Cleaning retort used for silicon carbide impurity removal

A silicon carbide and reaction tank technology, applied in the field of cleaning reaction tanks, can solve problems such as unsatisfactory iron removal effect, and achieve the effects of preventing corrosion of plant equipment, avoiding pollution, and preventing a large number of adhesion deposits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

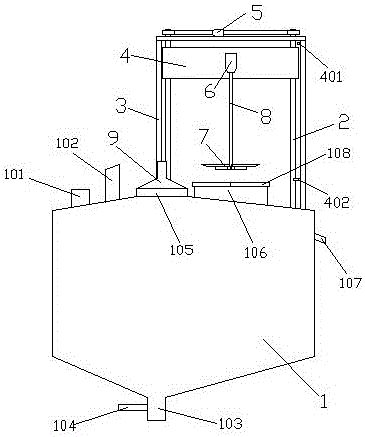

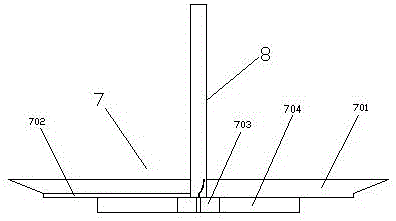

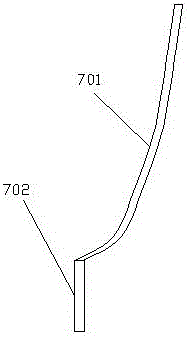

[0016] As shown in the figure, a cleaning reaction tank for silicon carbide removal includes a tank body 1, the top of the tank body 1 is provided with a slurry inlet 101 and an acid inlet pipe 102, and the bottom is provided with a slurry outlet 103, so The top of the tank body 1 is arched, and a plastic connecting pipe 105 is provided at the highest point of the arch, and the plastic connecting pipe 105 is connected with a negative pressure source through an acid mist collecting cover 9 to collect the acid gas in the tank body 1; The top of the tank body 1 is provided with an elevating stirring device through the gantry 3, and the elevating agitating device includes two screw rods 2 vertically fixed on the gantry 3, and the bottoms of the two screw rods 2 are rotated and fixed on the The top of the tank body 1 and the top of the screw rod 2 are connected to the lifting motor 5 through a pulley, and a lifting frame 4 is arranged between the two screw rods 2, and the lifting fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com