Turnover equipment, turnaround method, and solar cell production line

A production line and equipment technology, applied in the field of solar cells, can solve the problems of conveyor device failure, scrapped glass trays, and the inability of conveyor devices to effectively sense the position of the lifting platform, so as to avoid loss and reset, improve production efficiency, and ensure consistency. Effects of Sex and Continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

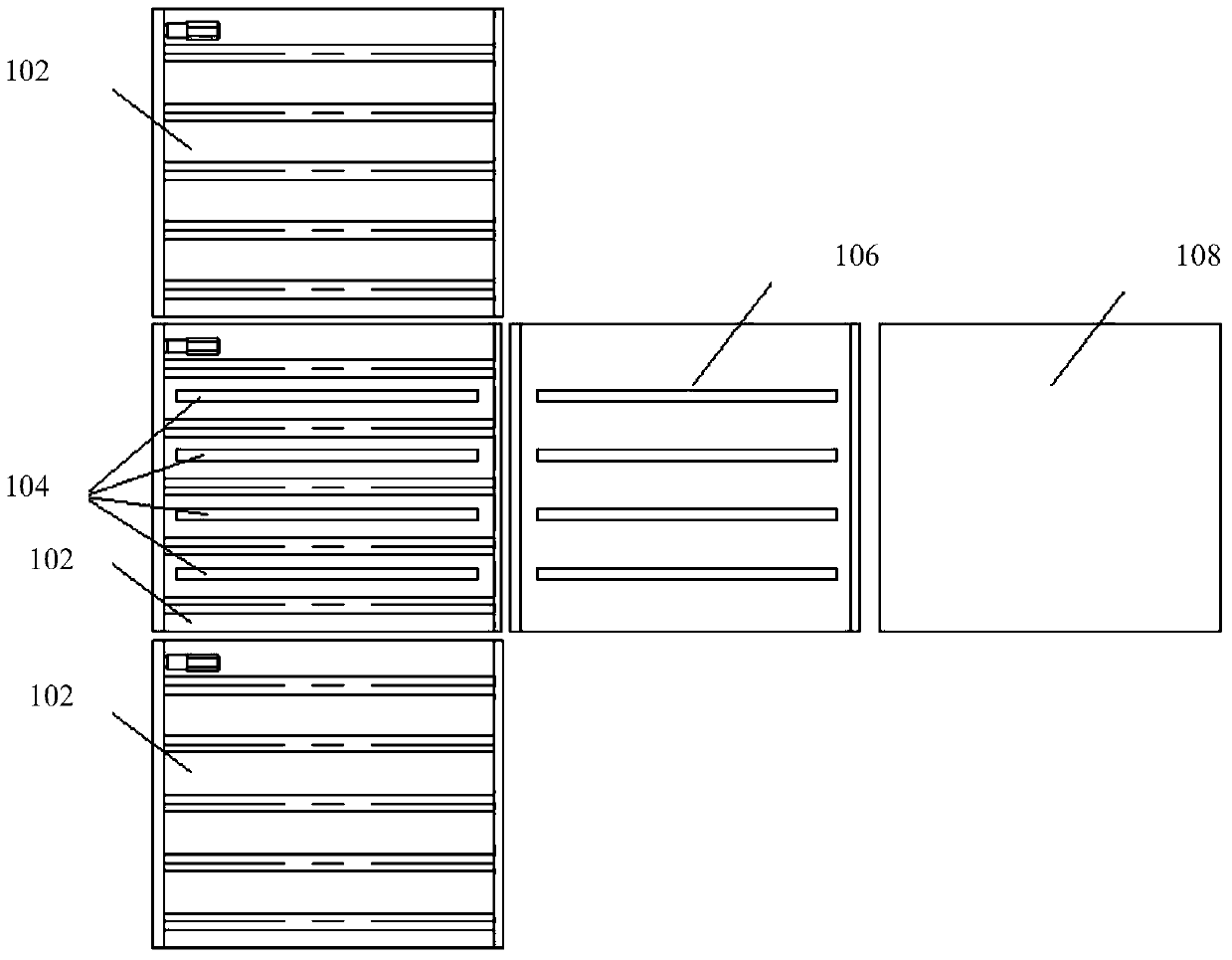

