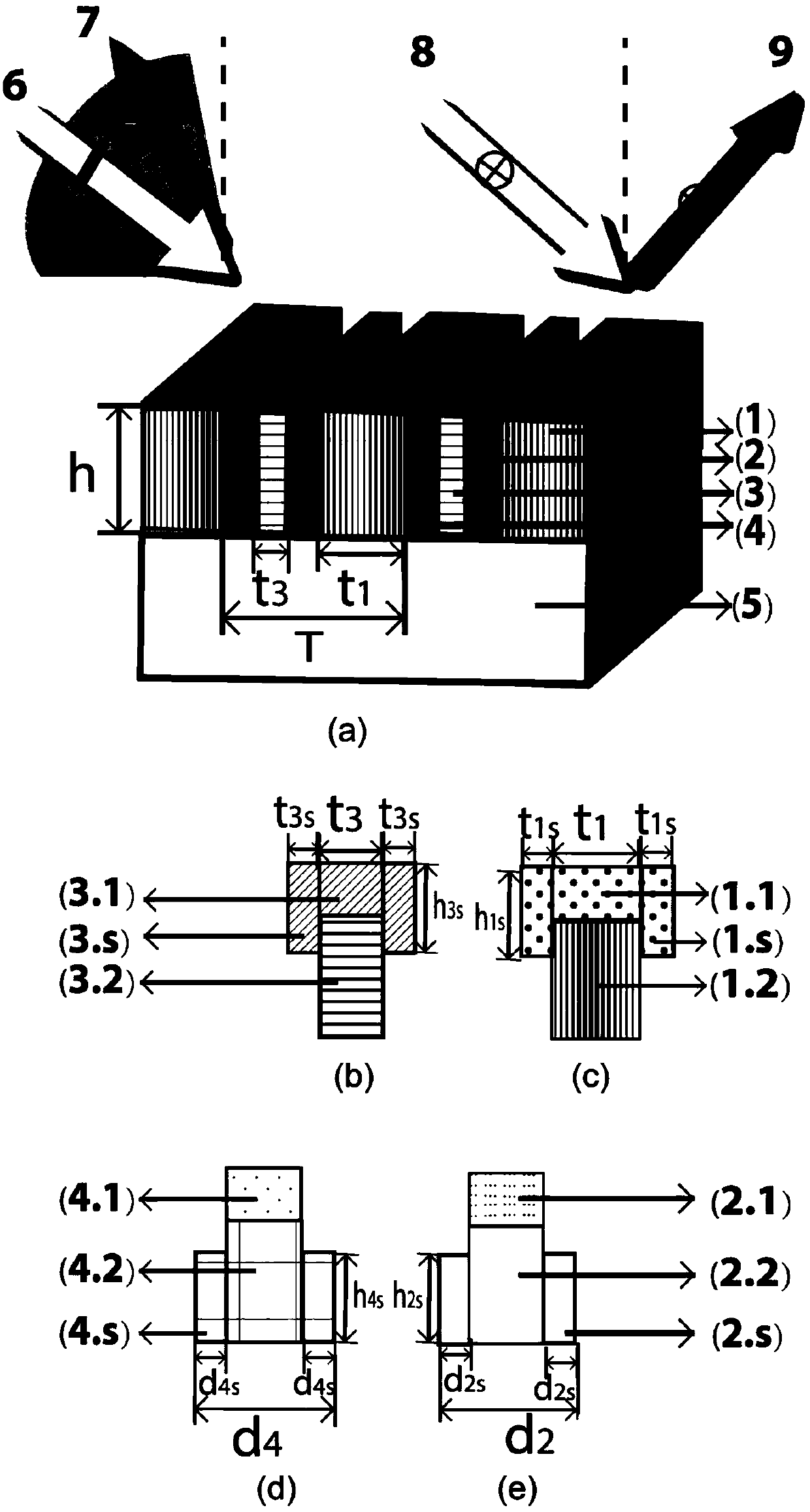

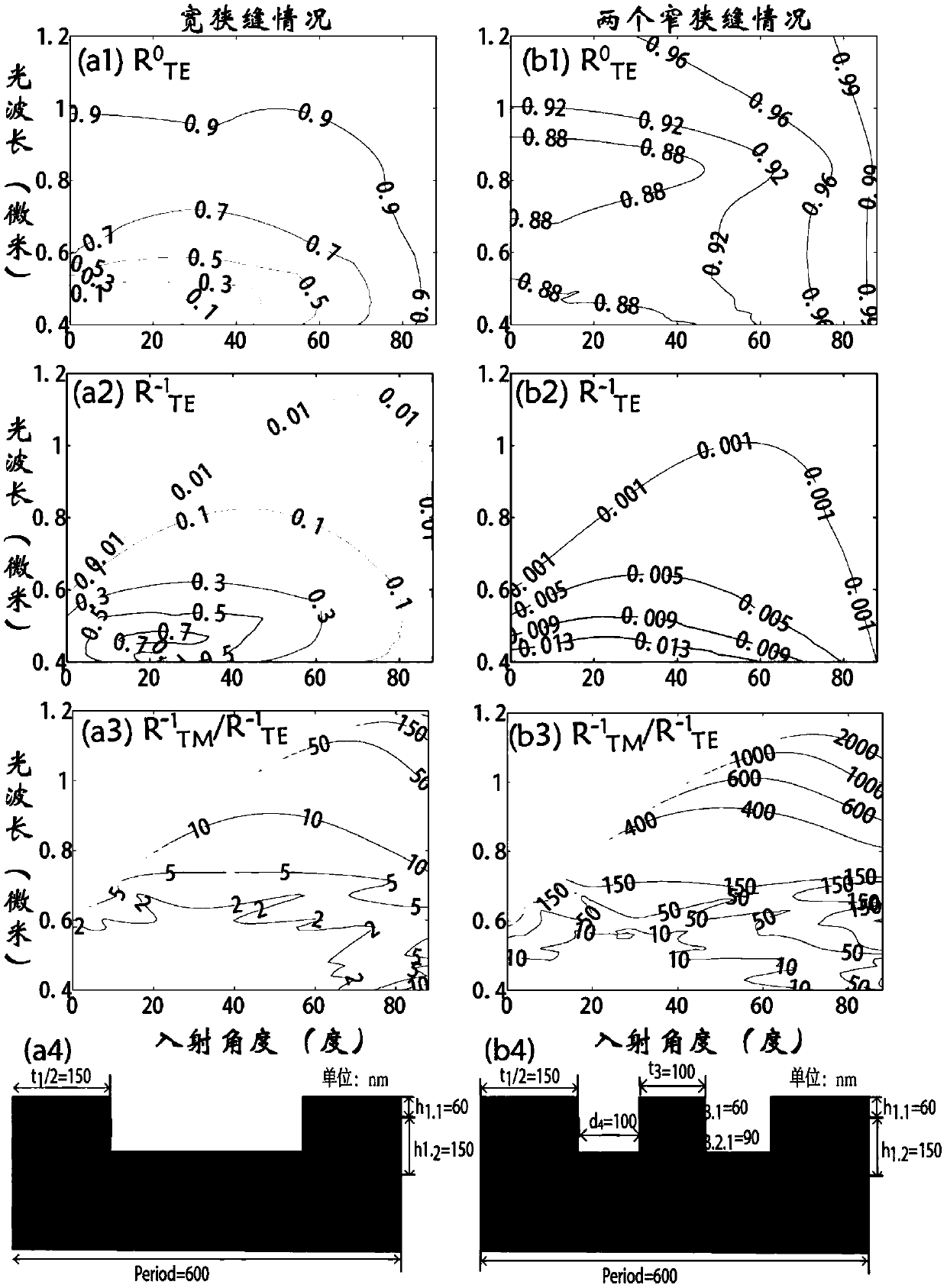

[0032] Embodiment 1: A compound structure metal grating polarization beam splitter improves the extinction ratio of back diffraction by 10-20 times. Combining the simulation results of the commercial software RSOFT and the schematic diagram of the grating structure figure 2 , and the left and right columns correspond to the case of simple and composite metal aluminum gratings, respectively. The period of the grating is 600 nanometers; the second material 2 is the same as the fourth material 4, the upper material is air with a thickness of 150 nanometers, the lower material is metal aluminum with a thickness of 60 nanometers, and the width is 100 nanometers; the first material 1 The width is half of the period, i.e. 300 nanometers, wherein the upper layer material 1.1 in the first material is an aluminum film with a thickness of 60 nanometers, and the lower layer material 1.2 in the first material is PMMA (refractive index 1.55) with a thickness of 150 nanometers; the third T...

