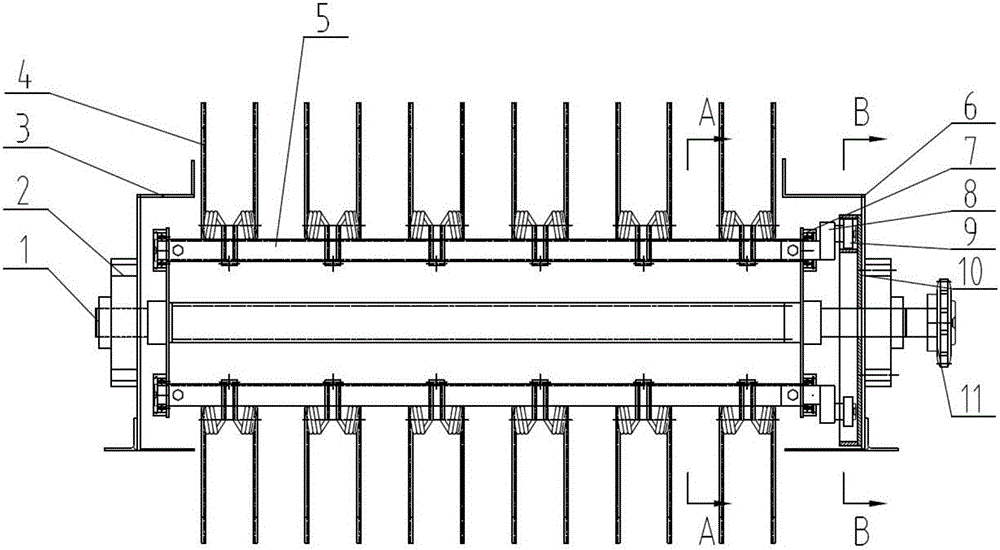

Spring tooth roller type peanut pickup device

A drum-type, spring-tooth technology, used in loaders, excavators, agricultural machinery and implements, etc., can solve the problems of high loss, throwing, missed picking rate and fruit drop rate, and achieve high elastic limit and yield. Strong ratio, not easy to be permanently deformed, and the effect of reducing the frequency of replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

