Organic light-emitting diode and fabrication method thereof and organic light-emitting diode display panel

A technology of light-emitting diodes and manufacturing methods, applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve problems such as reducing luminous efficiency, affecting device luminous efficiency and life, and electron and hole imbalance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In the following description, for purposes of illustration rather than limitation, specific details, such as specific system architectures, interfaces, and techniques, are set forth in order to provide a thorough understanding of the present invention.

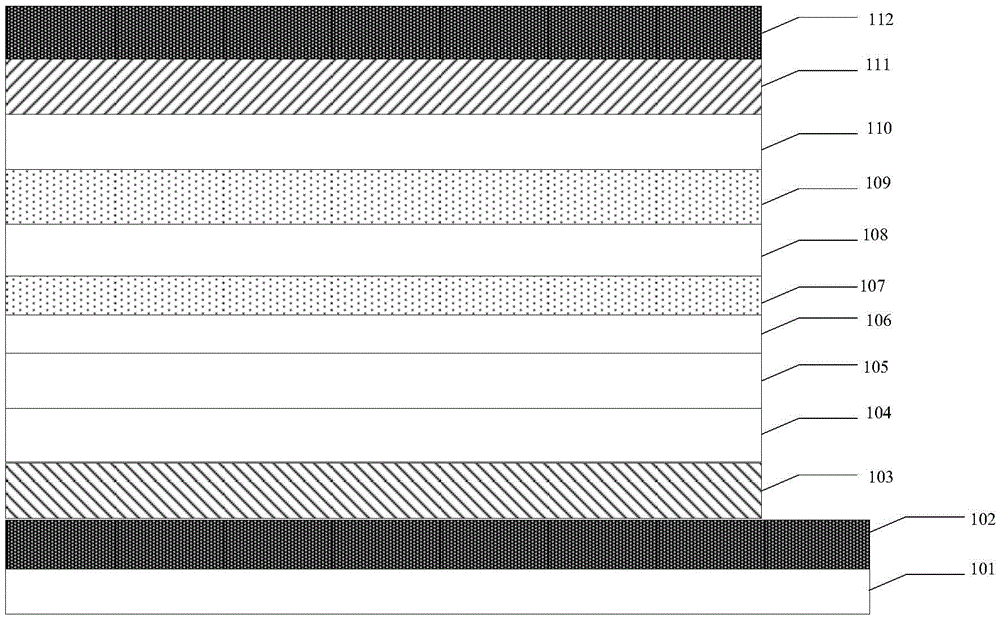

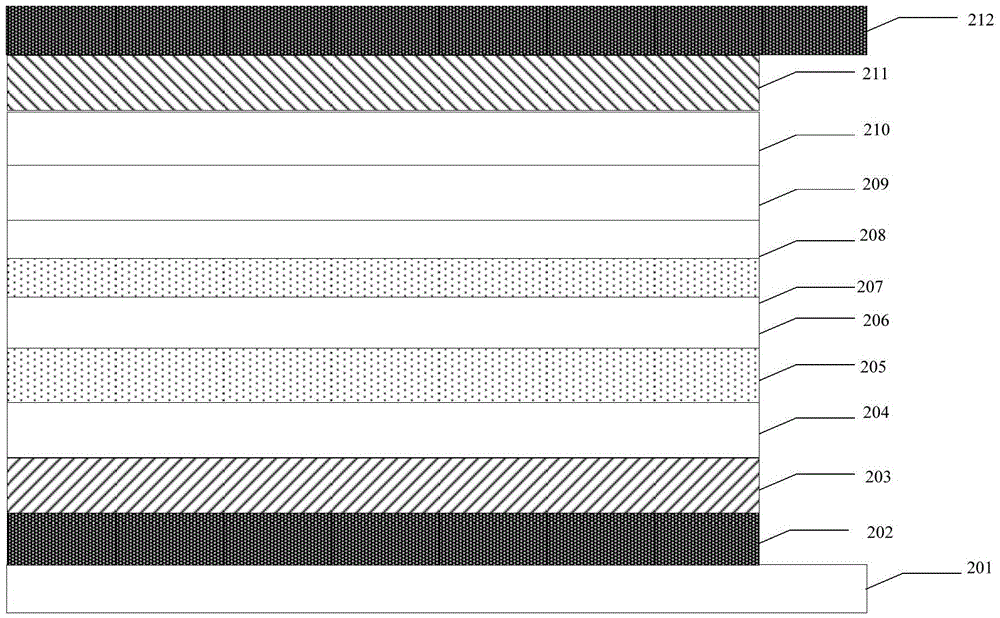

[0019] see figure 1 , figure 1 It is a schematic cross-sectional structure diagram of an embodiment of the organic light emitting diode of the present invention.

[0020] Such as figure 1 As shown, the organic light-emitting diode (OLED) in this embodiment includes a glass substrate 101, an anode metal layer 102 stacked on the glass substrate 101, a hole injection layer 103, a hole transport layer 104, an electron Blocking layer 105 , first light emitting layer 106 , second hole blocking layer 107 , second light emitting layer 108 , first hole blocking layer 109 , electron transport layer 110 , electron injection layer 111 , cathode metal layer 112 .

[0021] Wherein, the second hole blocking layer 107 is arranged be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com