Metal grating polarizing beam splitter and its preparation method

A technology of polarizing beam splitter and metal grating, which is used in instruments, light guides, optics and other directions to achieve the effect of being suitable for mass production, good beam splitting characteristics and simple parameter design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

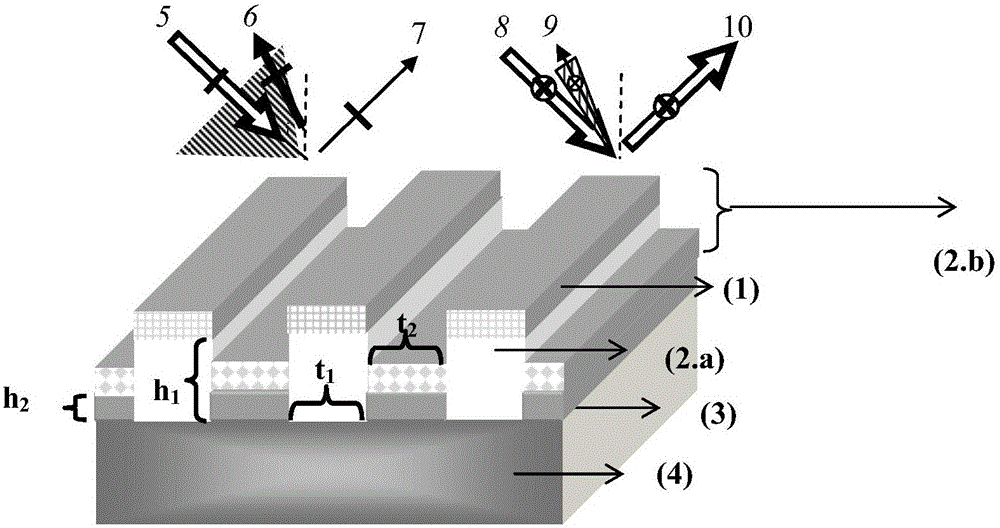

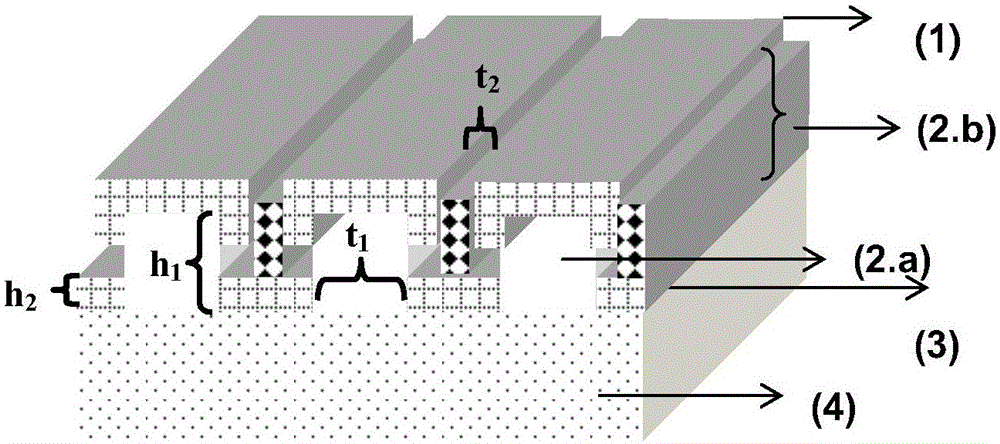

[0048] Embodiment 1: A three-channel visible light band plasma polarization beam splitting device with TM diffraction / TE reflection / TM transmission of a double-layer metal grating.

