Near-full-spectrum fluorescent nanocarbon dots and preparation method thereof

A fluorescent nanometer and full-spectrum technology, applied in the field of carbon nanoluminescent materials, can solve the problems of no synthetic fluorescent carbon dots, etc., and achieve the effects of easy industrial production, cheap and easy-to-obtain sources, and low synthesis cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

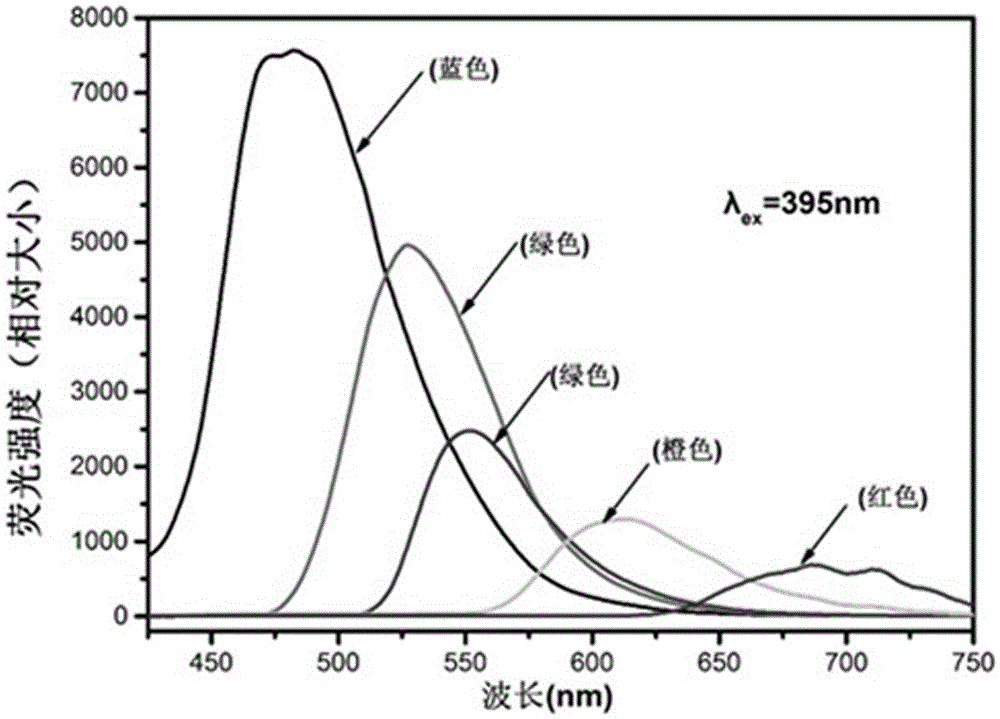

[0031] Take monoethanolamine and citric acid at a molar ratio of 1:0.05, add deionized water to dissolve, stir evenly, transfer to a hydrothermal kettle, and conduct a hydrothermal reaction at 160°C-250°C for 5h-24h. After the reaction is completed, Let the hydrothermal kettle cool down to room temperature naturally, and the blue solution can be obtained, which is the carbon dot aqueous solution. After the carbon dot aqueous solution is subjected to high-speed centrifugation at 16,000 rpm to remove impurities, it is then placed in a vacuum drying oven to remove carbon by vacuum drying. Point most of the water in the aqueous solution, and the final solution is the carbon dot solution. Take the excitation wavelength of 395nm as an example to test the spectrum.

Embodiment 2

[0033] Take monoethanolamine and citric acid at a molar ratio of 1:0.20, add deionization to dissolve, stir evenly, transfer to a hydrothermal kettle, and conduct a hydrothermal reaction at 160°C-250°C for 5h-24h. After the reaction is completed, make The hydrothermal kettle is naturally cooled to room temperature, and the green solution can be obtained, which is the carbon dot aqueous solution. After the carbon dot aqueous solution is removed by high-speed centrifugation at 16,000 rpm, it is then placed in a vacuum drying oven to remove the carbon dot aqueous solution by vacuum drying. Most of the water in the solution, the final solution is the carbon dot solution. Take the excitation wavelength of 395nm as an example to test the spectrum.

Embodiment 3

[0035] Take monoethanolamine and citric acid at a molar ratio of 1:0.18 or 1:0.23, add deionized water to dissolve, stir evenly, transfer to a hydrothermal kettle, and conduct a hydrothermal reaction at 160°C-250°C for 5h-24h. After the reaction is completed, let the hydrothermal kettle cool down to room temperature naturally, and the green solution can be obtained, which is the carbon dot aqueous solution. Drying removes most of the water in the carbon dot aqueous solution, and the final solution is the carbon dot solution. Taking the excitation wavelength of 395nm as an example, the spectrum is tested.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com