A reflective asymmetric metal grating polarizing beam splitter

A polarization beam splitter, metal grating technology, applied in diffraction grating, instruments, optics, etc., to achieve the effect of being suitable for mass production, simple parameter design, and reducing reflection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

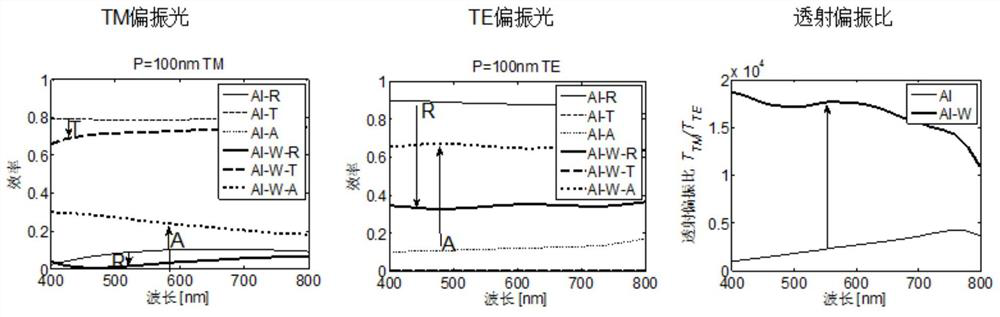

[0063] One-dimensional aluminum-tungsten grating. When the light is incident from the grating surface, the reflection of TE light is suppressed; when the light is incident from the substrate surface, the TE light is highly reflective. At the same time all have the same, high transmission polarization suppression ratio.

