Lubricating oil composition for metal working

A lubricating oil composition and metal processing technology, applied in the direction of lubricating compositions, additives, petroleum industry, etc., can solve the problems of reduced processing accuracy, tool damage, material fracture, etc., and achieve excellent processing performance and less environmental problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 and comparative example 1

[0115] Table 1 shows the compounding amounts and properties of various lubricating base oils and additives. The added amount (% by mass) of each additive is based on the total amount of the lubricating oil composition. For each of the obtained compositions, processability was evaluated by a tapping test.

[0116] (a1) Di-t-octyl polysulfide (sulfur content: 33.5% by mass, ratio of sulfur bridging number 4 or more: 35 mol%), (a2) di-t-octyl polysulfide (sulfur content: 31% by mass , the presence ratio of 4 or more sulfur bridging numbers: 15 mol %) and (a3) di-t-octyl polysulfide (sulfur content: 20 mass %, the presence ratio of 4 or more sulfur bridging numbers: 35 mol %) are commercially available sale.

[0117] (A1-1) Di-tert-octyl polysulfide (sulfur content: 37% by mass, presence ratio of sulfur bridging number 4 or more: 70 mol%), (A1-2) di-tert-octyl polysulfide (sulfur content : 37% by mass, presence ratio of 4 or more sulfur bridges: 70 mol %) and (A1-3) di-second...

Embodiment 2 and comparative example 2

[0121] Table 2 shows the compounding amounts and properties of various lubricating base oils and additives. The blending amount (mass %) of the base oil and the addition amount (mass %) of each additive are based on the total amount of the lubricating oil composition.

[0122] For each of the obtained compositions, processability was evaluated by a tapping test and a copper plate corrosion test.

[0123] The sulfurized esters A and B are obtained by sulfurizing methyl linoleate or ethyl linoleate to obtain sulfurized esters, and extracting the sulfurized esters with a silica gel-based gel chromatography. In the extracted portion, the content of the compound having a sulfur bridging number of 3 or more was less than 5% by mass based on the sulfur element content.

[0124] [Table 2]

[0125]

Embodiment 3 and comparative example 3

[0127] Table 3 shows the compounding amounts and properties of various lubricating base oils and additives. The blending amount (mass %) of the base oil and the addition amount (mass %) of each additive are based on the total amount of the lubricating oil composition.

[0128] In addition, the lubricating oil composition described in Comparative Example 3-4 is a lubricating oil composition of the present invention, and is given as a comparative example for showing the effect of adding the component [A3].

[0129] For each of the obtained compositions, a threading test and a turbidity evaluation test were performed. Three kinds of sulfurized ester compounds were prepared by the following methods.

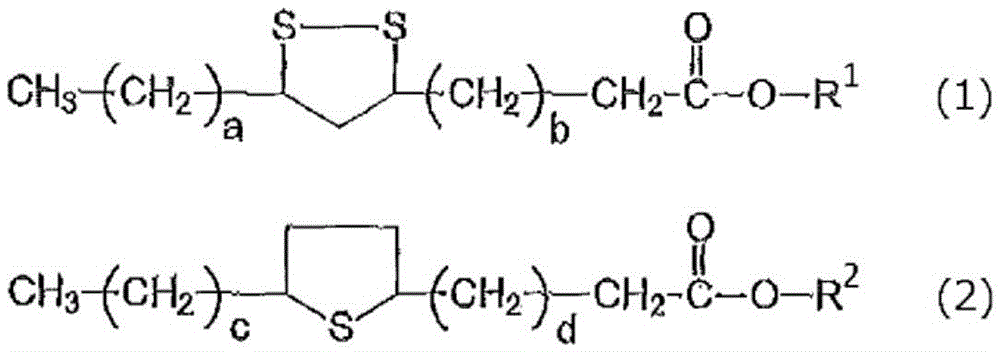

[0130] [A2-3]: Cyclic sulfide esters represented by formulas (1) and (2) (R 1 , R 2 =CH3 , a+b=12, c+d=11, the mixing ratio is 50:50 in terms of mass ratio)

[0131] 150 g of silica gel was plugged into the glass tube, and then 1.5 g of sulfurized ester (M10 manufactured by DOG C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com