A device and process for producing bio-oil by hydrothermal liquefaction of microalgae extracted from power plants

A hydrothermal liquefaction and bio-oil technology, applied in the petroleum industry, liquid carbon-containing fuels, fuels, etc., can solve the problems of high energy consumption and low heating rate, and achieve the effects of saving energy consumption, improving quality, and rapidly heating up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

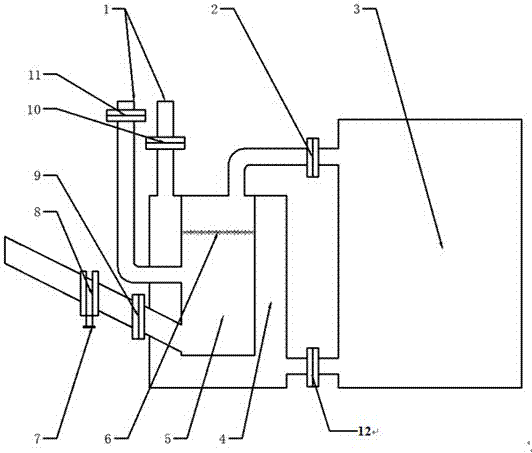

[0032] The microalgae and ethanol are prepared according to the ratio of 1:8 to prepare the microalgae pulp. Each feeding amount is 1 / 3 of the volume of the interlayer 5 in the autoclave;

[0033] After the HZSM-5 catalyst is placed, start feeding. After the two-stage feeding is completed, hydrogen gas is introduced into the inner compartment 5 of the autoclave through the pneumatic conveying port 7, and the air in the inner compartment 5 of the autoclave is replaced twice to discharge the air;

[0034] Open the steam supply valve 11 of the inner compartment of the autoclave and the steam supply valve 10 of the outer compartment of the autoclave, and the four-pumped water steam of the steam turbine is divided into two ways to convey, and it is passed into the inner compartment 5 and the outer compartment 4 of the autoclave, and the inner layer of the autoclave 5 After reaching the pressure balance with the water vapor, close the valve 11 of the inner compartment of the autocla...

Embodiment 2

[0037] Prepare microalgae and ethanol at a ratio of 1:12 to prepare microalgae pulp. Each feeding amount is 2 / 3 of the volume of the interlayer 5 in the autoclave;

[0038] After placing the HZSM-5 catalyst, start feeding. After the two stages of feeding are completed, hydrogen gas is introduced into the inner compartment 5 of the autoclave through the pneumatic conveying port 7, and the air in the inner compartment 5 of the autoclave is replaced 3 times to discharge the air;

[0039] Open the steam supply valve 11 of the inner compartment of the autoclave and the steam supply valve 10 of the outer compartment of the autoclave, and the four-pumped water steam of the steam turbine is divided into two ways to convey, and it is passed into the inner compartment 5 and the outer compartment 4 of the autoclave, and the inner layer of the autoclave 5 After reaching the pressure balance with the water vapor, close the valve 11 of the inner compartment of the autoclave to stop the stea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com