Reflective paper bag, reflective paper bag roller coating machine and production process of reflective paper bag

A production process and technology of roller coating machine, which is applied to the device for coating liquid on the surface, coating, gardening, etc. It can solve the problems of unsatisfactory use effect and single structural design, and achieve the reduction of star point cracking and good air permeability , the effect of reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

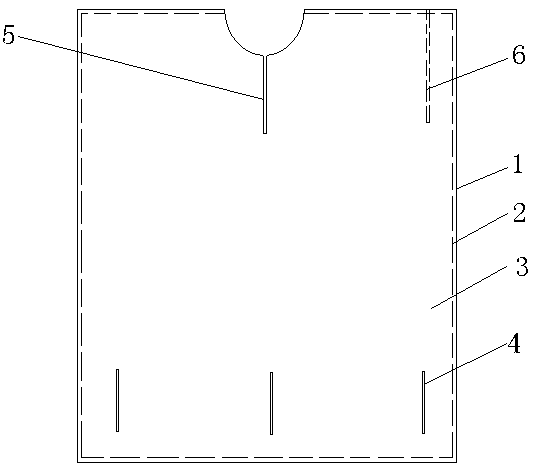

[0036] The reflective paper bag of present embodiment, refer to attached figure 1 , including a paper bag 1 with an open top, a light-shielding film 2 is arranged inside the paper bag 1, a tin foil powder coating 3 is covered on the outer surface of the paper bag 1, and an air vent 4 for improving air permeability is opened on the paper bag 1, and the top of the paper bag 1 The opening is provided with a fruit handle opening 5 for passing through the fruit handle, and a binding iron wire 6 is installed on the upper position of one side of the paper bag 1 .

Embodiment 2

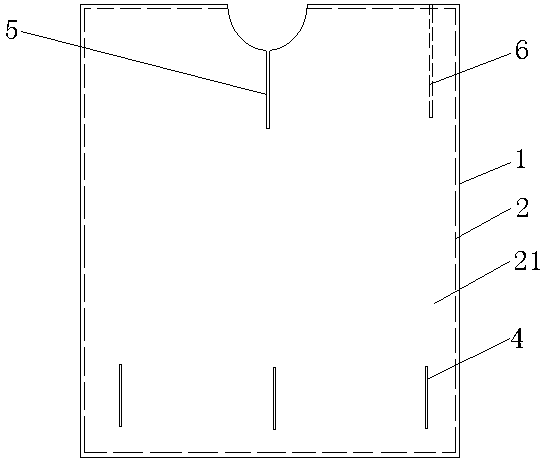

[0038] The difference between this embodiment and Embodiment 1 is that: the outer surface of the paper bag 1 is covered with an aluminum-silver paste layer 21.

Embodiment 3

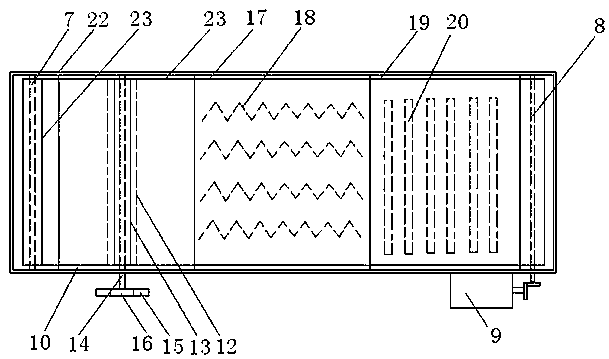

[0040] The reflective paper bag roller coater of present embodiment, refer to attached Figure 3-4 , comprising a frame body 22, the top of the frame body 22 is installed successively from left to right for winding the secondary turning roller 7 of the fruit bag paper 23, for carrying out the roller coating device for the surface coating of the fruit bag paper 23, for drying the fruit A drying device for bag paper 23, a drying and sterilizing device for further drying and sterilization, a main rotating roller 8 used in conjunction with the rotating roller 7, and the main rotating roller 8 is connected and driven by a motor 9, wherein the roller The coating device includes a feed box 10 installed on the frame body 22, a lower shaft 11 is installed in the feed box 10, one end of the lower shaft 11 is axially connected to the feed box 10, and the other end of the lower shaft 11 is located outside the feed box 10, The end of the lower shaft 11 located outside the material box 10 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com