Embodiment 2

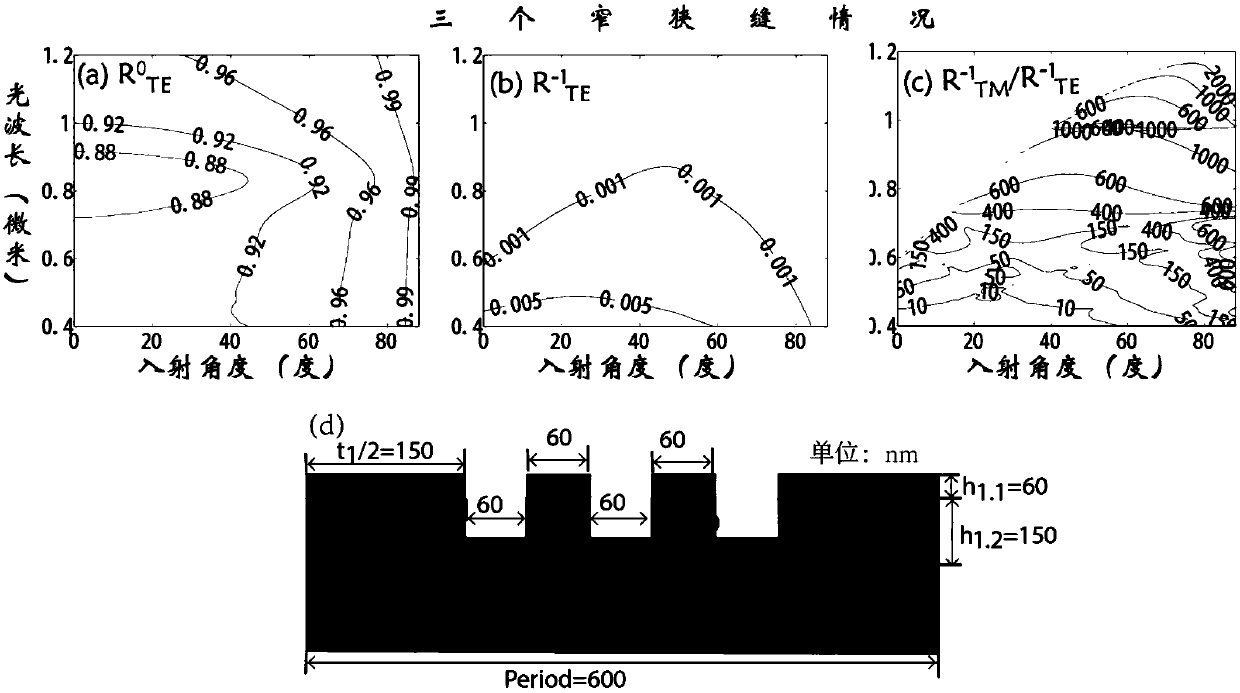

[0033]Embodiment 2: A composite structure metal grating polarization beam splitter improves the extinction ratio of back diffraction in the visible light band in a wide range of angles. Combining the simulation results of the commercial software RSOFT and the schematic diagram of the grating structure image 3 , the difference between the grating structure and embodiment 1 is that there are three slits in the grating period: the three slits are all the same, the upper layer material is air with a thickness of 150 nanometers, and the lower layer material is metal aluminum with a thickness of 60 nanometers, and its width is the same. It is 60 nanometers; the first material is the same as the first material in embodiment 1; the two kinds of materials separating the three slits are the same, and the width is 60nm, and its upper layer material is all aluminum with a thickness of 60 nanometers, and the lower layer material is all aluminum with a thickness of 60 nm. 150nm PMMA. The ...

Embodiment 3

[0034] Embodiment 3: A THz band plasmonic polarization beam splitting device using a metal grating with a composite structure, such as Figure 4 As shown, four slits are included in the grating period, and the slits are all the same, the upper layer material is air with a thickness of 2.5 microns, and the lower layer material is composed of composite metal chromium-aluminum-chromium with a thickness of 1.2 microns, and its width is 4 / 7 microns; the width of the first material is 4 microns, the upper material is composed of composite metal chromium-aluminum-chromium with a thickness of 1.2 microns, and the lower material is PMMA with a thickness of 2.5 microns; the three materials for isolating the four slits are the same , with a width of 4 / 7 microns, the upper layer material is composed of composite metal chromium-aluminum-chromium with a thickness of 1.2 microns, and the lower layer material is PMMA with a thickness of 2.5 microns. The composition of the above composite met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com