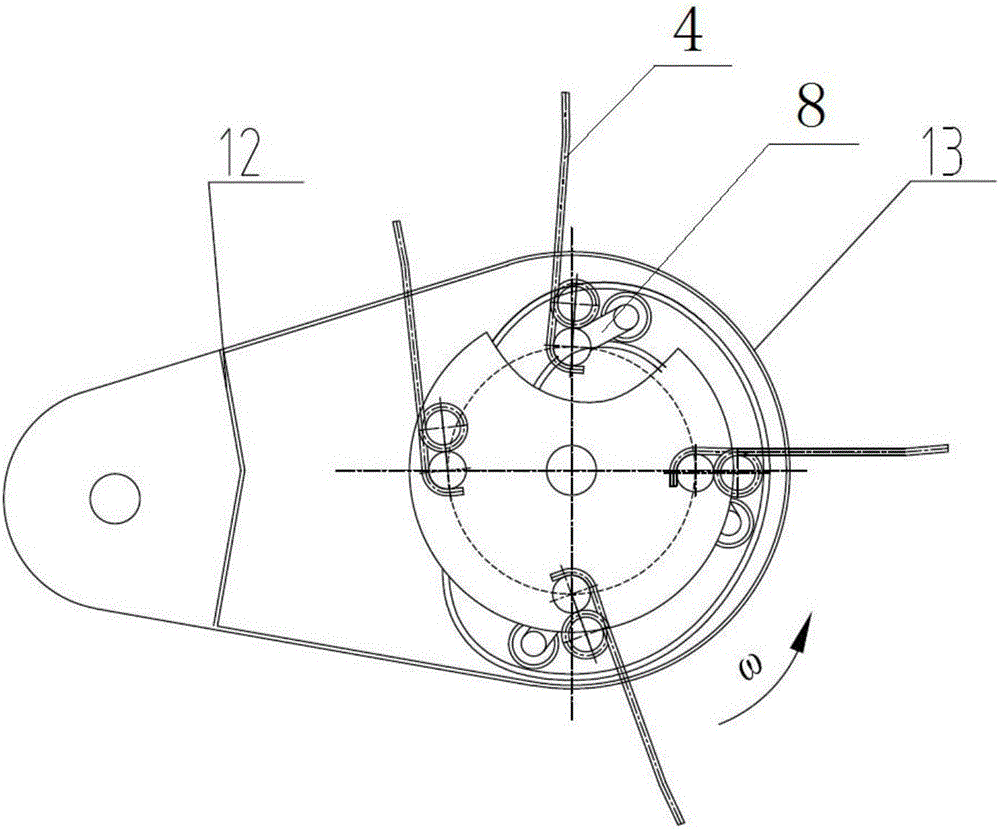

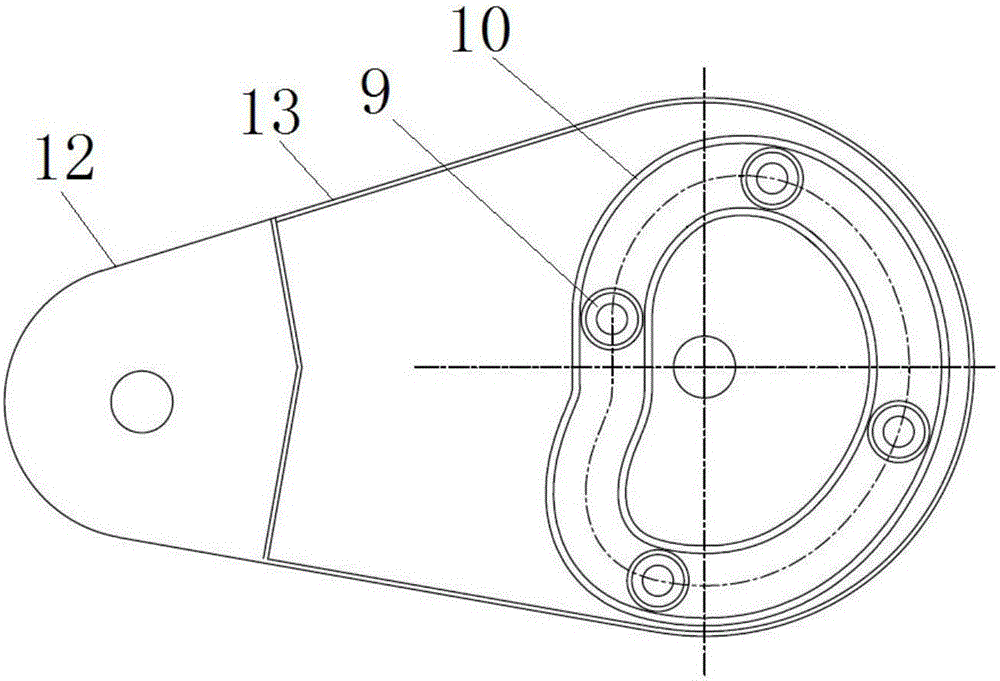

[0031] Embodiment 1: The present invention combines the typical peanut varieties in Northeast my country, the agronomic characteristics of planting and two-stage harvesting and based on the principle of bionics, starting from the analysis of the ideal posture and motion law of the peanut picking element, and researching the core of the slide-type spring-toothed roller picking device The mechanism is the spring tooth picking mechanism, and the mechanism parameters are optimized. Preliminarily determine the center line trajectory of the cam slideway according to the swinging law of the spring teeth, determine the optimization objective function according to the picking characteristics of the peanut plant and the motion characteristics of the mechanism, deduce the geometric relationship between each parameter in the mechanism and the objective function, and use the objective optimization algorithm to optimize the mechanism parameters. Obtain the ideal mechanism parameter combinatio...

Embodiment 2

[0049] Embodiment 2: The difference between this example and Embodiment 1 is that in this example, the initial pick-up inclination angle θ of the pick-up station is 25°, and the four phase angles are sequentially β along the clockwise direction. 1 = 85°, β 2 = 100°, β 3 =98°, β 4 =77°; the angle between the pick-up tooth and the crank axis is 55°. There is a gap of 30mm between adjacent guard plates to ensure that the picking spring teeth can extend and retract between the guard plates. The radian of the inclination angle γ of the upper guard plate relative to the horizontal plane of the drum is 0.26 rad, and when the push station is in contact with the upper guard plate, the included angle α between them is 76°. The crank length is 50mm; the pick-up teeth length is 203mm. x 1 -35mm, Y 1 is 36mm.

Embodiment 3

[0050] Embodiment 3: The difference between this example and Embodiment 1 is that in this example, the initial pick-up inclination angle θ of the pick-up station is 25°, and the four phase angles are sequentially β along the clockwise direction. 1 = 80°, β 2 =95°, β 3 =110°, β 4 =75°; the angle between the pick-up tooth and the crank axis is 58°. There is a gap of 28mm between adjacent guard plates to ensure that the pick-up teeth extend and retract between the guard plates. The radian of the inclination angle γ of the upper guard plate relative to the horizontal plane of the drum is 0.21 rad, and when the push station is in contact with the upper guard plate, the included angle α between them is 79.5°. The crank length is 50mm, and the pick-up tine length is 203mm. x 1 -41mm, Y 1 is 29mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

| Radian | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com