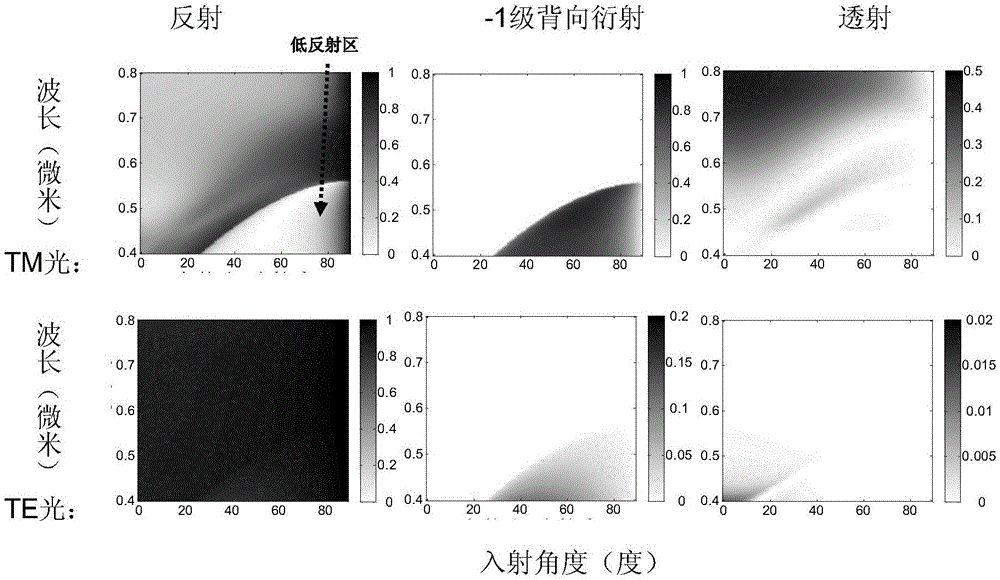

[0049] Combining simulation results with commercial software RSOFT image 3 , Reflection, diffraction and transmission spectra of a double-layer metallic aluminum grating with a grating period of 280 nm. Both the width of the first dielectric grating 2.a and the second dielectric grating 2.b are half of the period, the first dielectric grating 2.a is PMMA, the refractive index is 1.5, the second dielectric grating 2.b is air, and the thickness is 100 nanometer, the upper metal grating 1 and the lower metal grating 3 are both aluminum, and their thicknesses are both 60 nanometers. The simulation results show that almost all TE light is reflected, and part of the TE light with a wavelength shorter than 410 nm will be diffracted, and the diffraction efficiency is lower than 20%. TM light with a wav...

Embodiment 2

[0050] Example 2: A visible light band plasmonic polarization beam splitter using a double-layer metal dielectric composite grating, in figure 1 On the basis of the device structure, the upper metal grating 1 and the lower metal grating 3 are respectively covered with an anti-reflection magnesium fluoride dielectric layer with a thickness of 10 nm and a refractive index of 1.2. Reflection, diffraction and transmission spectra obtained from RSOFT simulations, see Figure 4 , the abscissa of the figure is the incident angle, and the unit is degree. The ordinate is the wavelength of the incident light, and the unit is micron. It can be seen from the figure that the reflection of TM is reduced, especially the long-wavelength band reflection is reduced from 10% to 1% at most; at the same time, the transmission is enhanced to 60%, and some wavelengths are increased by five or six times; the diffraction is also enhanced. The spectrum of TE light does not change much. It can be see...

Embodiment 3

[0051] Embodiment 3: A THz band plasmonic polarization beam splitting device using a double-layer composite metal grating, the width of the first dielectric grating 2.a and the second dielectric grating 2.b are both half of the period, and the first dielectric grating 2. .a is PMMA (refractive index 1.5), the thickness is 2.5 microns, combined with the attached Figure 5 , Reflection, diffraction, and transmission spectra of a double-layer composite metal grating with a grating period of 8 μm. The duty ratio of the dielectric grating is 0.5, and the thickness of the medium is 25 microns. Each layer of composite metal grating 1 and 3 is composed of chromium-aluminum-chromium, the thickness of aluminum is 1.2 microns, and the thickness of chromium is 10 nanometers. The upper and lower layers of composite metal grating have the same structure. The role of chromium is to increase the adhesion of metals and media. Simulation results show that the composite metal grating can be us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com