Method for preparing acetylene-modified alkylphenol formaldehyde super-tackifying resin

A super tackifying resin and tackifying resin technology, applied in the chemical industry, can solve the problems of solvent and waste water generation, reduced tackifying performance, complex production process, etc., and achieve the effect of low reaction pressure, less reaction volume and short process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

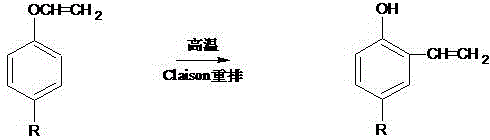

Method used

Image

Examples

Embodiment 1

[0025] The present invention is put into trial production in our company. The preparation method of the acetylene-modified alkylphenol formaldehyde super tackifying resin is characterized in that: firstly, the p-tert-butylphenol paraformaldehyde tackifying resin is prepared by reacting p-tert-butylphenol and paraformaldehyde with catalyst oxalic acid; and then Use acetylene and p-tert-butylphenol paraformaldehyde tackifying resin to adopt catalyst zinc alkanoate reaction to prepare acetylene-modified p-tert-butylphenol paraformaldehyde super tackifying resin; its production steps are:

[0026] (1) Preparation of p-tert-butylphenol paraformaldehyde tackifying resin:

[0027] A. Add p-tert-butylphenol and paraformaldehyde into the reactor at a molar ratio of 1:0.98. The formaldehyde is completely melted, and the catalyst oxalic acid is added when the temperature is lowered to 90°C. The input amount is: the mass ratio of p-tert-butylphenol to the catalyst oxalic acid is 100:2, a...

Embodiment 2

[0035] The present invention is put into trial production in our company. The preparation method of the acetylene-modified alkylphenol formaldehyde super tackifying resin is characterized in that: firstly, p-tertoctylphenol and paraformaldehyde are reacted with catalyst oxalic acid to prepare p-tertoctylphenol paraformaldehyde tackifying resin; Then adopt acetylene and p-tert-octylphenol paraformaldehyde tackifying resin to adopt catalyzer zinc naphthenate reaction to prepare the p-tert-octylphenol paraformaldehyde super tackifying resin of acetylene modification; Its production step is with embodiment 1 ,in:

[0036] (1) Preparation of p-tertoctylphenol paraformaldehyde tackifying resin:

[0037] A. Add p-tetraoctylphenol and paraformaldehyde into the reactor at a molar ratio of 1:1. The paraformaldehyde is completely melted, and the catalyst oxalic acid is added when the temperature is lowered to 90°C. The input amount is: the mass ratio of p-tertoctylphenol to the catalys...

Embodiment 3

[0046] The present invention is put into trial production in our company. The preparation method of the acetylene-modified alkylphenol formaldehyde super tackifying resin is characterized in that: firstly, the p-tert-butylphenol paraformaldehyde tackifying resin is prepared by reacting p-tert-butylphenol and paraformaldehyde with catalyst oxalic acid; and then Adopt catalyzer zinc acetate reaction to prepare acetylene modified p-tert-butylphenol paraformaldehyde super tackifying resin with acetylene and p-tert-butylphenol paraformaldehyde tackifying resin; Its production steps are with embodiment 1, wherein:

[0047] (1) Preparation of p-tert-butylphenol paraformaldehyde tackifying resin:

[0048] In the step A, the molar ratio of p-tert-butylphenol to paraformaldehyde is 1:0.95.

[0049] (2) Preparation of acetylene-modified p-tert-butylphenol paraformaldehyde super tackifying resin:

[0050] In the step A, the mass ratio of p-tert-butylphenol to the catalyst zinc acetate i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com