Direct-current intelligent coating equipment used for rail

An intelligent and coating technology, used in track lubrication, railway auxiliary equipment, track wetting/lubrication, etc., can solve the problems of running safety of battery-depleted trains, weak generator power generation, poor performance of oiling equipment, etc. To achieve the effect of saving manpower and material resources, easy installation, maintenance and replacement, easy operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

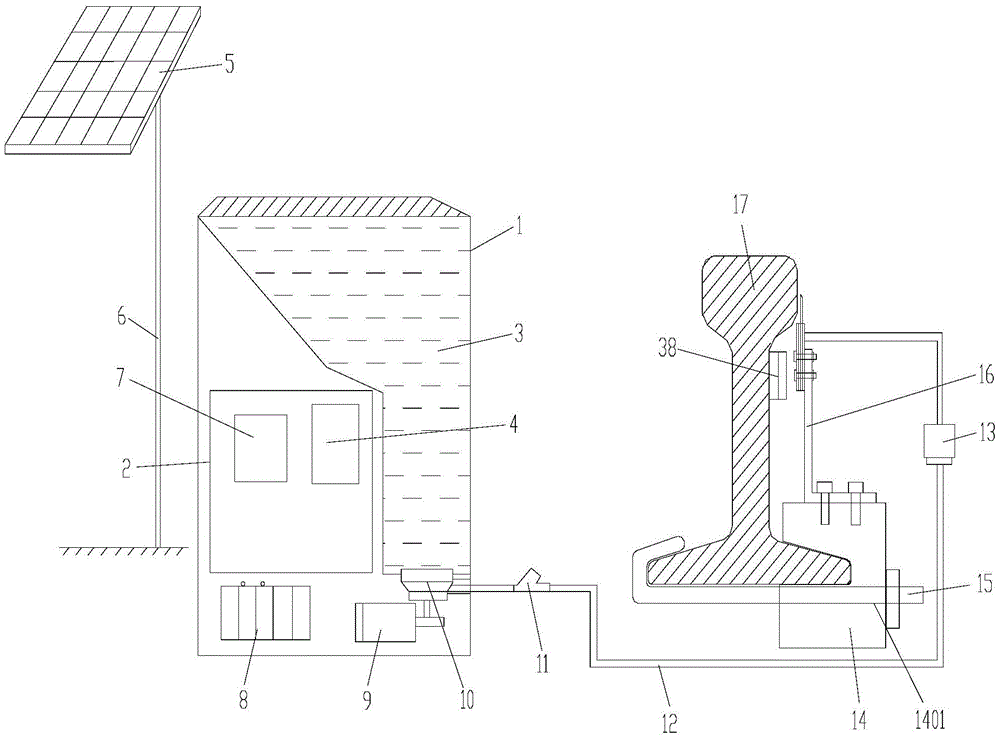

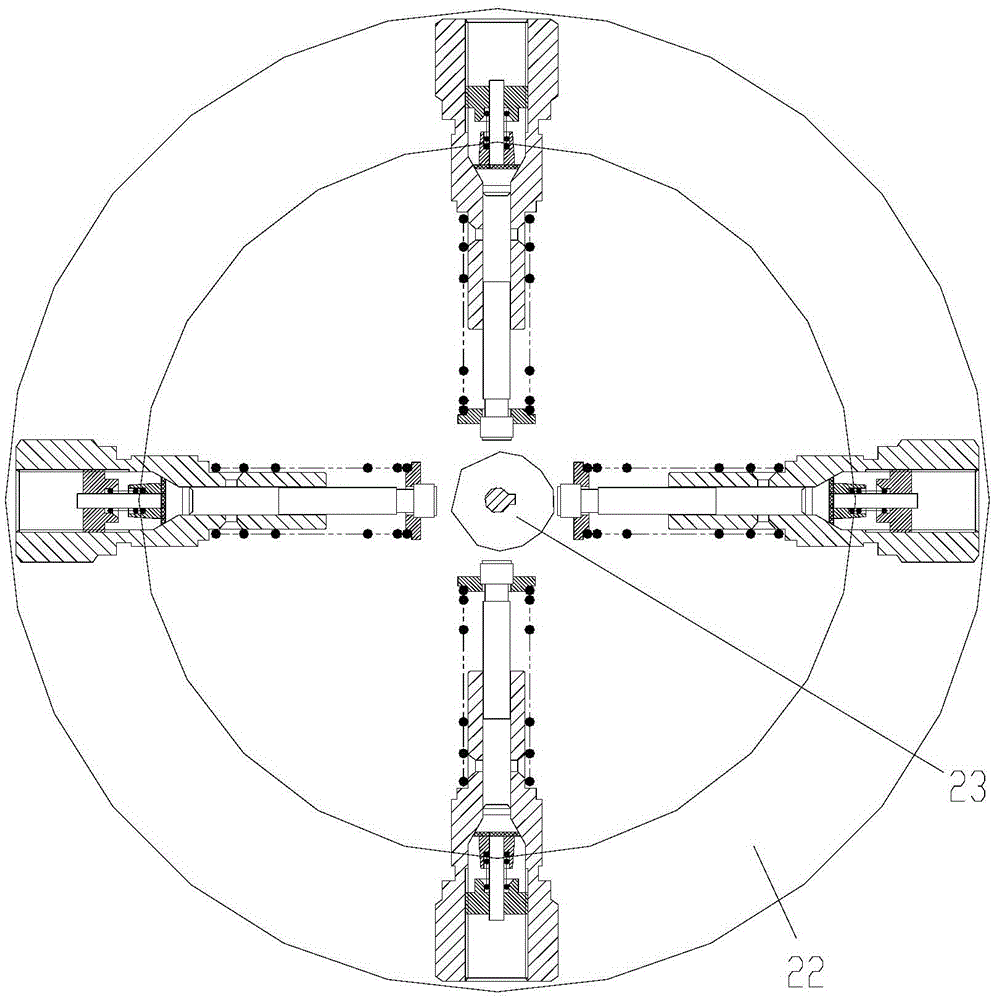

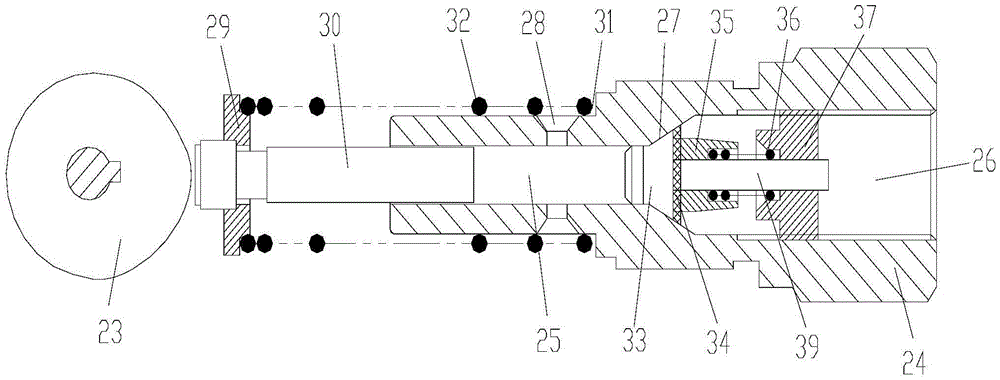

[0030] Attached below Figure 1-9 Embodiments of the present invention are described.

[0031] DC intelligent coating equipment for rails, such as figure 1As shown, it includes a box body 1, a photovoltaic energy storage component and a coated panel component. The inside of the box body 1 is provided with a control box 2 and a grease storage box 3. The inside of the control box 2 is provided with a charge and discharge controller 7 and an automatic Control system 4, a storage battery 8 is arranged in the box body 1 and the lower part of the control box 2, a grease pump 10 is fixed on the bottom plate of the grease storage box 3, a motor 9 is fixed at the bottom of the grease storage box 3, and the motor 9 9 is a DC low-voltage motor, which is safe and convenient to use. The coating plate assembly is fixed on one side of the rail 17 through the coating plate fixing device. The output shaft of the motor 9 is fixedly connected to the input end of the grease pump 10. The grease p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com