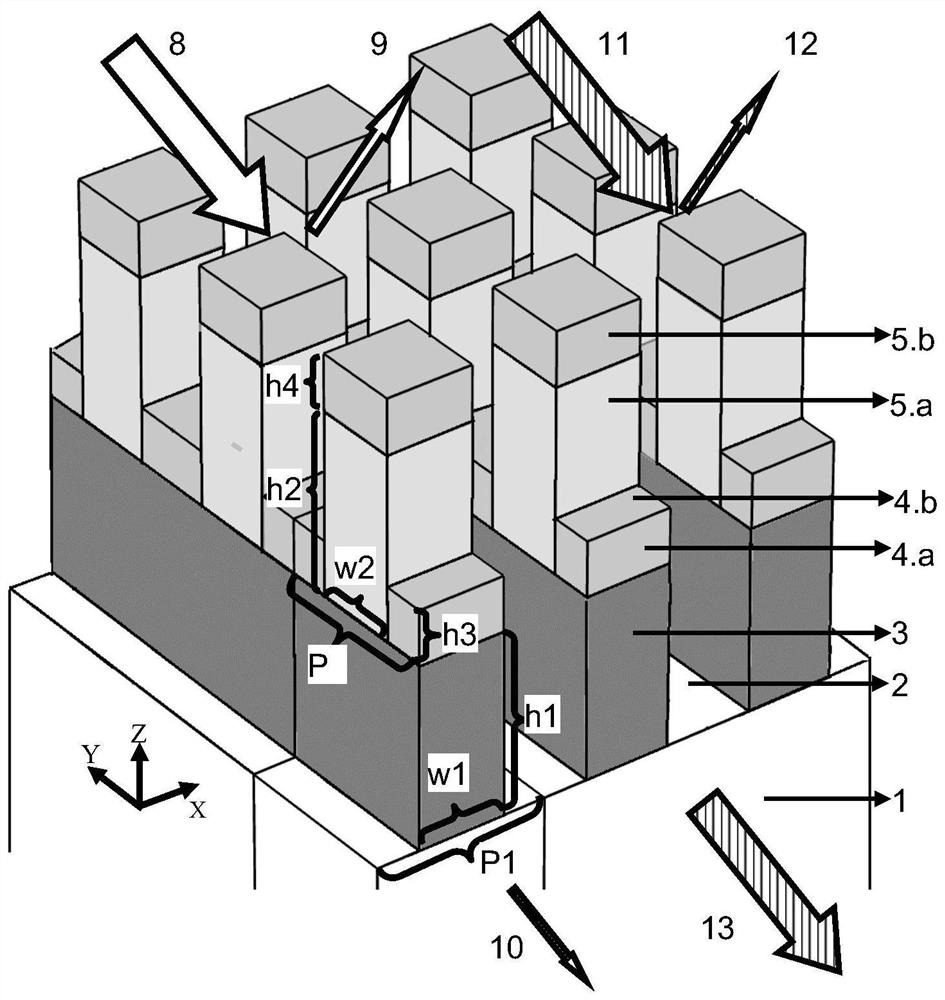

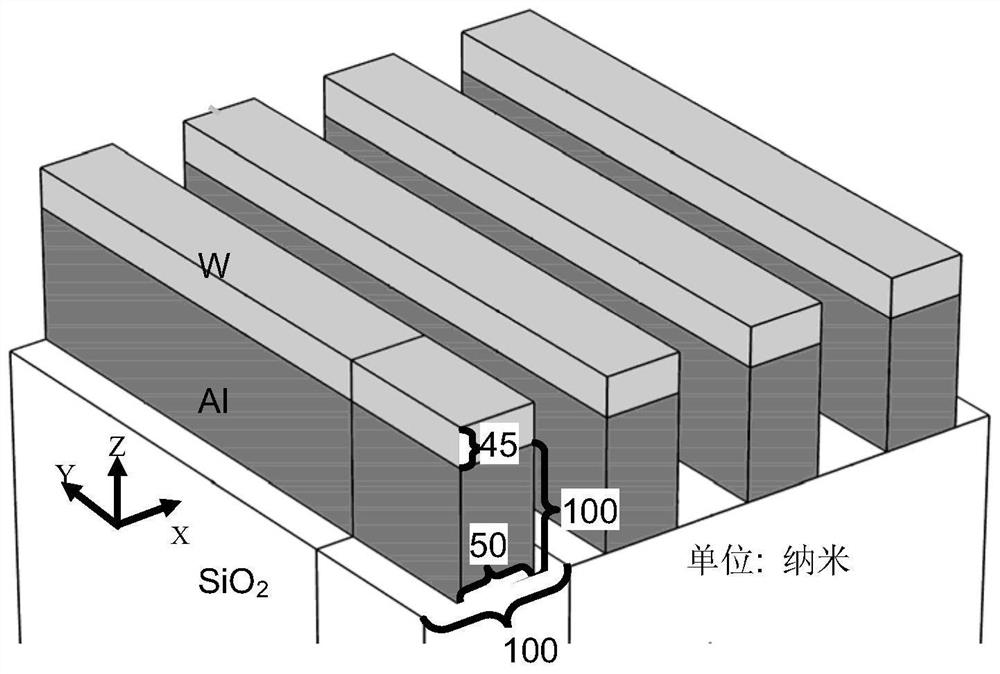

[0064] attached Figure 2 ~ Figure 4 A schematic diagram of the one-dimensional aluminum-tungsten grating structure and the reflection, transmission and absorption spectra in the visible range obtained by using the commercial software COMSOL, as well as the simulation results of the transmission polarization ratio are shown. The lower layer of the polarizing beam splitter is the first metal aluminum and the first medium (a material transparent to incident light or transparent to the working wavelength, such as air, pmma (polymethyl methacrylate), SiO2 (silicon dioxide), The first grating made of PC (polycarbonate), quartz, or PET (polyester resin), the perio...

Embodiment 2

[0068] see Figure 5 and Figure 6 , on the basis of Example 1, the thickness of the aluminum is increased to 150 nanometers, and at the same time, there is a side wall 6 of the first light-absorbing material with a thickness of 5 nanometers on the edge of the aluminum strip, and the side wall 6 of the first light-absorbing material is made of metal tungsten.

[0069] attached Figure 5 A schematic diagram of the composite grating structure is shown, and its structural parameters are the same as the one-dimensional aluminum-tungsten grating in Example 1, except that the thickness of the aluminum layer grating is increased to 150 nanometers, and the aluminum strips have 5 nanometer tungsten sidewalls.

[0070] attached Figure 6 The results of a simulated embodiment using the commercial software COMSOL are shown, with light incident from a grating facet. The simulation results show that the increase of the thickness of the aluminum layer has little effect on the reflection a...

Embodiment 3

[0072] see Figure 7 and Figure 8 , one-dimensional aluminum-boron carbide grating, the light is incident from the grating surface, the reflection of TE light is suppressed, and it has a high transmission polarization suppression ratio.

[0073] attached Figure 7 A schematic diagram showing the structure of a one-dimensional aluminum-boron carbide grating. The lower layer of the polarizing beam splitter is the first grating composed of the first metal aluminum and the first medium (air, pmma or SiO2). The period direction of the grating is along the x-axis, and the aluminum The lines extend along the y-axis direction with a period of P1 = 100 nanometers, the width of the metal aluminum lines is half of the period, ie w1 = 50 nanometers, and the aluminum thickness h1 = 120 nanometers. The first material above the aluminum is boron carbide with a thickness h2 = 60 nm.

[0074] Figure 8The reflection, transmission and absorption spectra in the visible range obtained by usi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com