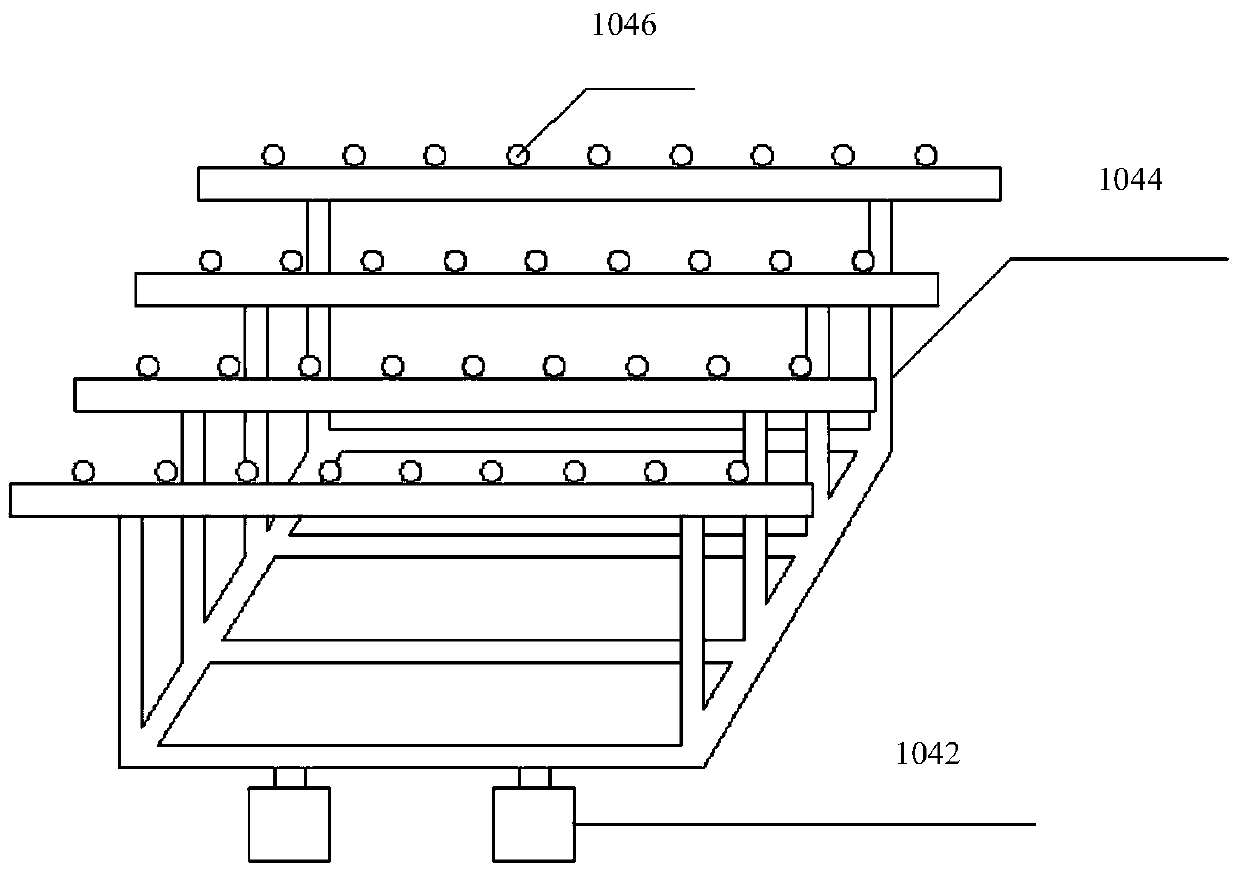

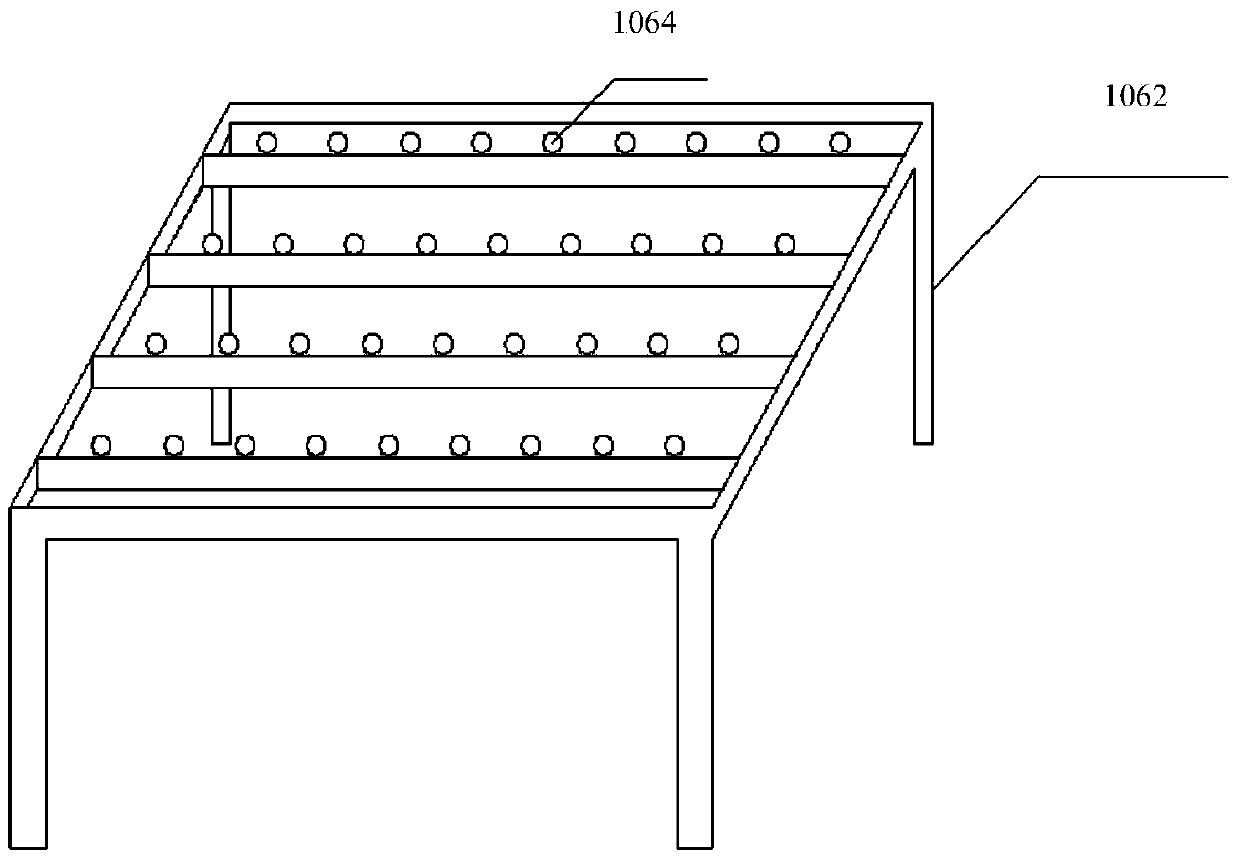

[0039] The specific implementations of a turnaround equipment, a turnaround method and a solar cell production line provided by the embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0040] A turnover equipment provided by an embodiment of the present invention includes: a signal acquisition device, a turnover device, and a control device; Control device; the control device is used to stop the operation of the conveying device when it is determined that the running position of the to-be-turned object coincides with the designated position on the conveying device, and start the turnover device, and place the to-be-turned object between the conveying device and the sheeting device Carry out turnover; wherein, the specified position is the position where the vertical projection of the turnover device is located on the conveying device.

[0041] In the turnover equipment provided by the embodiment of the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com